Mechanical and electrical integration linear driving device

A linear drive, electromechanical technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of high processing costs and procurement costs, reduced transmission accuracy of linear drive devices, complex equipment maintenance, etc., to reduce processing Control nodes, reduce assembly workload and process difficulty, and improve the effect of IP level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

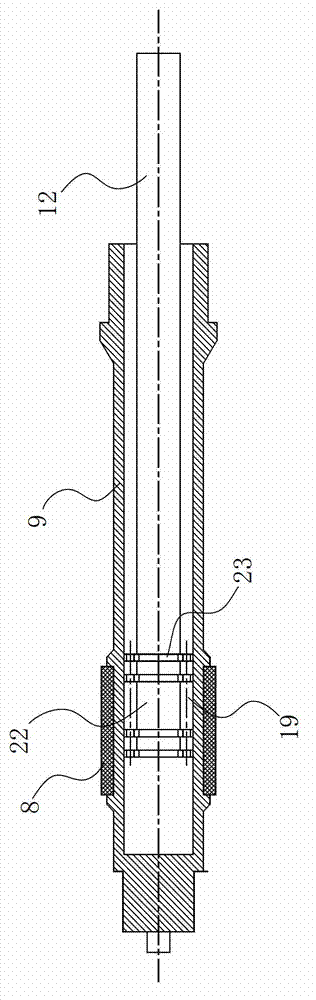

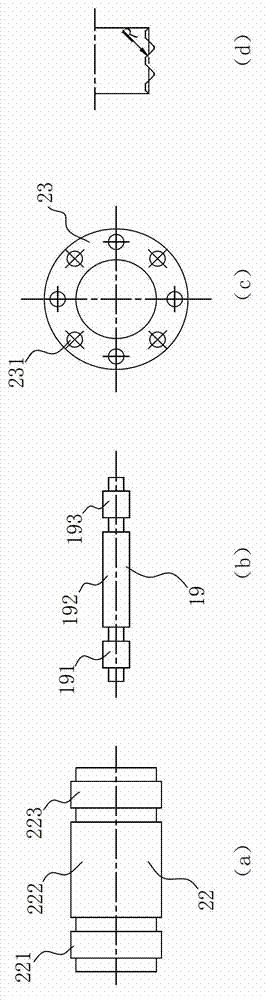

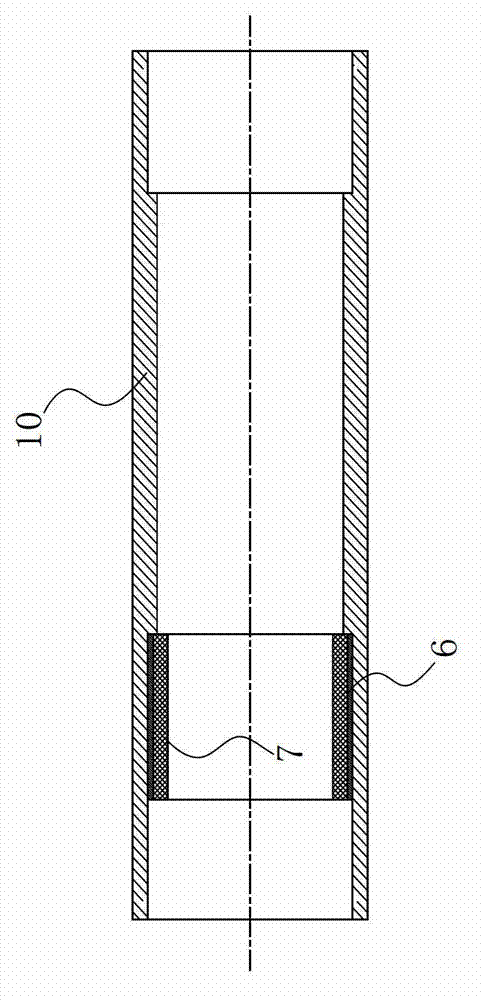

[0034] Such as Figures 1 to 4 The shown linear drive device includes an output shaft 12 and a lead screw pair, the output shaft 12 and the lead screw 22 of the lead screw pair are fixed through threaded connection, and the described device includes a cylinder body 10, and the stator assembly is fixed inside the cylinder body 10; The lead screw nut 9 of the lead screw pair is long cylindrical, and the rotor assembly matched with the stator assembly is fixed outside the lead screw nut 9 . As for ensuring the operation of the lead screw pair, it is necessary to fix the lead screw nut 9 of the lead screw pair with a bearing, and at the same time position the output shaft 12 that needs axial movement, then there are many embodiments that can be realized. Usually: the lead screw nut 9 and the output shaft 12 of the lead screw pair are respectively positioned through bearings; Rotational motion, output shaft 12 can do linear motion under the drive of lead screw 22 and get final pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com