Polyphenylene sulfide composite material and preparation method thereof

A technology of polyphenylene sulfide and composite materials, applied in the field of polymer materials, can solve the problems of poor fluidity, low mechanical strength, and large loss of magnetic properties of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

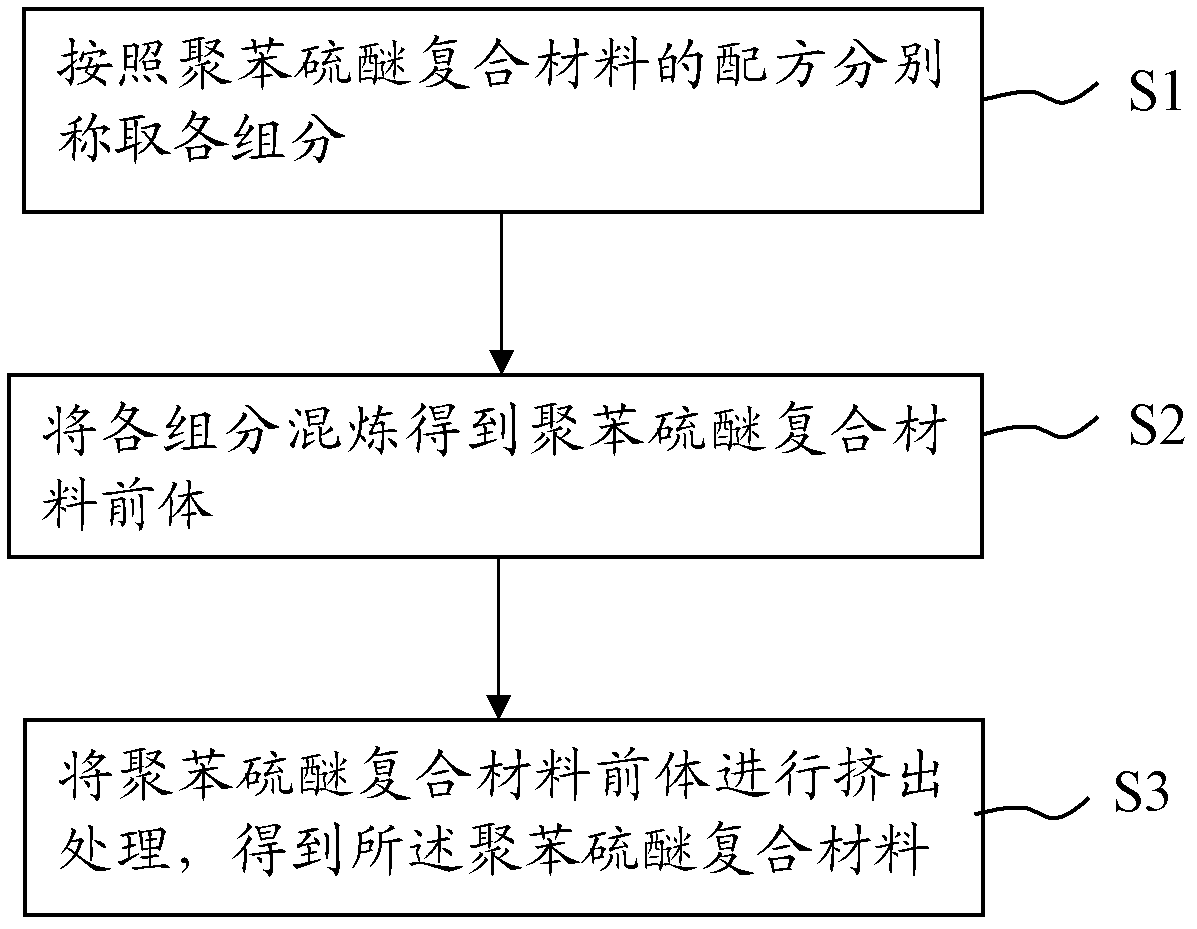

[0026] The embodiment of the present invention also provides the preparation method of above-mentioned polyphenylene sulfide composite material, and its technological process is as follows figure 1 shown. The method comprises the steps of:

[0027] S1: Weigh each component according to the formula of the above-mentioned polyphenylene sulfide composite material;

[0028] S2: mixing each component to obtain a polyphenylene sulfide composite material precursor;

[0029] S3: extruding the polyphenylene sulfide composite material precursor to obtain the polyphenylene sulfide composite material.

