External operation handle device for a circuit breaker

A technology of external operation and circuit breaker, which is applied in the direction of circuit breaker parts, circuits, contact operating parts, etc., can solve the problems of increased product cost and increased assembly workload, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

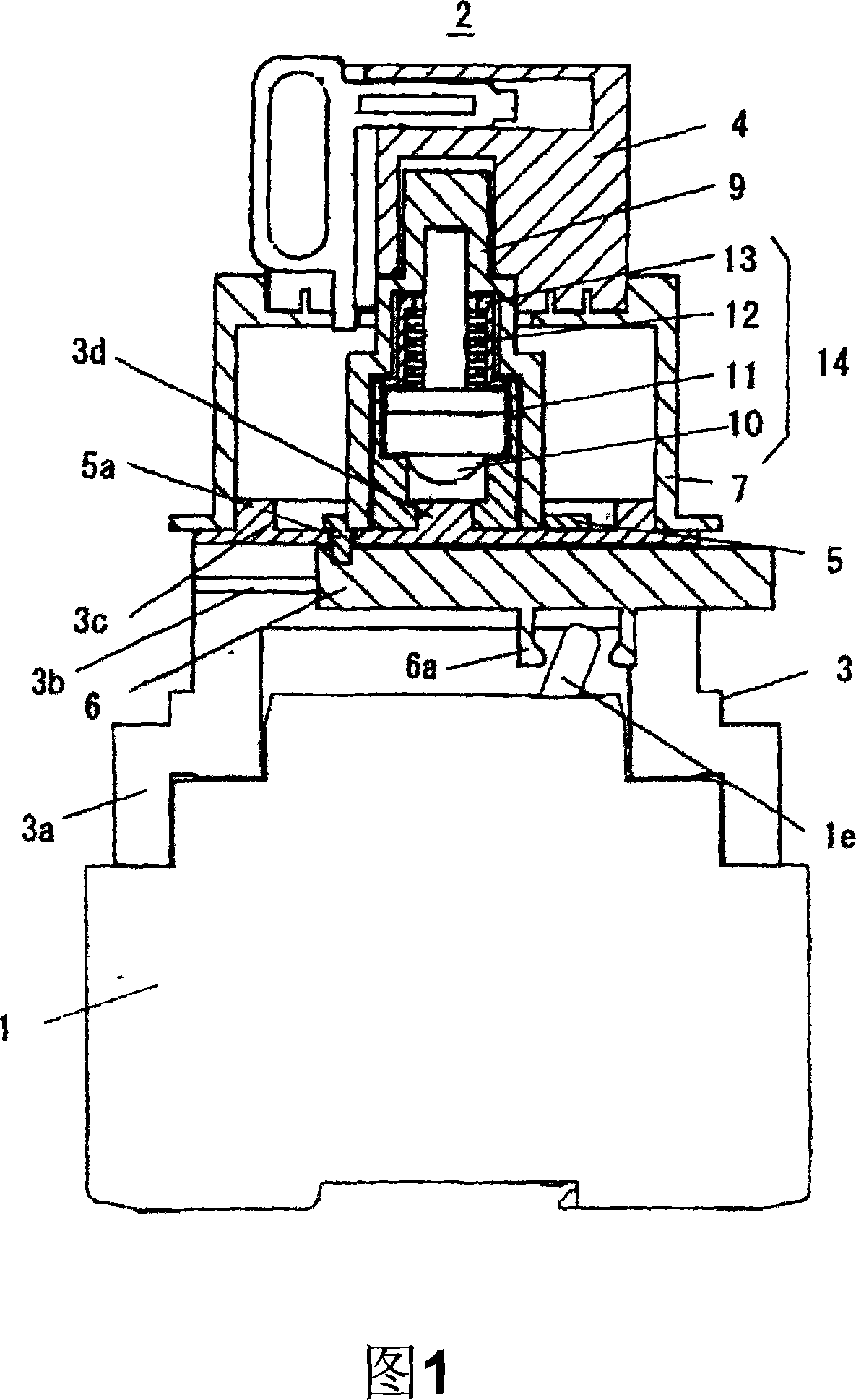

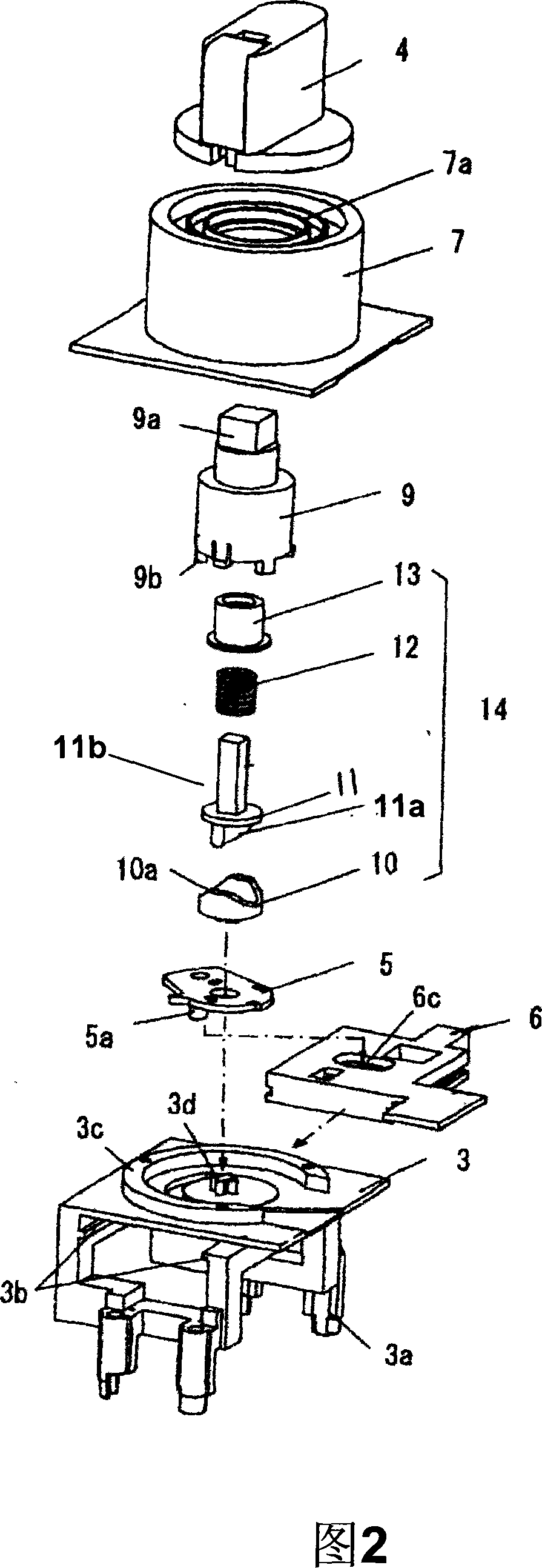

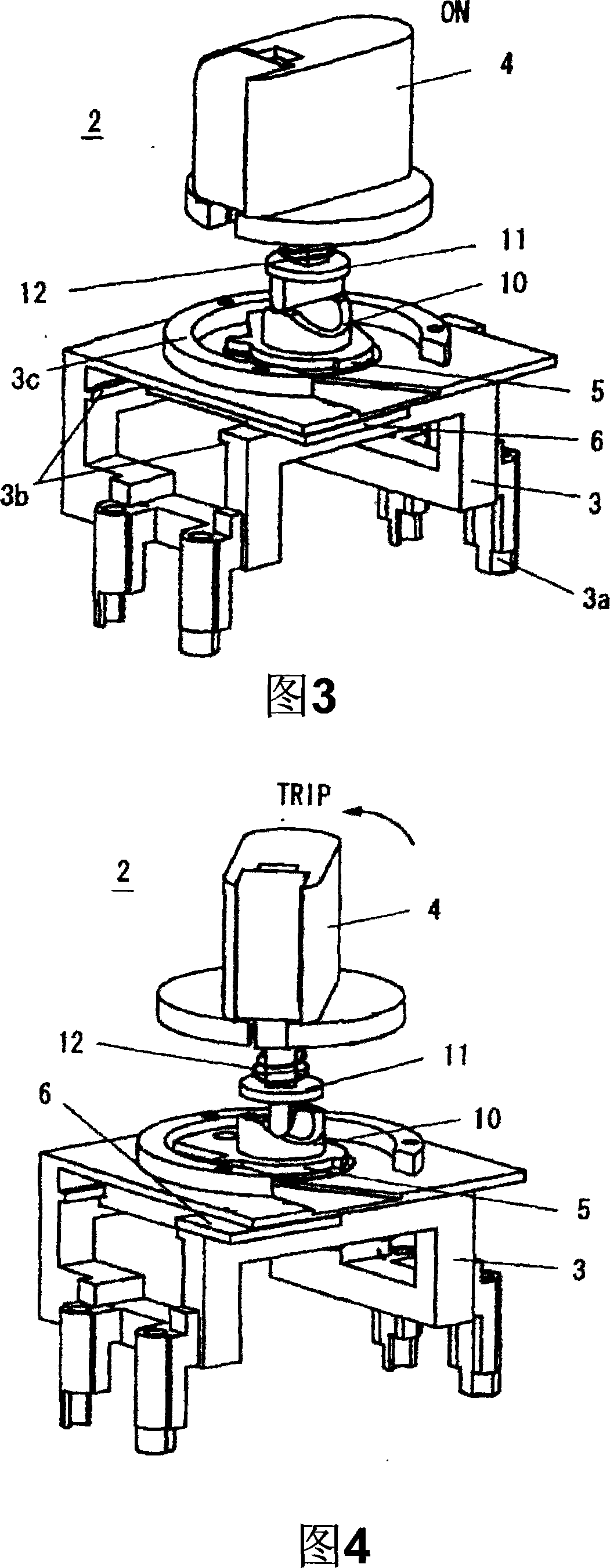

[0032] Hereinafter, the embodiments of the present invention will be described based on the examples shown in FIGS. 1 to 4. Among them, in the drawings of the embodiment, the same reference numerals are given to the parts corresponding to FIGS. 5 to 8 and the description thereof is omitted.

[0033] That is, in the external operation handle device 2 of the illustrated embodiment, the handle handle 4 and the rotating seat 5 are connected via the connecting shaft 9 of the hollow structure, and the handle handle 4 and the rotating seat 5 are connected to the inner side of the hollow connecting shaft 9 An auxiliary mechanism 14 composed of an assembly of the cam body 10, the cam follower 11, the biasing spring 12, and the spring cover 13 is installed and arranged in between.

[0034] Here, as shown in the exploded view of FIG. 2, the hollow connecting shaft 9 pushes the prismatic shaft portion 9a at its upper end into the engaging hole opened on the lower surface of the handle 4, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com