Large-diameter steel pile casing and three-frame type guide frame driving construction method

A construction method and steel casing technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems such as difficulty in controlling the accuracy of steel casing drilling, low construction efficiency, and greater requirements for the hoisting height of door cranes. Achieve the effects of ensuring construction progress and quality, improving drilling accuracy, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

[0034] Referring to the accompanying drawings, it can be seen that the construction method of the large-diameter steel casing and the three-frame guide frame is characterized in that it includes the following steps:

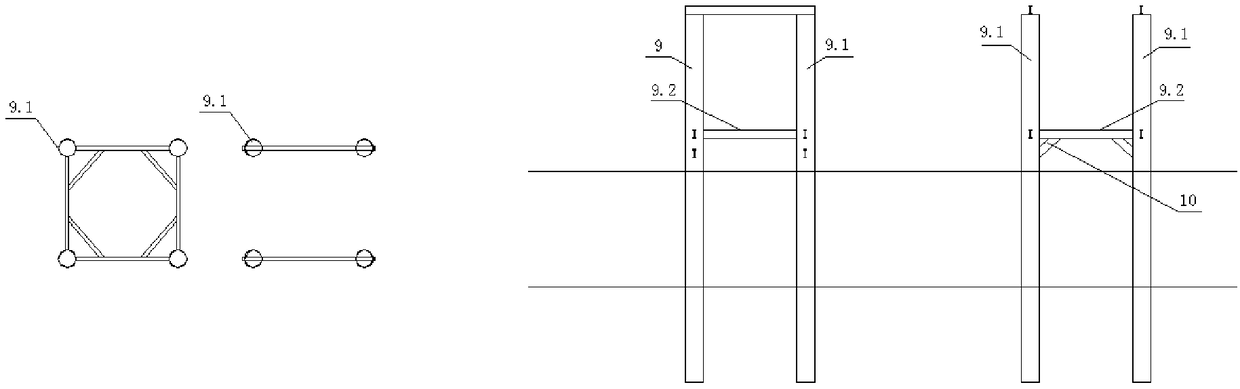

[0035] Step 1: Drive in four auxiliary piles 9.1, and the auxiliary piles 9.1 are connected with I-shaped steel to form the auxiliary pile superstructure and the auxiliary pile substructure, and the auxiliary pile superstructure and the auxiliary pile substructure constitute the auxiliary positioning steel pipe pile platform 9.2 (such as figure 1 shown);

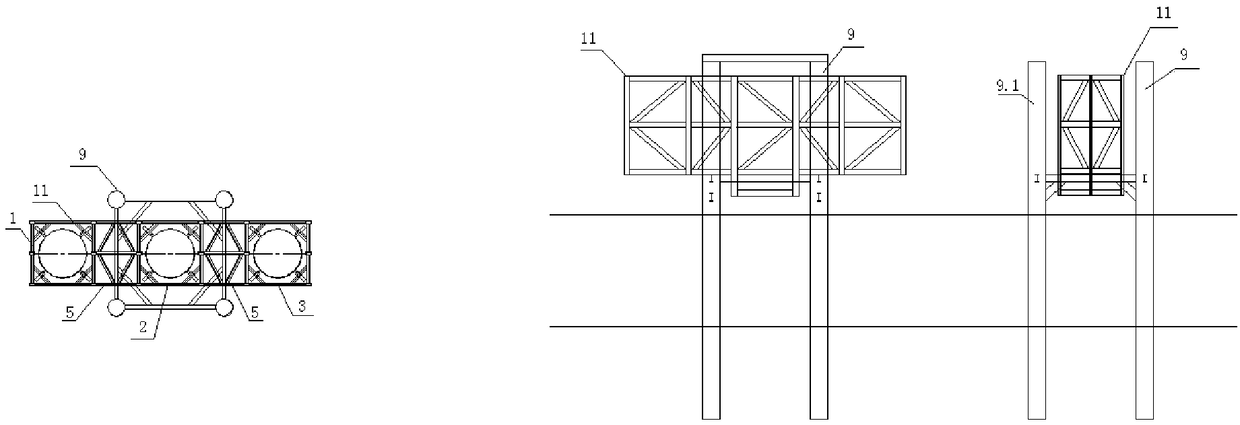

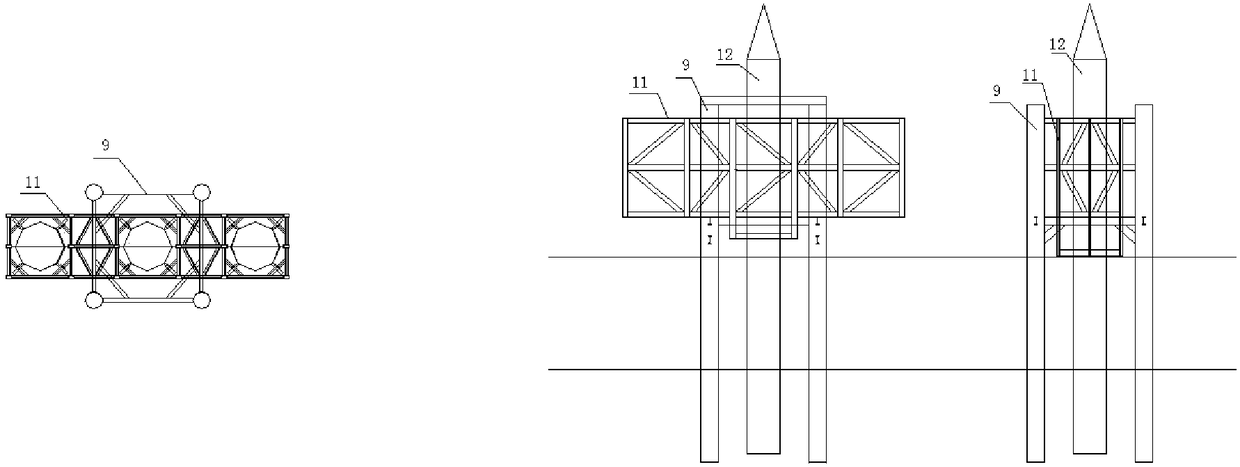

[0036] Step 2: Place the three-frame guide frame 11 on the auxiliary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com