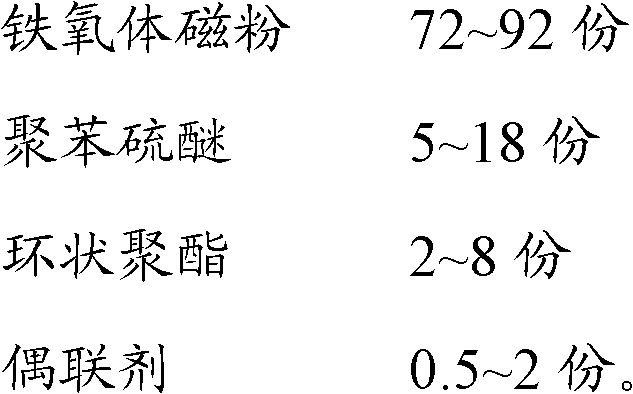

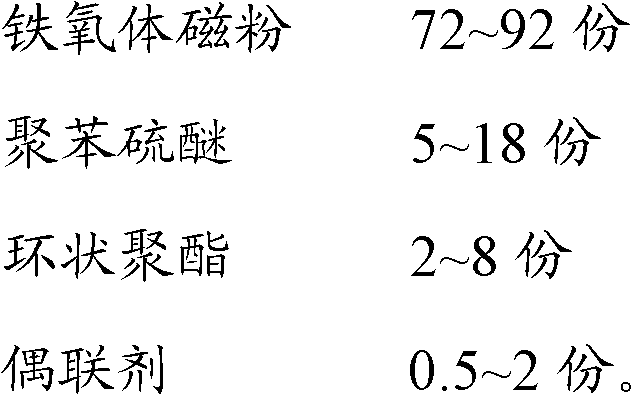

[0030] Specifically, in step S1 of the preparation method of the above-mentioned polyphenylene sulfide composite material, the ratio and types of the ferrite magnetic powder, polyphenylene sulfide, cyclic polyester, and coupling agent are all in the above-mentioned In order to save space, the detailed description is omitted. Among them, before weighing each component, it is preferable ...

Embodiment 1

[0038] Polyphenylene sulfide composite material parts by weight formulation components are as follows, see Table 1 at the same time:

[0039] The density is 3.0g / cm 3 74 parts of isotropic ferrite magnetic powder, 14 parts of PPS resin with molecular weight of 10000, 8 parts of cyclic polyester with molecular weight of 1000, 1 part of KH-5701, 0.25 part of antioxidant, 0.25 part of lubricant, 0.25 part of dispersant and 0.25 part of anti-ultraviolet agent.

[0040] The preparation method of the polyphenylene sulfide composite material comprises the following steps:

[0041] S11: Weigh each component according to the above formula;

[0042] S12: adding each component into an internal mixer and fully mixing for 15 minutes at a mixing temperature of 280° C. to obtain a polyphenylene sulfide composite material precursor;

[0043] S13: Put the polyphenylene sulfide composite material precursor into a twin-screw extruder to melt and knead, extrude, and granulate. The screw diamet...

Embodiment 2

[0045] Polyphenylene sulfide composite material parts by weight formulation components are as follows, see Table 1 at the same time:

[0046] The density is 6.0g / cm 3 80 parts of anisotropic ferrite magnetic powder, 12 parts of PPS resin with a molecular weight of 1000, 6 parts of cyclic polyester with a molecular weight of 1000, 1 part of KH-5701, 0.05 parts of antioxidant, 0.45 parts of lubricant, and 0.3 parts of dispersant And 0.2 parts of anti-ultraviolet agent.

[0047] The preparation method of the polyphenylene sulfide composite material comprises the following steps:

[0048] S21: Weigh each component according to the above formula;

[0049] S22: adding each component into an internal mixer and fully mixing for 18 minutes at a mixing temperature of 235° C. to obtain a polyphenylene sulfide composite material precursor;

[0050] S23: Put the polyphenylene sulfide composite material precursor into a twin-screw extruder to melt and knead, extrude, and granulate. The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com