Motor, motor cooling system and electric vehicle

A coolant and end cap technology, applied in the field of electric vehicles, can solve the problems of high heat dissipation design cost and low reliability, and achieve the effects of low material management cost, high reliability, and improved work performance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

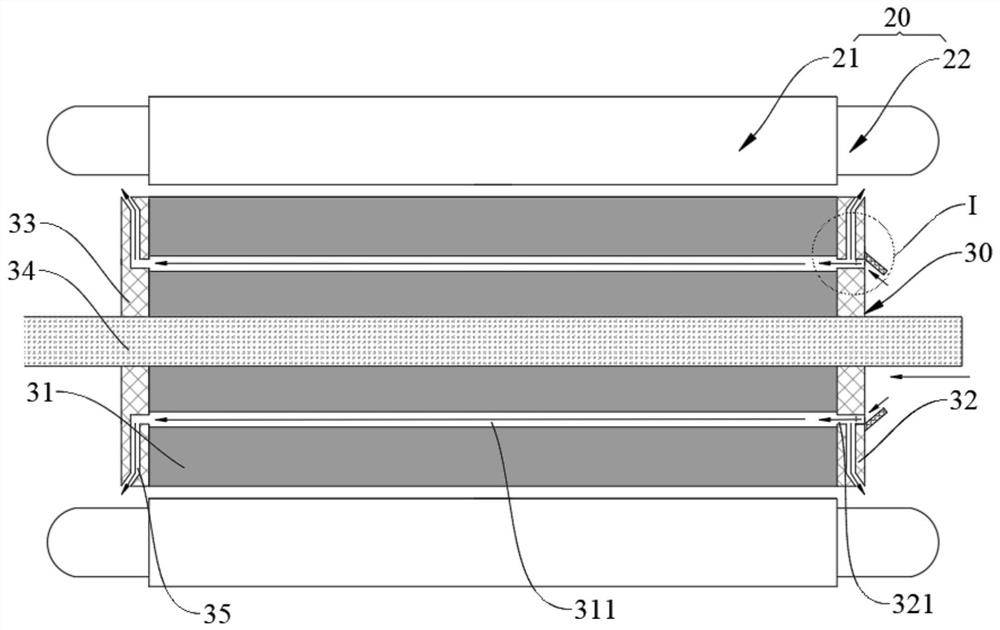

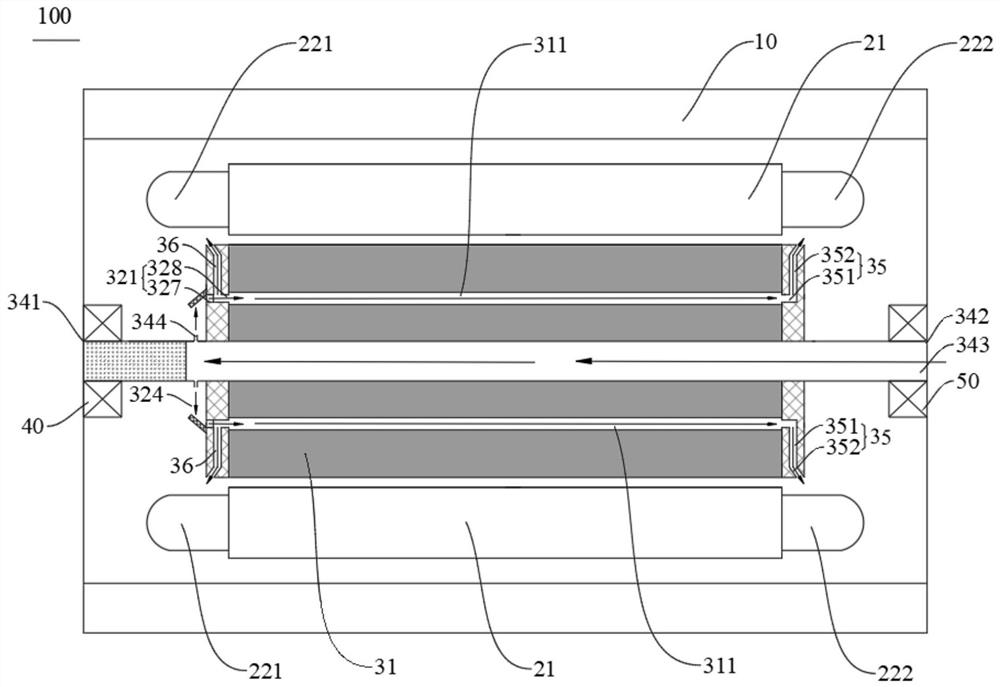

[0068] The specific implementation manners of the present application will be clearly described below in conjunction with the accompanying drawings.

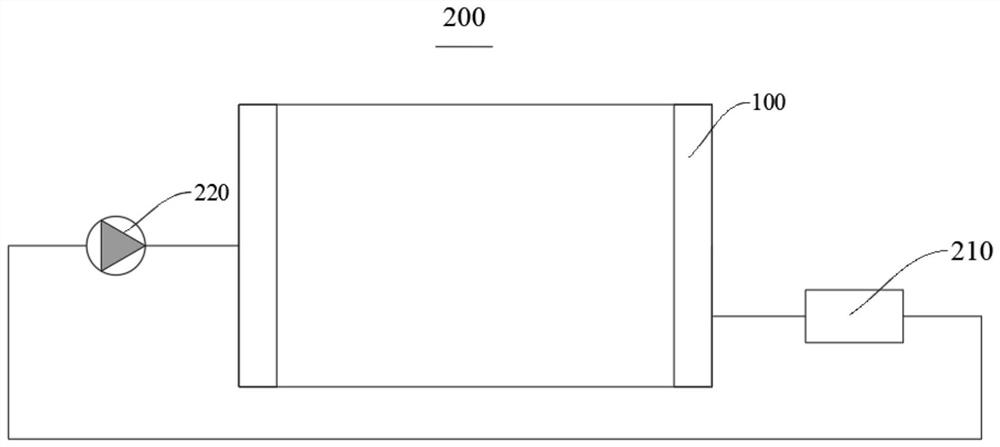

[0069] see figure 1 , the embodiment of the present application provides a motor cooling system 200 including the motor 100 , the motor cooling system 200 can be applied in a mechanical device to dissipate heat and cool the motor 100 . For example, the mechanical equipment may be any mechanical device such as electric vehicles, processing equipment, and engineering machinery.

[0070] Specifically, heat dissipation and cooling of the motor 100 can be achieved by providing a flow channel in the motor cooling system 200 and using coolant as a heat exchange medium to allow the coolant to flow in the flow channel to take away heat generated by the motor 100 . For example, the motor 100 may be, but not limited to, a permanent magnet synchronous motor, an asynchronous induction motor, or a generator. The coolant can be lubricating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com