Reinforcing steel bar fixing device

A technology of fixers and steel bars, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of easy adsorption of water vapor, loss of strength, and inability to guarantee the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

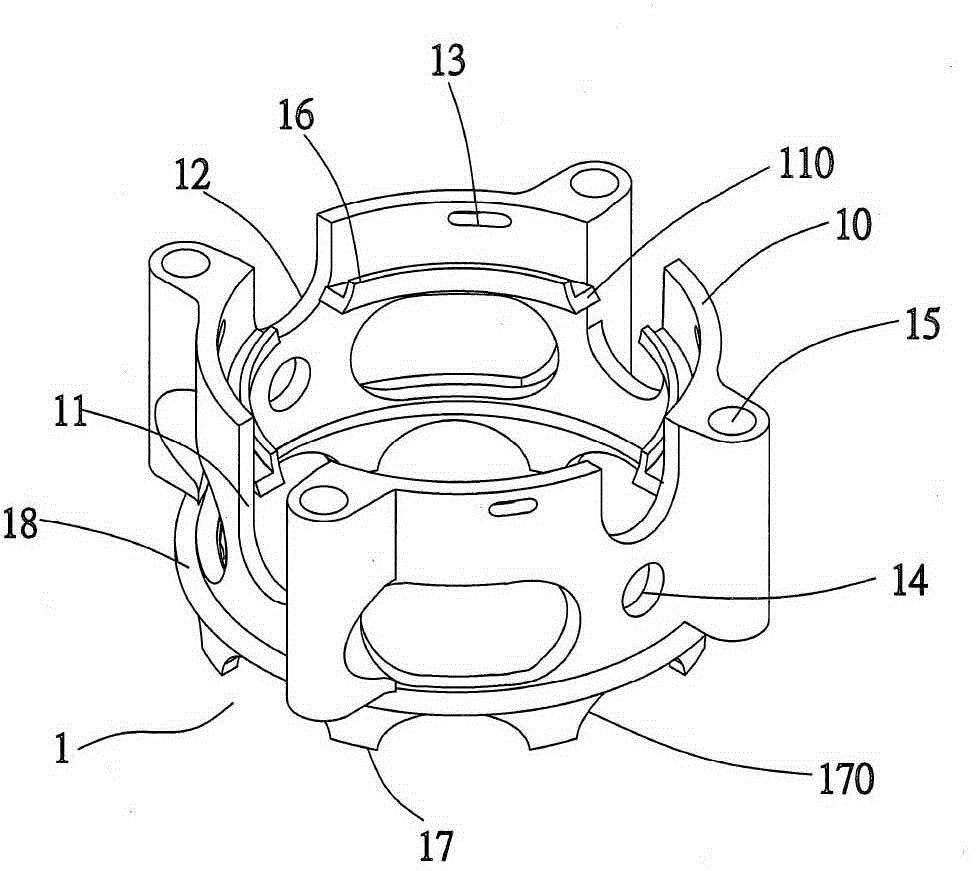

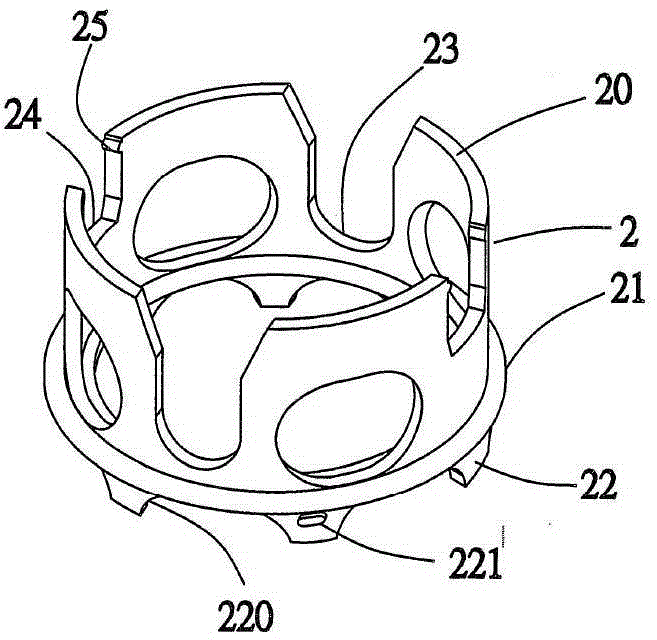

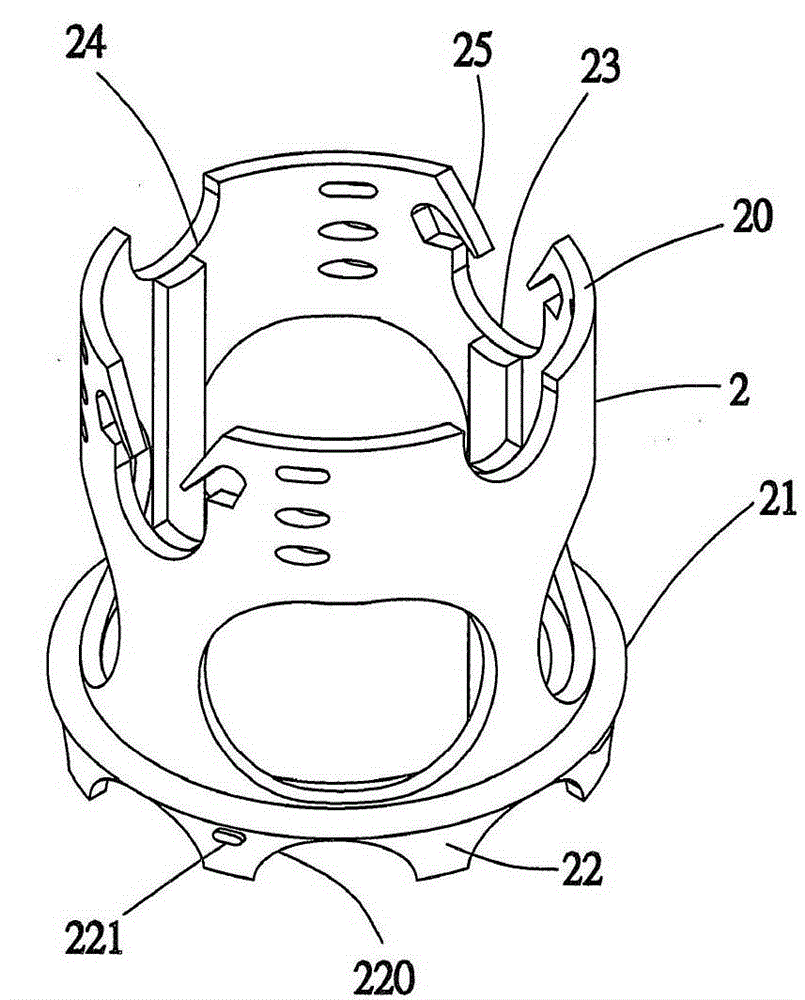

[0043] see Figure 1 to Figure 2C As shown, it is a schematic diagram of the structure of the base and the extension base of the steel bar fixer. The present invention can be combined and changed according to the requirements of single-layer or multi-layer steel bars. For the purpose of offset, moisture resistance and corrosion resistance, it mainly uses a light-weight and multi-functional base 1 as the basis to implement reinforcement weaving, and it can be combined with a group of extended bases 2 to form multi-layer reinforcement weaving according to height requirements. The content is detailed as follows:

[0044]The base 1 is a hollow cylinder with a porous surface, and the upper part is an upper bearing end 10. The upper bearing end 10 is respectively provided with a pair of deep grooves 11 and a pair of shallow grooves 12 in the axial direction on the end edge. The width of the deep groove 11 and the pair of shallow grooves 12 is at least the size of a steel bar diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com