Assembly for transporting windmill generator vane

A technology of wind turbines and blades, which is applied in the direction of wind turbine transportation, wind turbines, wind power generation, etc. It can solve the problems of energy consumption, high transportation costs, and the use of dozens or even hundreds of large vehicles, so as to improve competitiveness and reduce The effect of reducing manufacturing costs and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

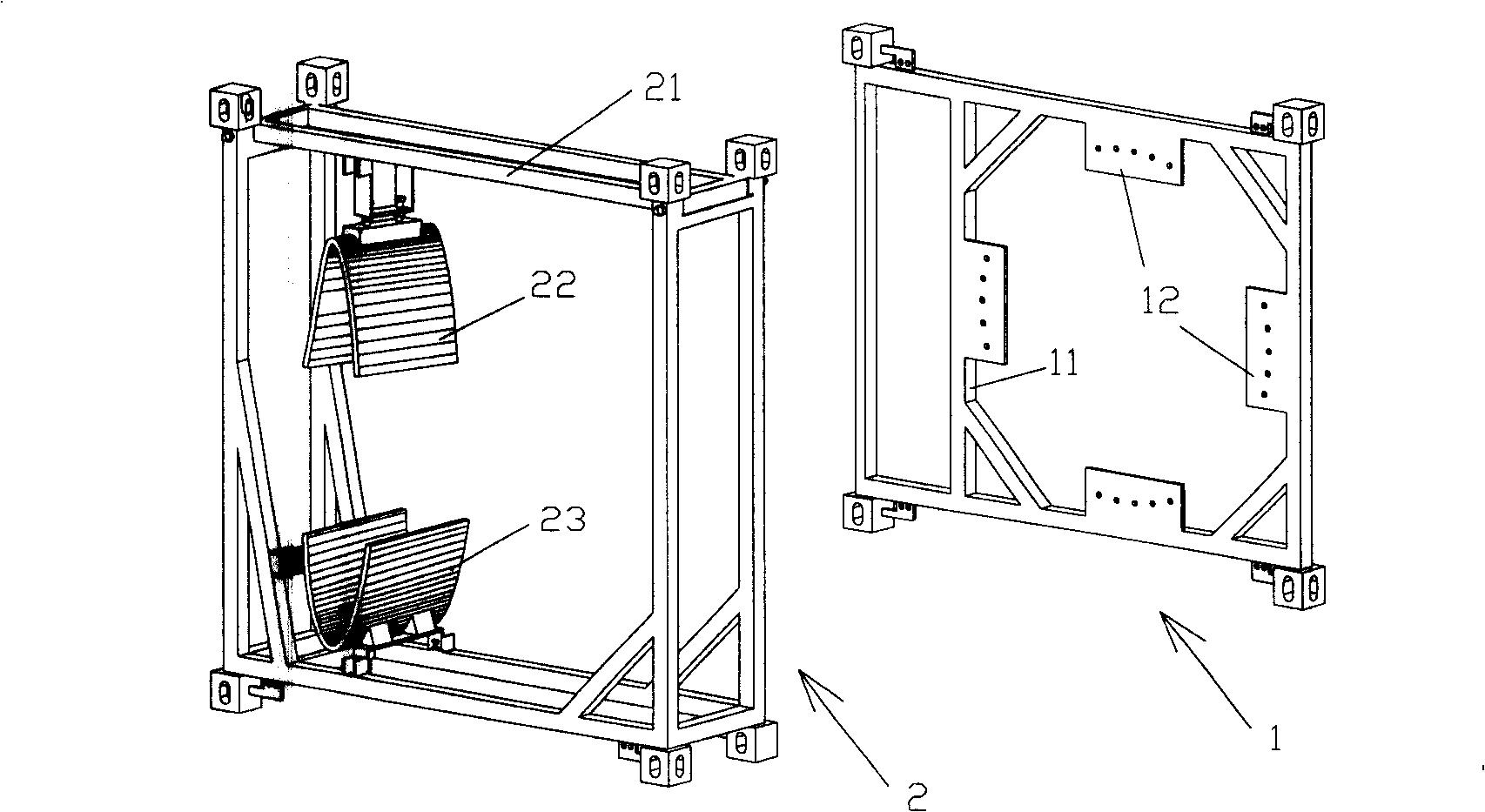

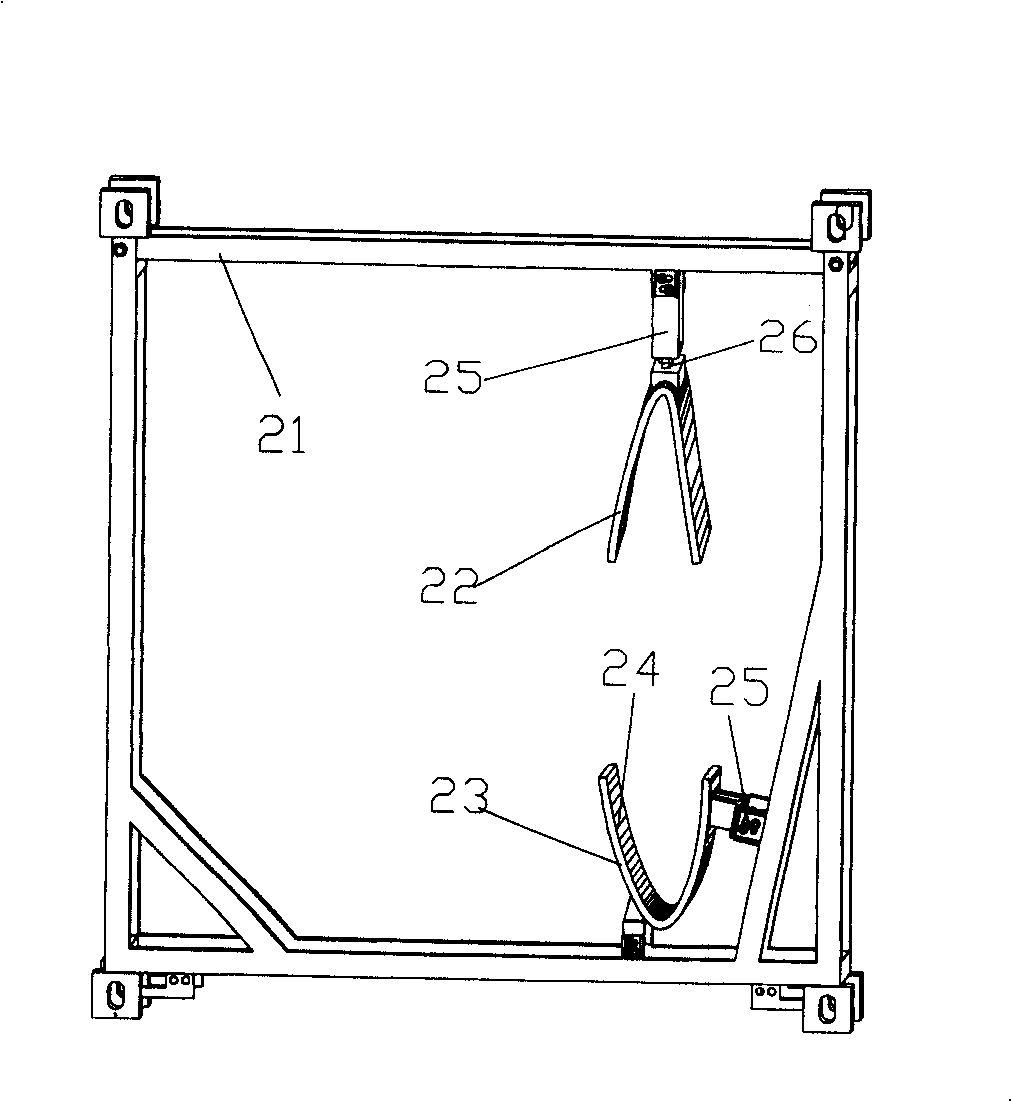

[0018] like Figure 1 to Figure 3 As shown, a tooling for transporting blades of a wind power generator, which includes two groups of tooling shown in the front and back, each group of tooling includes a blade root fixing frame 1 and a blade supporting frame 2;

