Cement concrete pavement slab edge concealed grouting and void risk evaluation method

A technology of cement concrete and risk assessment, which is applied in the field of airport engineering, can solve problems such as runway structural damage, achieve strong concealment, ensure construction quality, and accurately assess the risk of emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

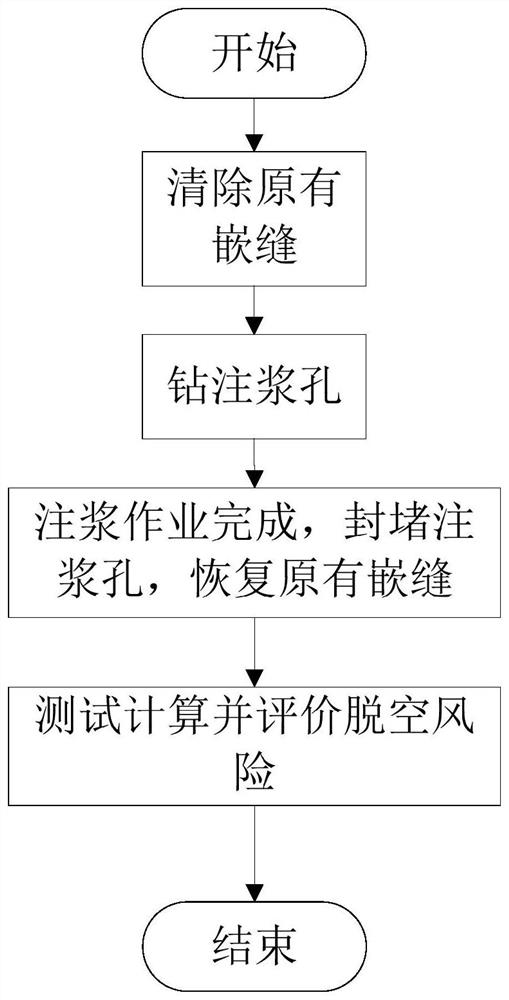

[0027] The concealed grouting at the edge of cement concrete pavement slab provided by the present invention and the evaluation method for void risk will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

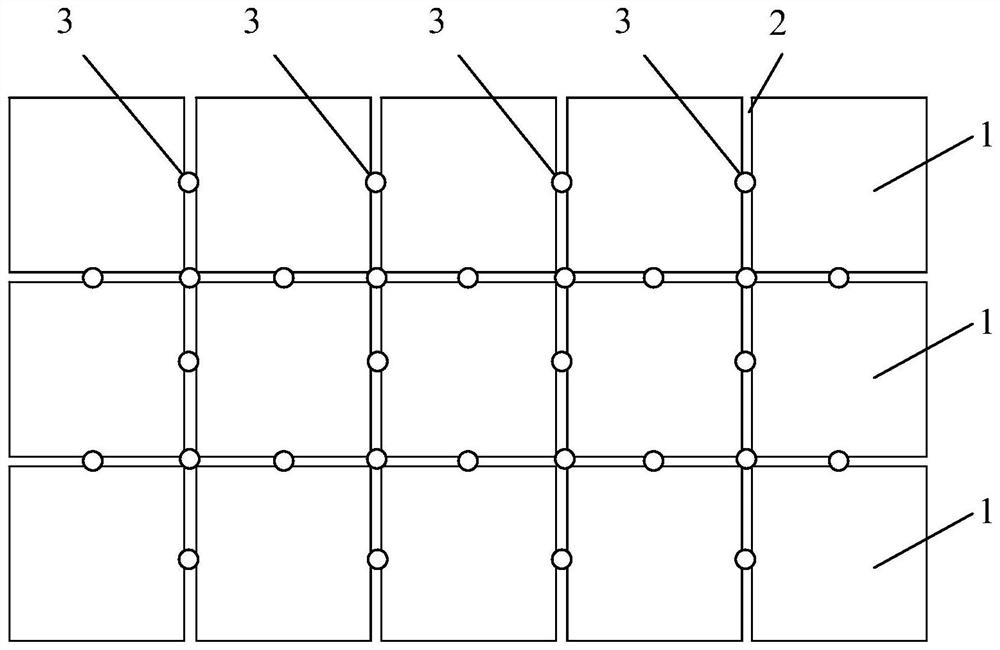

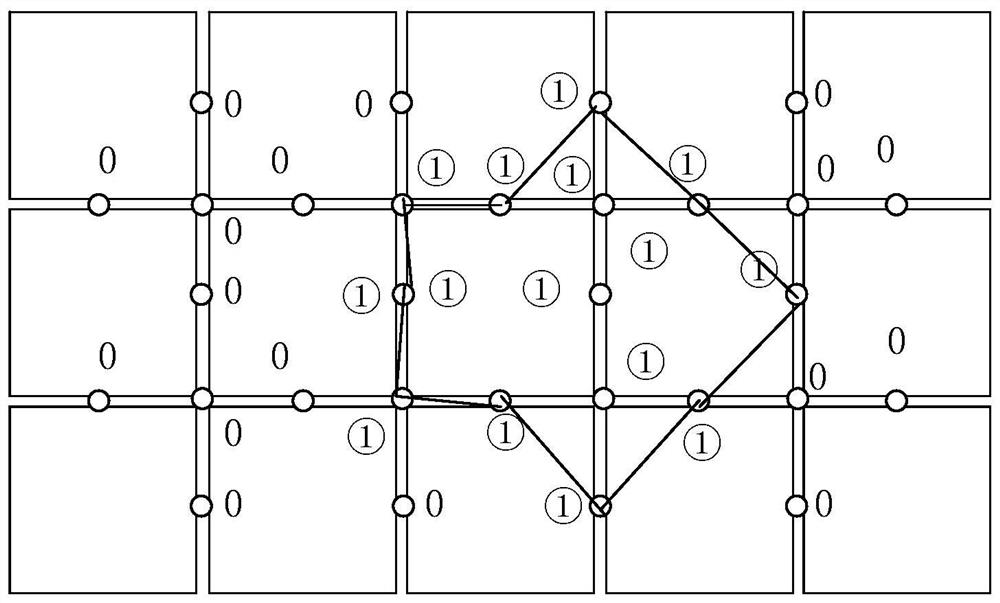

[0028] Such as figure 1 — image 3 As shown, the cement concrete pavement edge concealed grouting and emptying risk assessment method provided by the present invention is suitable for the preventive emptying treatment of pavements that have been used for 5-10 years, that is, multiple blocks are adjacent to each other The void of the panel 1 only exists at the edges and corners of the panel, and there is no void in the middle of the panel.

[0029] The concealed grouting and emptying risk assessment method for the cement concrete pavement slab edge provided by the present invention includes the following steps in order:

[0030] 1) Firstly, the construction personnel determine the grouting area, and then place the joints 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com