Main wing surface structure of large aspect ratio wing

A technology with a large aspect ratio and wings, applied in the aviation field, can solve the problems of outstanding stability of the upper skin, poor shape of the thin skin, and unfavorable torque transmission, so as to shorten the development cycle and improve the structure. The level of integration and the effect of reducing assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

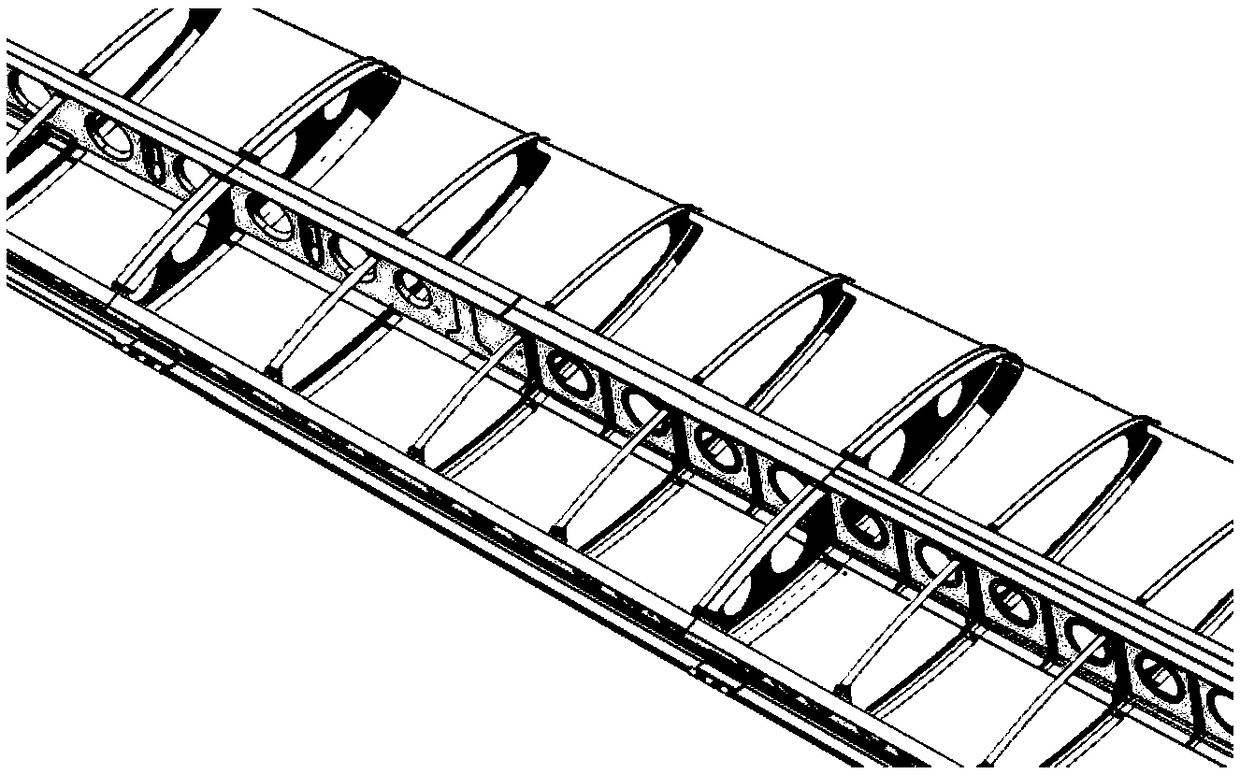

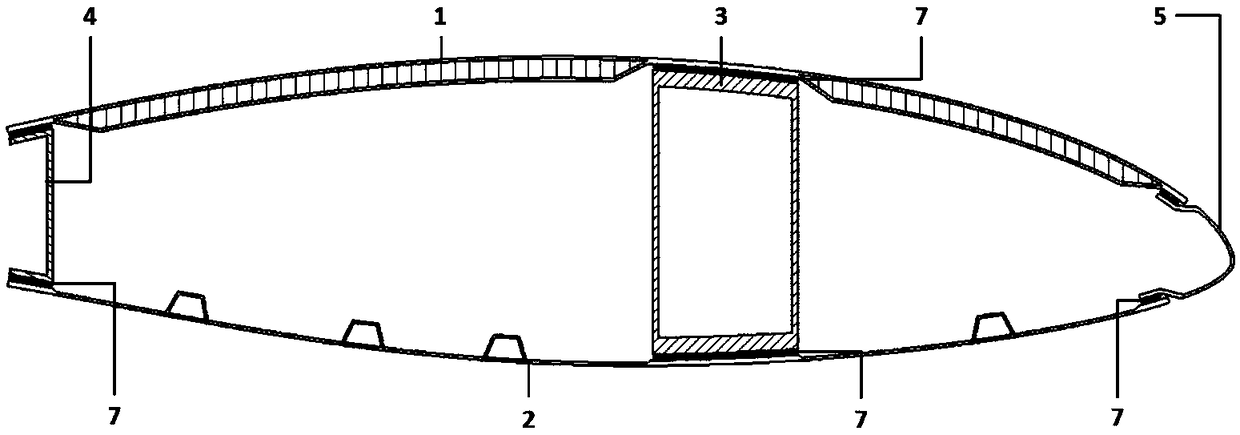

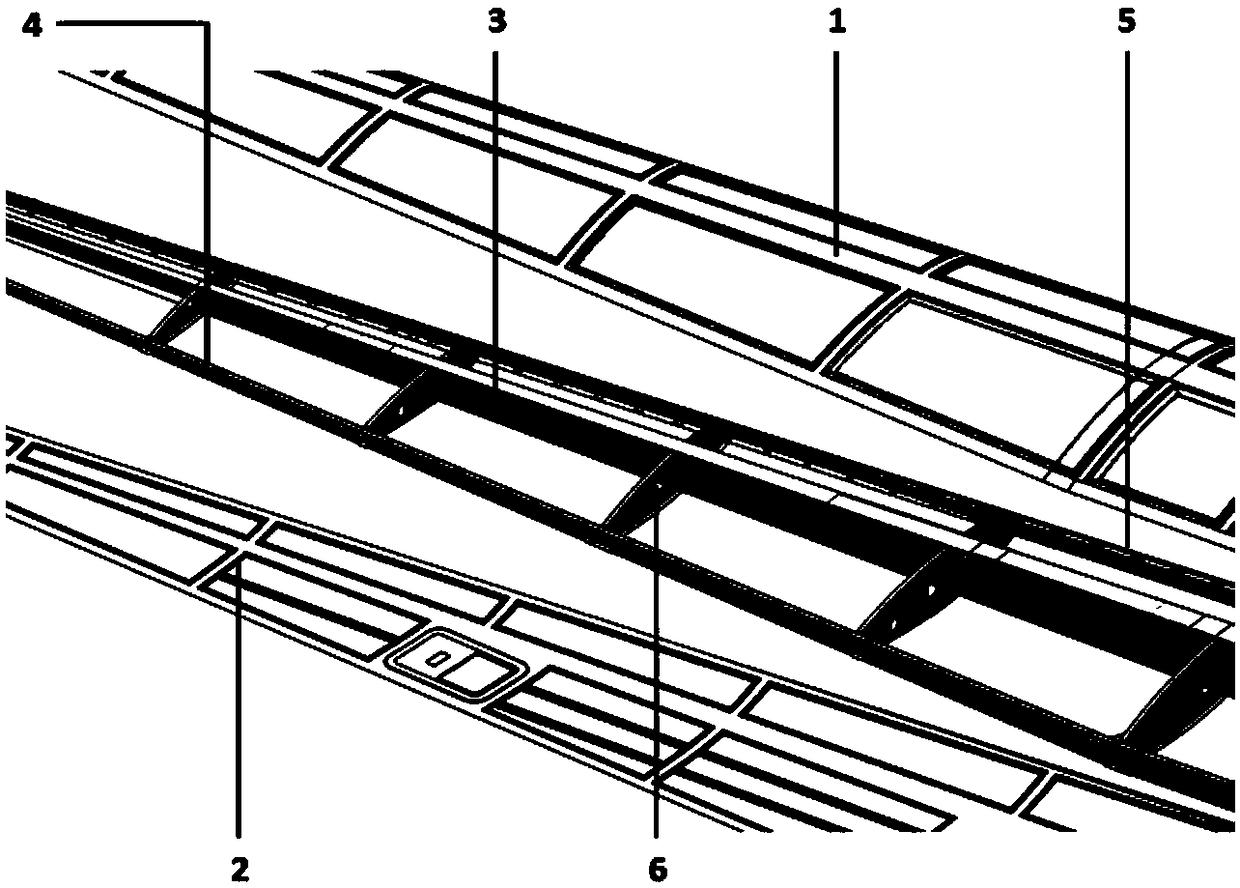

[0024] The main airfoil structure of a large aspect ratio wing described in the present invention is recommended to carry out parts manufacturing and assembly according to the following steps, see Figure 4 , Figure 5 :

[0025] (1) each of the component parts described above is solidified and formed;

[0026] (2) The box-type main beam 3, the rear wall 4, the front edge skin 5, and the wing rib 6 are assembled into an internal overall skeleton through tooling;

[0027] (3) The adhesive 7 is evenly coated on the upper surface of the internal overall skeleton, and the bonding with the upper wall panel 1 of the honeycomb interlayer is completed within the construction period of the adhesive 7;

[0028] (4) Evenly coat the adhesive 7 on the lower surface of the internal overall skeleton, and complete the bonding with the hat-shaped reinforced lower wall plate 2 within the construction period of the adhesive 7;

[0029] (5) Apply the contact pressure required for adhesive curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com