Modular integrally-assembled building system, building module units and connecting joints

A technology of modular units and connecting nodes, applied in the direction of buildings, building types, special buildings, etc., can solve the problems of building quality and high temperature, poor thermal insulation, poor sound insulation physical properties, low efficiency and waste in transportation, stacking, hoisting and turnover. Building materials and other issues, to achieve the effect of improving thermal insulation and space tightness, improving engineering quality and building quality, and improving integrity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

[0054] In the description of the present invention, it should be noted that the terms "A" and "B" are only used for descriptive purposes, and should not be understood as indicating or implying relative importance.

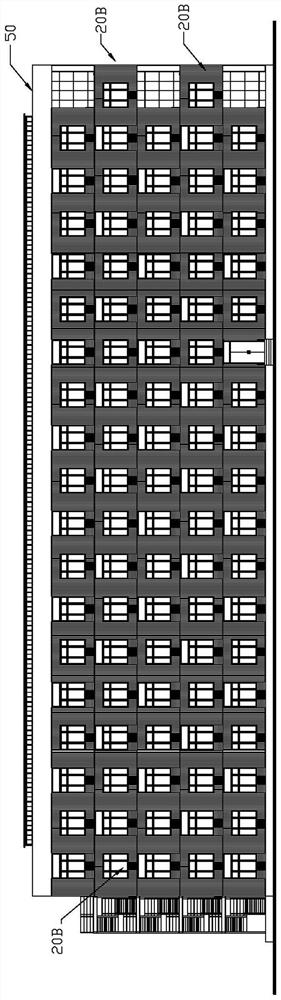

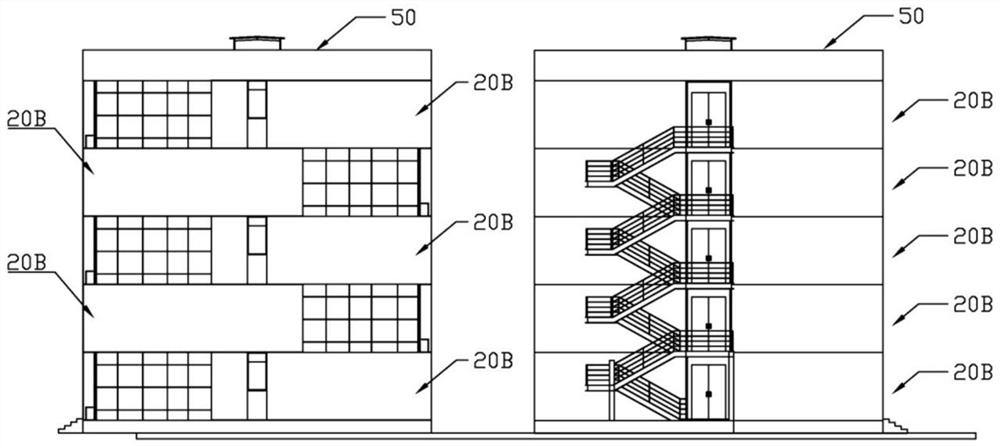

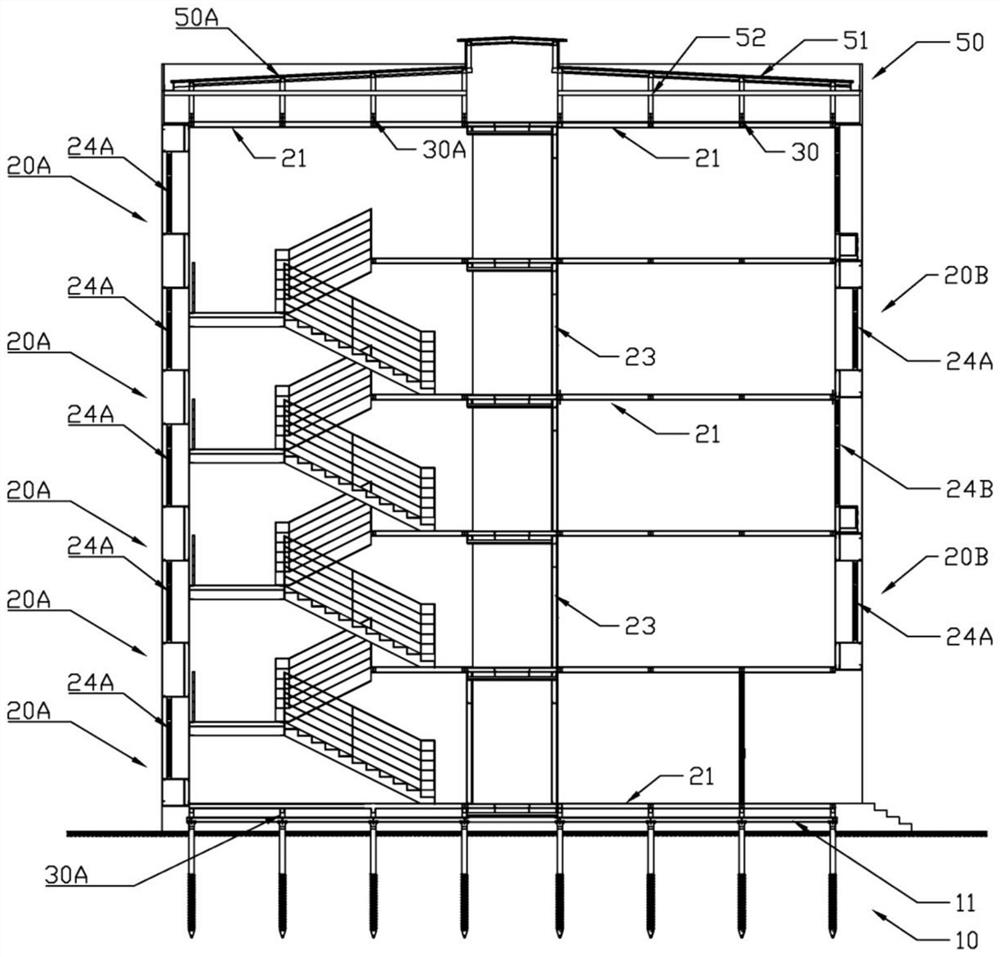

[0055] Such as Picture 1-1 and Figure 1-2 As shown, a modular prefabricated building system proposed by the present invention includes multi-layer building module units arranged above the foundation 10, and a roof 50 is provided on the topmost building module unit.

[0056] Such as figure 2 As shown, the foundation 10 is in the form of a pile foundation or a strip foundation, and a foundation beam 11 is fixed on the top of the foundation 10, and the foundation beam 11 is connected to the building module units on the first floor through a connection node A30A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com