Imido magnetic nano-adsorbent as well as preparation method and application thereof

A technology of magnetic nanometers and magnetic nanoparticles, which is applied in chemical instruments and methods, separation methods, adsorption water/sewage treatment, etc., can solve problems such as imperfect synthesis methods, low adsorption rate of adsorbents, difficulty in heavy metal recovery, etc., and achieve Easy separation, stable magnetic properties, and reduced difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1:

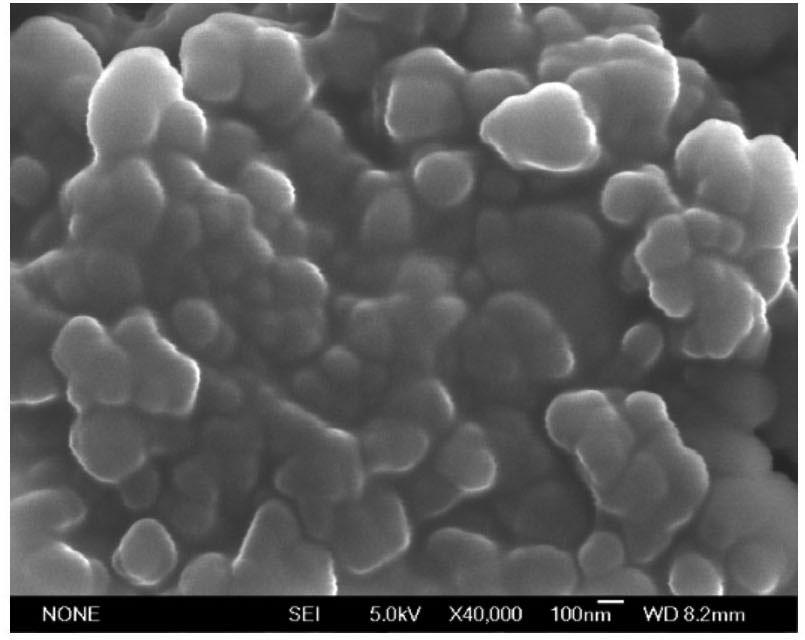

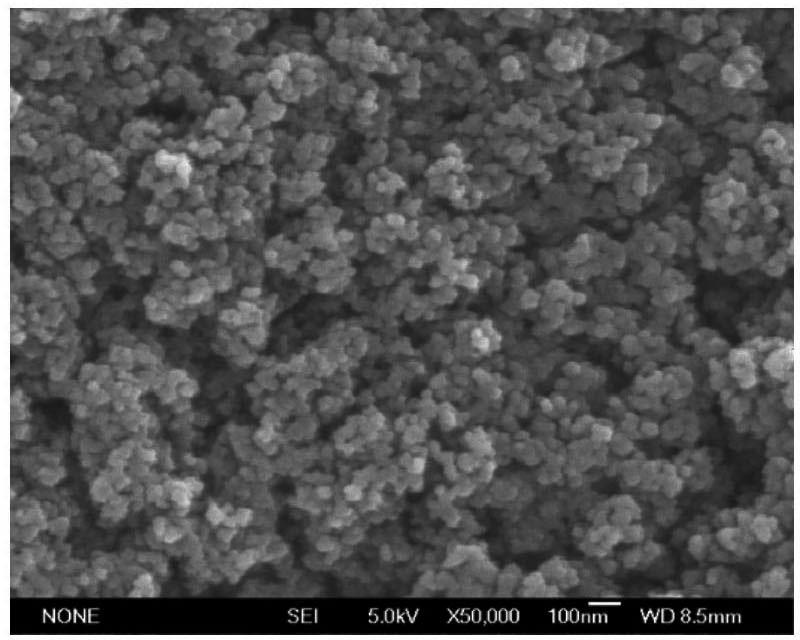

[0034] a kind of like figure 1 The imidized magnetic nano-adsorbent of the present invention shown, this adsorbent is formed by covalent cross-linking of magnetic nanoparticles and polyethyleneimine, the particle diameter of the adsorbent is 60nm, and the magnetic nanoparticles are made of nanometer tetroxide Tri-iron calcination is obtained, and the surface of magnetic nanoparticles is formed with γ-Fe 2 o 3 .

[0035] A preparation method of the above-mentioned adsorbent, comprising the following steps:

[0036] (1) Preparation of magnetic nanoparticles: 0.2mol of ferrous chloride and 0.4mol of ferric chloride were prepared into a 300mL mixed solution, and then filled with nitrogen for 15min to remove the oxygen in the solution. Under stirring, add 4 mol / L ammonia solution, adjust the pH to about 11, react for 40 minutes, collect magnetic nanoparticles (nano ferric oxide, particle size is 40nm) by centrifugation, wash repeatedly, vacuum dry and grin...

