Modular assembly type pile foundation wharf structure system and construction method thereof

A modular and prefabricated technology, applied in the field of ports and wharfs, can solve the problems of short effective construction time, low construction efficiency, long construction period, etc., to avoid special dangerous construction procedures, reduce labor costs, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

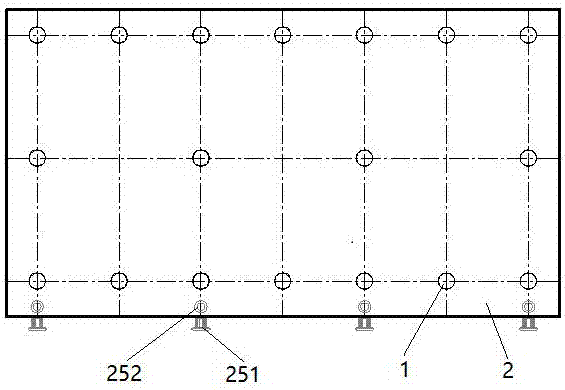

[0057] Such as Figure 1-6 As mentioned, a modular assembly type pile foundation wharf structure system includes:

[0058] Pile foundation (1), modular superstructure (2), connection node between pile foundation and modular superstructure (3);

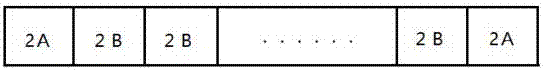

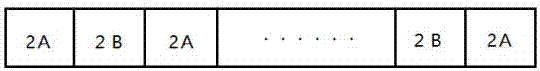

[0059] The overall plane size of the berths of the bulk cargo terminal is 1400 (length) * 30 (width) m, and its superstructure (2) is divided into 28 parts, which are first manufactured and processed in the factory, and then transported to the site by waterway, and then assembled and installed in place , including 14 first modular superstructure parts (2A) and 14 second modular superstructure parts (2B), each with a plane dimension of 50 (length) * 30 (width) m.

[0060] The pile foundation (1) of the modular assembly type pile foundation wharf structure system adopts straight pile steel pipe piles, which is convenient for the overall installation and construction of the superstructure part (2). In this embodiment, the first and seco...

Embodiment 2

[0069] Such as Figure 1-6 As shown, the construction method of the modularized prefabricated pile foundation wharf structure system described in embodiment 1:

[0070] a. Complete the fabrication and processing of the steel structure of the modular superstructure (2) in the prefabrication plant. At the same time, dispatch the piling ship to the project site in time to carry out pile sinking construction.

[0071] b. After the piling ship arrives at the project site, carry out pile sinking construction of the pile foundation of the wharf, and timely monitor the deviation of the pile sinking, and form the on-site pile position map of the modular superstructure part (2), and timely feed back to the modular superstructure Part (2) of the prefabrication processing department; when necessary, consideration should be given to erecting pile foundation enclosures to ensure the stability of the pile foundation deviation.

[0072] c. Complete the welding and fixing of the lower protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com