Highly conductive substrate and manufacturing method thereof

A high-conductivity, manufacturing method technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve problems such as high equipment requirements, poor light transmittance of thin films, and inability to synthesize graphene. The effect of low impurity content, good electrical conductivity and light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

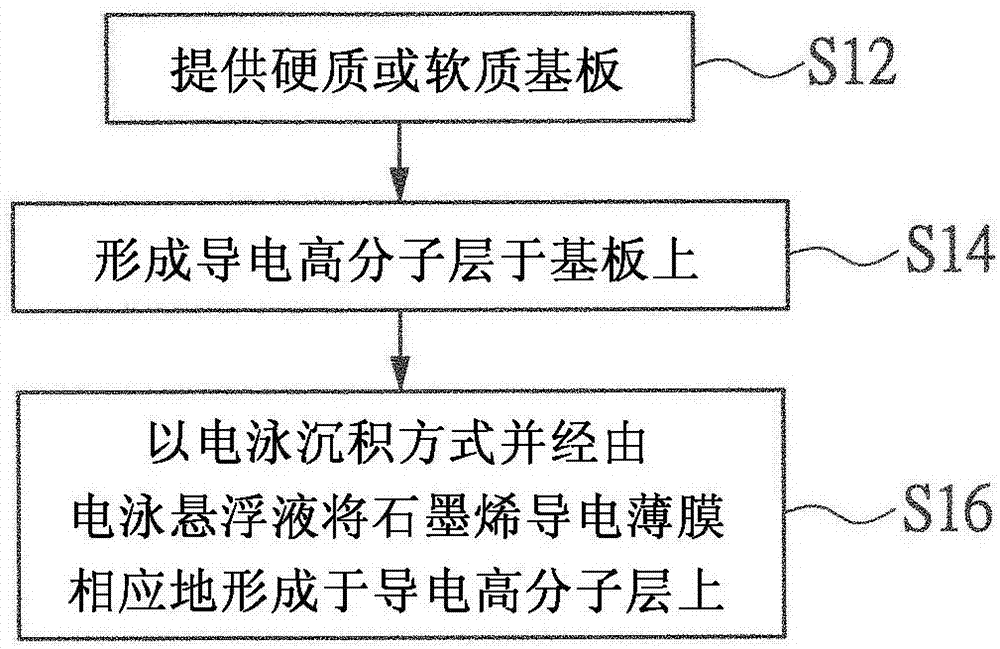

[0041] Please refer to figure 1 , is a schematic flow chart of the manufacturing method of the highly conductive substrate according to the first embodiment of the present invention. Please cooperate with reference Figures 2A to 4B , for the corresponding figure 1 Schematic diagram of the fabrication process for each fabrication process step. first as figure 1 As shown, the manufacturing method of the highly conductive substrate of this embodiment mainly includes: step S12, providing a hard or soft substrate; step S14, forming a conductive polymer layer on the substrate; and step S16, electrophoretic deposition and via The electrophoretic suspension forms the graphene conductive film on the conductive polymer layer accordingly.

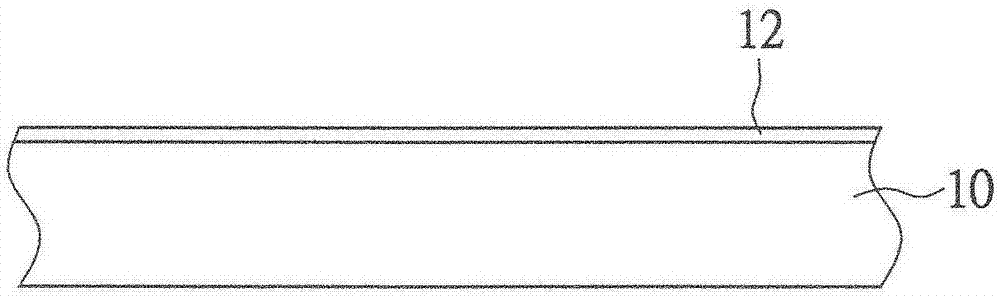

[0042] Please cooperate with reference Figure 2A and 2B , the manufacturing method of this embodiment first provides a hard or soft substrate 10 (step S12). In practical implementation, the hard substrate may be a metal substrate, a quartz su...

no. 2 example

[0050] Please refer to Figure 5 , is a schematic flow chart of the manufacturing method of the highly conductive substrate according to the second embodiment of the present invention. Please cooperate with reference Figures 6A to 7B , for the corresponding Figure 5 Schematic diagram of the fabrication process for each fabrication process step. first as Figure 5 As shown, the manufacturing method of the highly conductive substrate of this embodiment mainly includes: step S22, providing a hard or soft substrate; step S24, forming a conductive polymer layer on the substrate; step S26, patterning the conductive polymer layer; And step S28 , correspondingly forming the graphene conductive film on the patterned conductive polymer layer by means of electrophoretic deposition and via the electrophoretic suspension.

[0051] Please cooperate with reference Figures 6A to 7B The manufacturing method of this embodiment firstly provides a hard or soft substrate 10 (step S22 ). Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com