Indoor wall tile dry hanging assembly and application method thereof

An inner wall and tile technology, applied in the field of building decoration, can solve the problems of falling off, low work efficiency and high cost, and achieve the effects of easy installation and adjustment, high installation efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

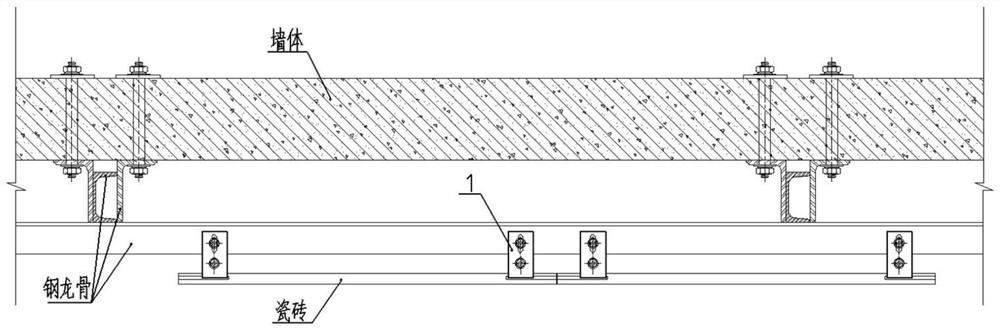

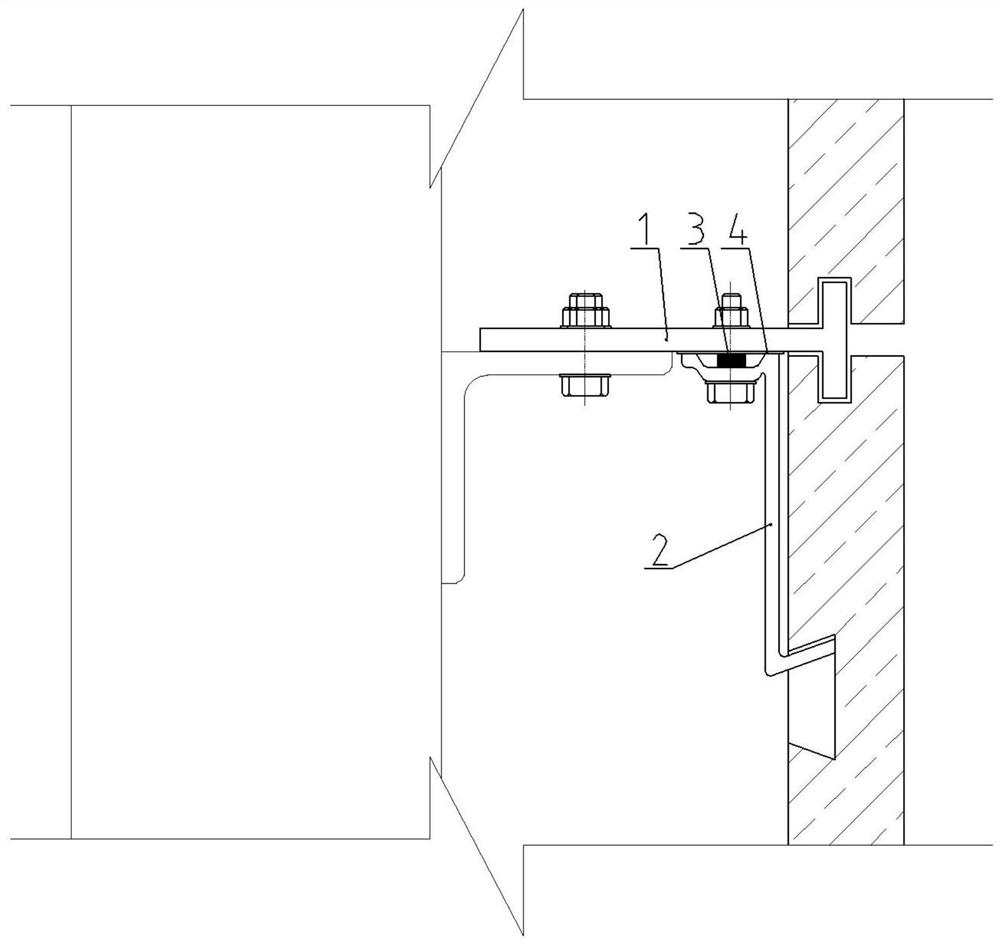

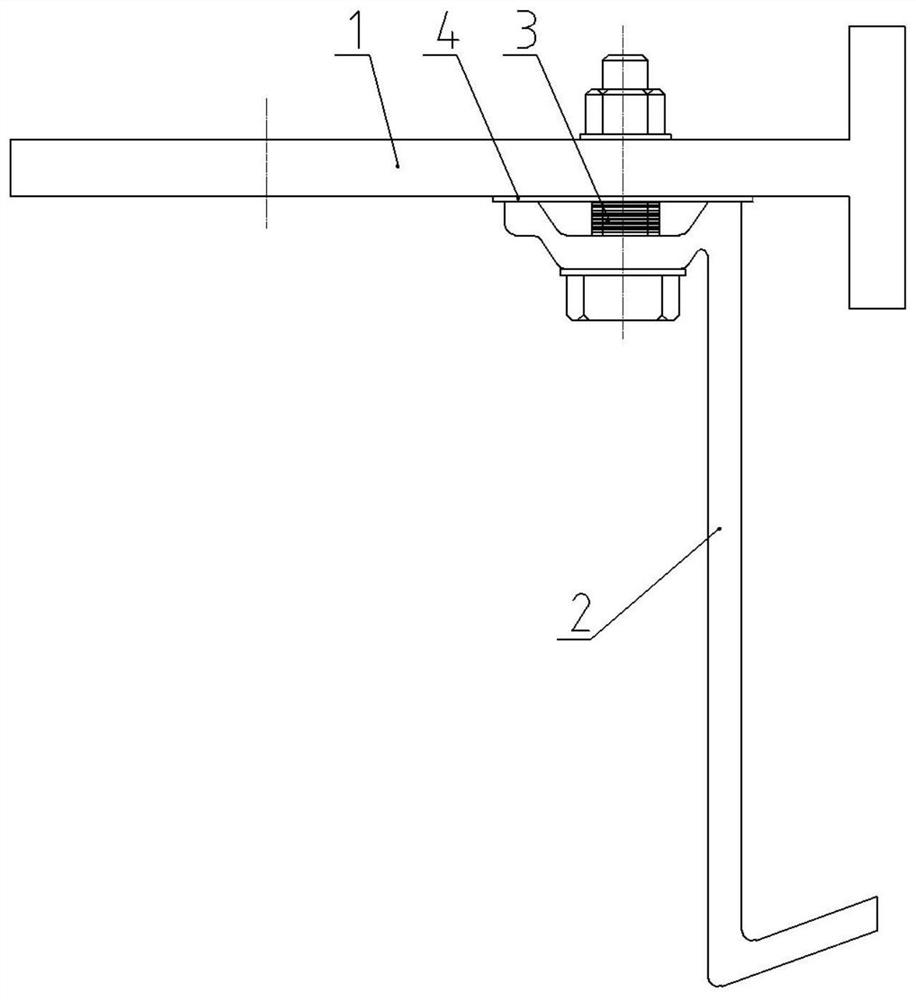

[0032] combine Figure 1 to Figure 4 It can be seen that the indoor wall tile dry-hanging assembly disclosed in this embodiment includes a T-shaped plate 1 , a vertical hanging 2 , a spring 3 , and a rubber pad 4 .

[0033] Horizontal inverted T-shaped plate 1 horizontal connector, its wing plate is used as the connection structure with the ceramic tile, and the horizontal plate is used as the connection structure of the angle steel of the steel keel of the vertical pendant.

[0034] There is an oblong hole and a round hole on the horizontal plate of the T-shaped plate part 1. The oblong hole is the installation hole for connecting the fastener between the horizontal plate and the angle steel of the steel keel, and the round hole is between the horizontal plate and the vertical hanging piece. Mounting holes for fasteners.

[0035] The vertical hanger 2 includes a vertical plate and a hook on one side of its lower end, and a connector on the other side of the upper end. The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com