Preparation method of coal-based magnetic activated carbon and coal-based magnetic activated carbon

A magnetic activated carbon and coal-based technology, which is applied to the preparation of coal-based magnetic activated carbon and the field of coal-based magnetic activated carbon, can solve the problems of reduced specific surface area, reduced specific surface area, small saturation magnetization, etc. Easy separation and recycling, stable magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

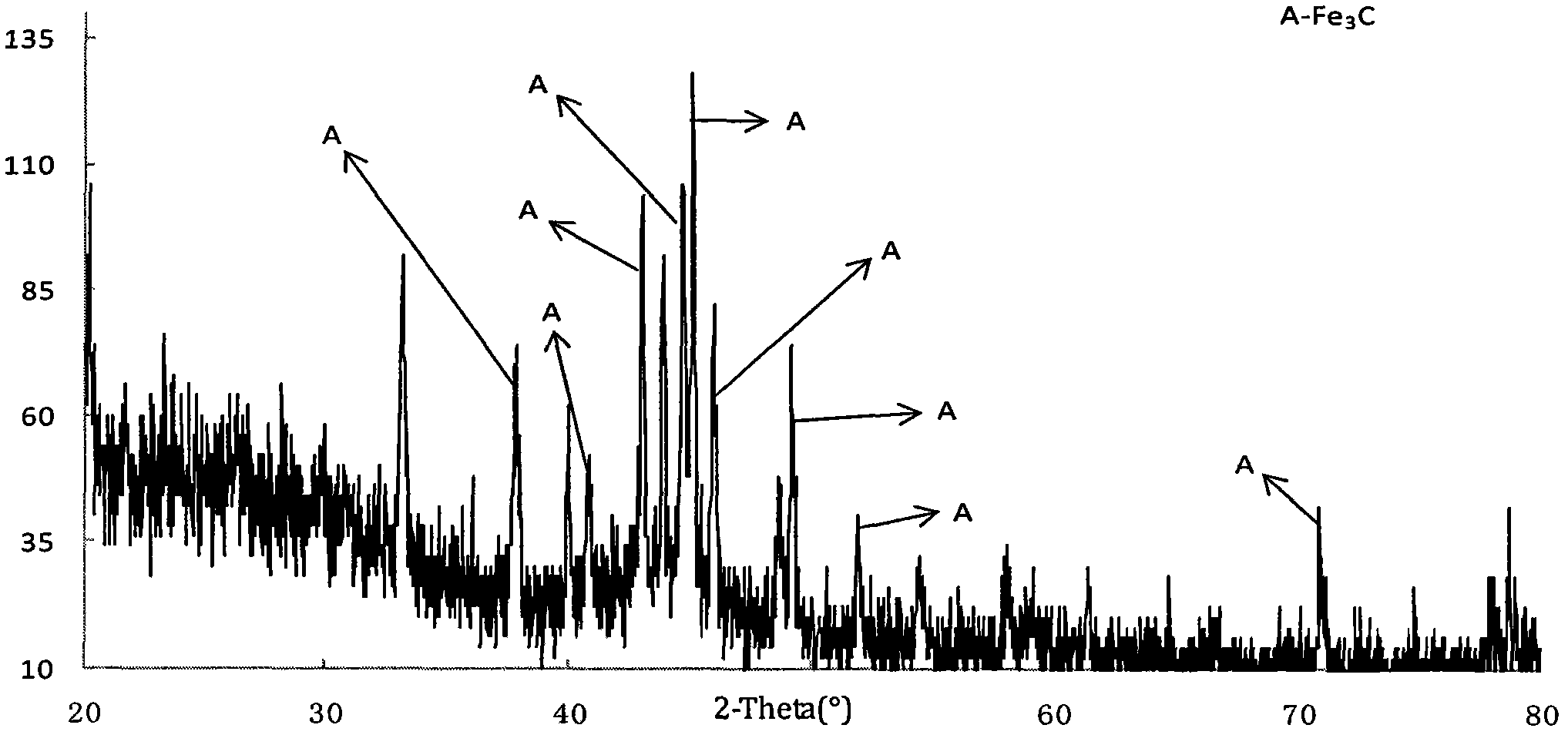

[0020] One, a kind of preparation method of coal-based magnetic activated carbon, this method is to directly prepare magnetic activated carbon with coal as base material, it is characterized in that, the coal as base material is that its particle size is the deashed coal powder that is less than or equal to 0.15mm, The method comprises the steps of:

[0021] Precursor preparation of magnetic activated carbon:

[0022] ①In the reaction vessel with ferric chloride solution, add the deashed coal powder and surfactant sodium dodecylsulfonate; after fully mixing, static adsorption, the time is not less than 3h; among them, the ferric chloride solution The mass concentration of the deashed coal powder: ferric chloride solution: =0.05-0.06g / mL is 5%-9%, and the mass ratio of the deashed coal powder to sodium dodecylsulfonate is between 40-75.

[0023] ② Mix ammonia water, sodium hydroxide solution or potassium hydroxide solution with the above mixed solution, stir well and let stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com