Example Embodiment

[0038] Example 2: Application of adsorbent to simultaneously adsorb zinc and lead in lead-zinc binary metal solution

[0039] Will contain equimolar lead nitrate and zinc nitrate (C Zn =C Pb =1mmol / L) binary heavy metal solutions were divided into four groups, and then four groups of EDTA with different concentrations (0.1mmol / L, 0.5mmol / L, 0.8mmol / L, 1mmol / L) were added to make each group of mixed solutions The molar concentration ratio of EDTA and lead-zinc metal ions≤0.5, then adjust the pH value of the mixed solution to 6, then add the adsorbent prepared in Example 1 respectively, so that its concentration in each mixed solution is controlled at 2g / L, react for 240min, and complete the adsorption.

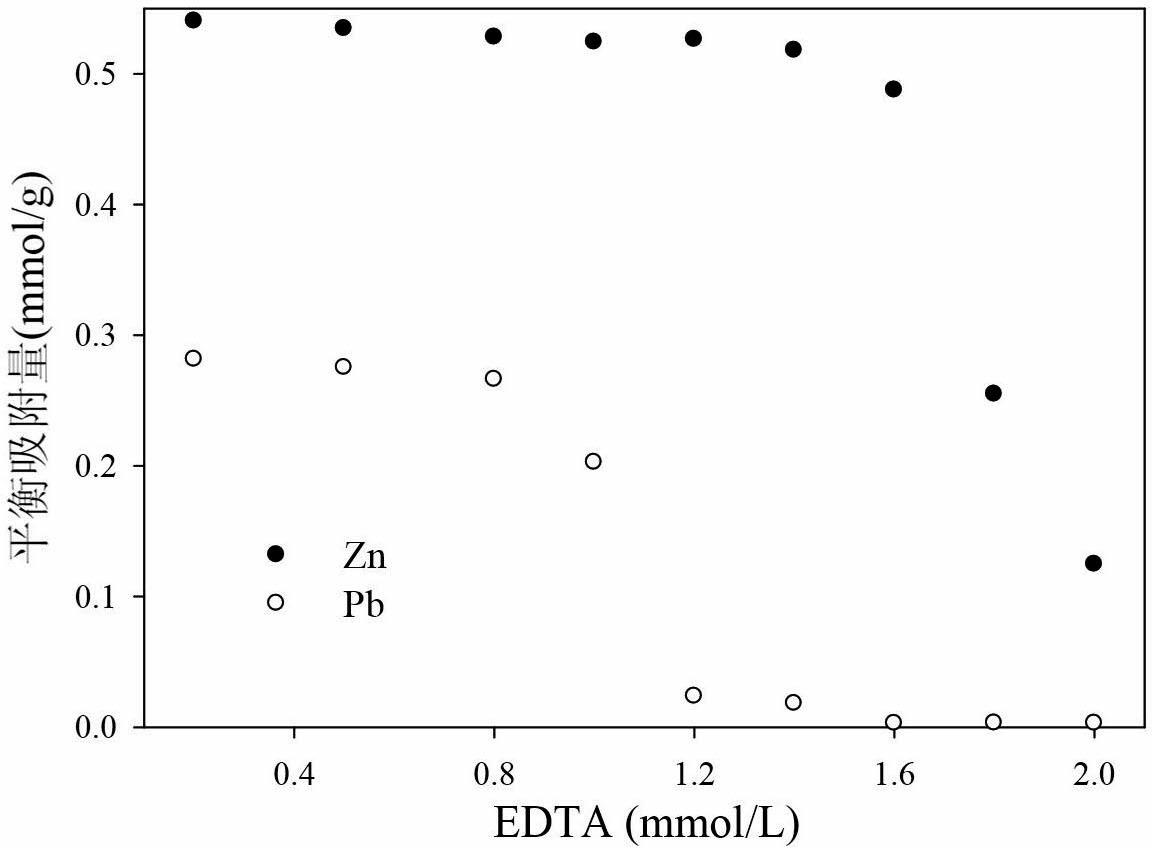

[0040] The result is as image 3 As shown, it can be seen from the figure that when the molar concentration ratio of EDTA to lead-zinc metal ions in the lead-zinc binary metal solution is ≤0.5, the adsorbent has a good adsorption effect on both zinc and lead in the lead-z...

Example Embodiment

[0041] Example 3: Application of adsorbent to selectively adsorb zinc in lead-zinc binary metal solution

[0042] (1) Under the conditions of different concentrations of EDTA

[0043] Will contain equimolar lead nitrate and zinc nitrate (C Zn =C Pb =1mmol / L) binary metal solutions were divided into five groups, and then five groups of EDTA with different concentrations (1.2mmol / L, 1.4mmol / L, 1.6mmol / L, 1.8mmol / L, 2.0mmol / L) were added respectively, Make the molar concentration ratio of EDTA and lead-zinc metal ions in each group of mixed solutions in the range of (0.6-1.0): 1, then adjust the pH value of the mixed solution to 6, and then add the adsorbent prepared in Example 1 respectively , so that its concentration in each group of mixed solutions is controlled at 2g / L, and the reaction takes 240min to complete the adsorption.

[0044] The result is as image 3 As shown, it can be seen from the figure that when the molar concentration ratio of EDTA to zinc and lead in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com