Large bottom plate modular structure under time-limited condition and construction method

A modularized, bottom plate technology, applied in underwater structures, infrastructure engineering, artificial islands, etc., can solve the problems of high labor intensity, large impact on the surrounding environment of the project, long construction period, etc. The effect of the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

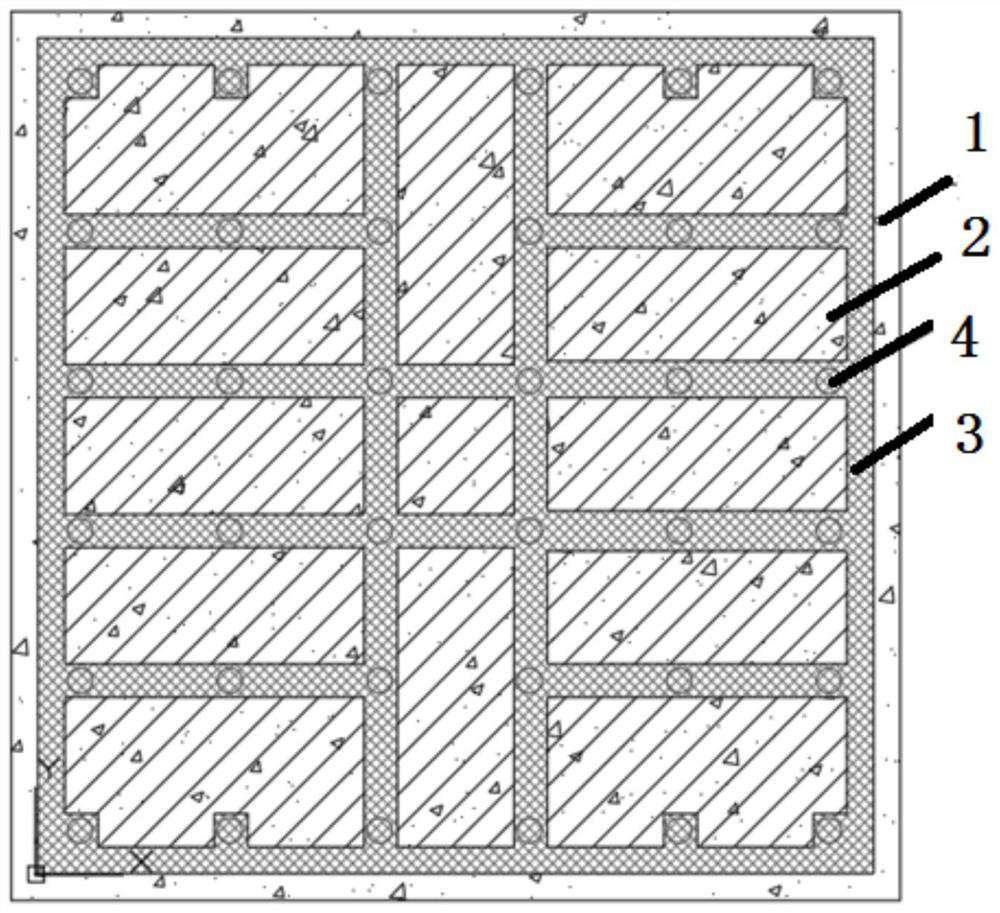

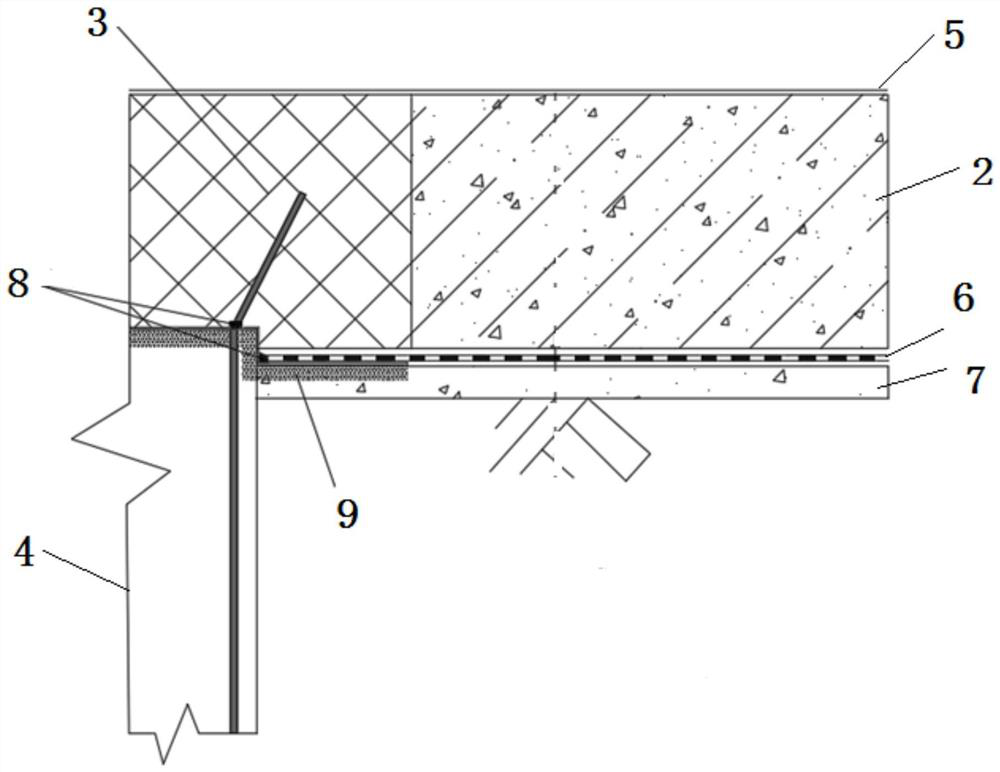

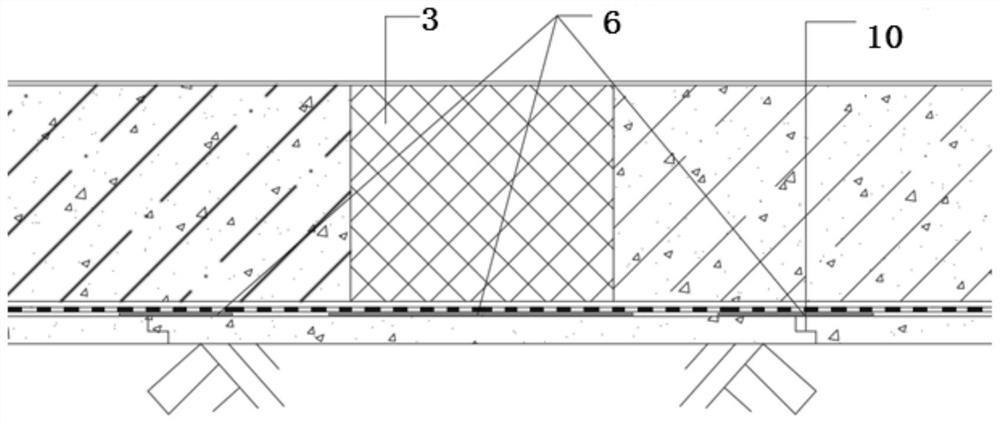

[0031] like Figures 1 to 3 As shown, the present invention provides a large base plate modular structure under time-limited conditions, including:

[0032] A plurality of prefabricated large base plates 2 arranged in the underground continuous wall 1;

[0033] The post-casting belt 3 is arranged between the prefabricated large base plates 2 of the adjacent blocks, and the overhanging steel bars of each prefabricated large base plate 2 extend into the post-casting belt 3, and the overhangs of the adjacent two prefabricated large base plates 2 extend into the post-casting belt 3. Rebars are connected to each other;

[0034] The pile body of the cast-in-place pile 4 arranged at the lower part of the post-casting zone 3, the rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com