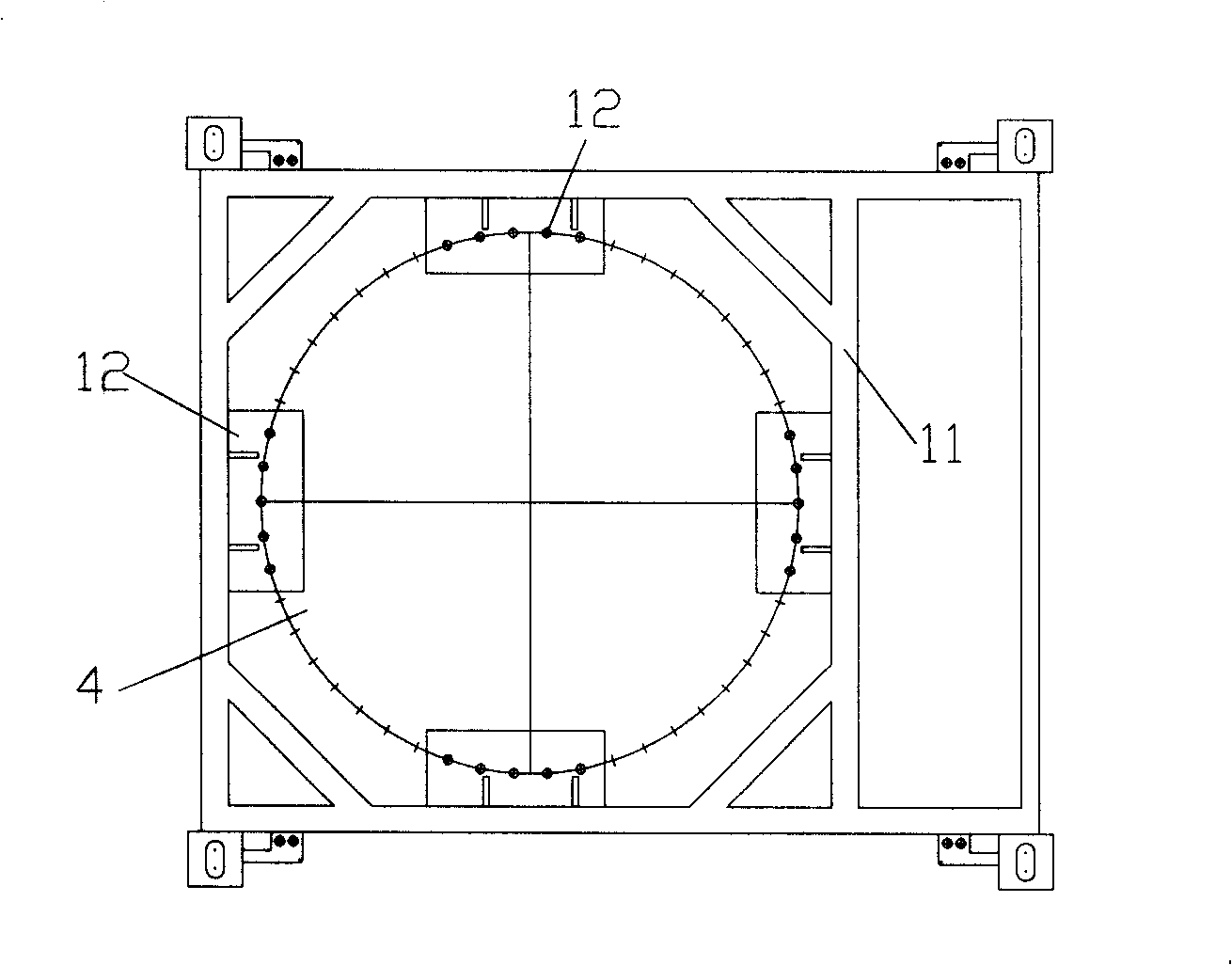

[0019] The blade root fixing bracket 1 is a rectangular frame structure, and a dividing link 11 is vertically arranged between the upper and lower poles to divide the blade root fixing bracket 1 into two large and small rectangular areas, wherein: the small rectangular area is the blade's The clamping area of the front wing, and the large rectangular area is the blade root connection area, the blade root can be accommodated between its four sides, and the four sides of the struts are also provided with bolts that can be engaged with the bolts 3 on the end of the blade root The blade root connection block 12 of the hole; the blade root connection area of the blade root fixing bracket 1 is provided with a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com