Concrete floor slab descending area slab surface shaping support construction method

A construction method and concrete technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, climate change adaptation, etc. The effect of quick installation and disassembly, cost saving and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

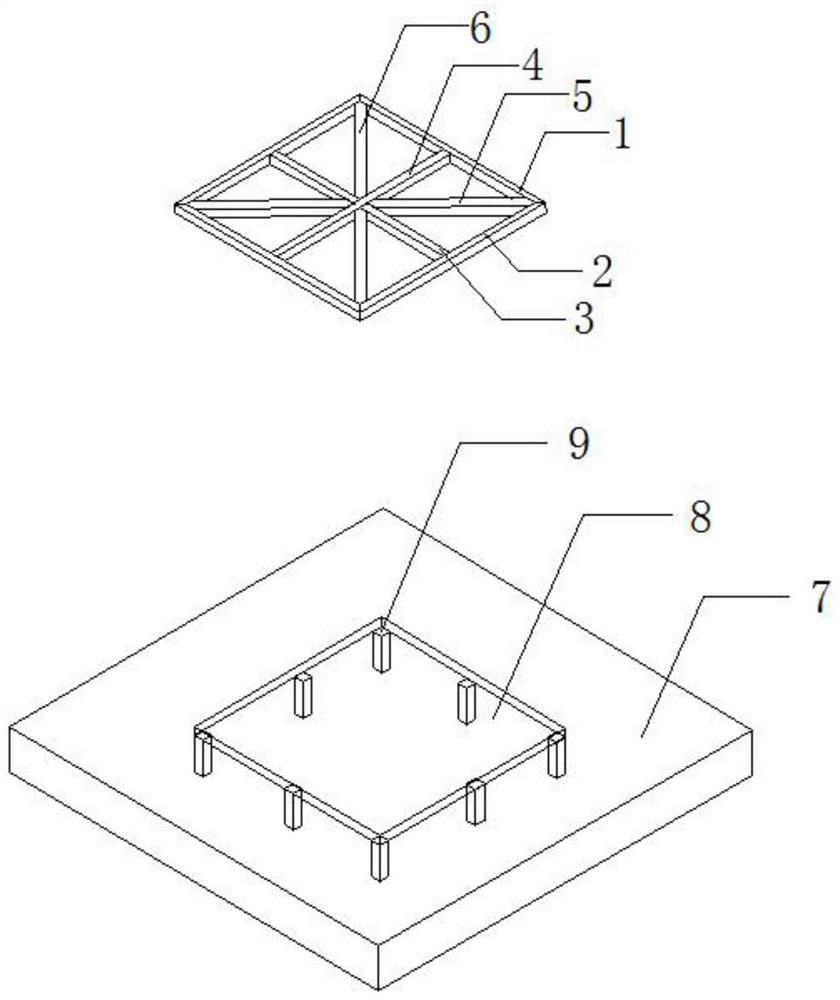

[0022] like figure 1 As shown in the figure, a construction method for shaping the slab surface in the descending area of the concrete floor slab in this embodiment includes the following steps:

[0023] Step 1: First make the crossbar 1 (requires the horizontal net dimension length of the crossbar 1 and the lowering area 8), then make the vertical bar 2 (requires the horizontal bar 2 and the vertical length of the lowering area 8 are the same), and Arrange the outer side of the horizontal rod 1 and the outer side of the longitudinal rod 2 according to the cross-sectional size of the upper and lower plate area 8 of the floor slab 7, and cut off the overlapping parts of the two ends and then weld and fix them;

[0024] Step 2: Next, make the inner longitudinal rod 4 (the length of the inner longitudinal rod 4 is required to be the length of the longitudinal rod 2 minus twice the width of the transverse rod 2), and place the inner longitudinal rod 4 in the center of the transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com