Cable fixing device

A fixing device and cable technology, applied in the direction of electrical components, etc., can solve the problems affecting the safety and reliability of wind power generation, conductor exposure, leakage, etc., and achieve the effects of avoiding leakage and fire, fixing firmly, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

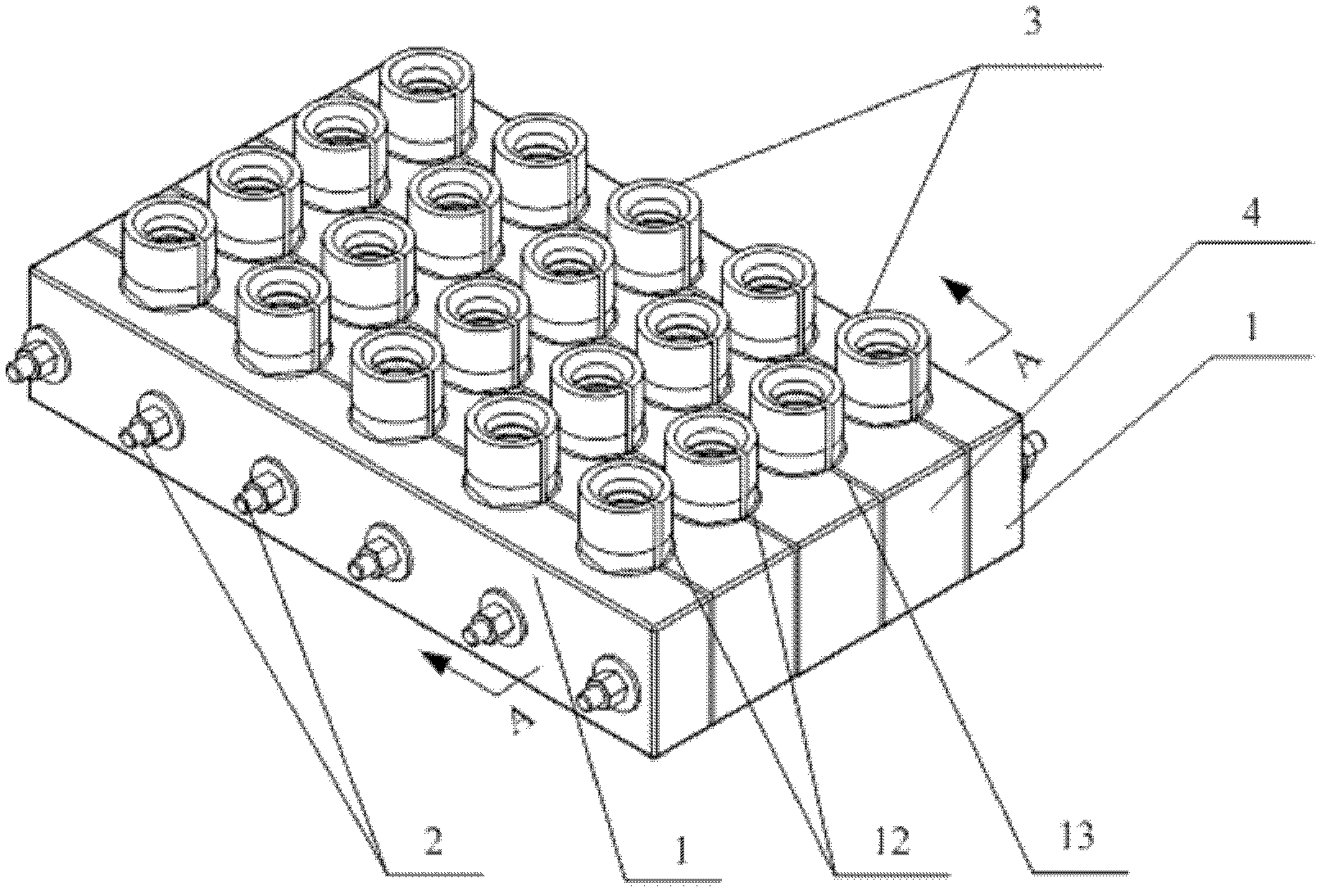

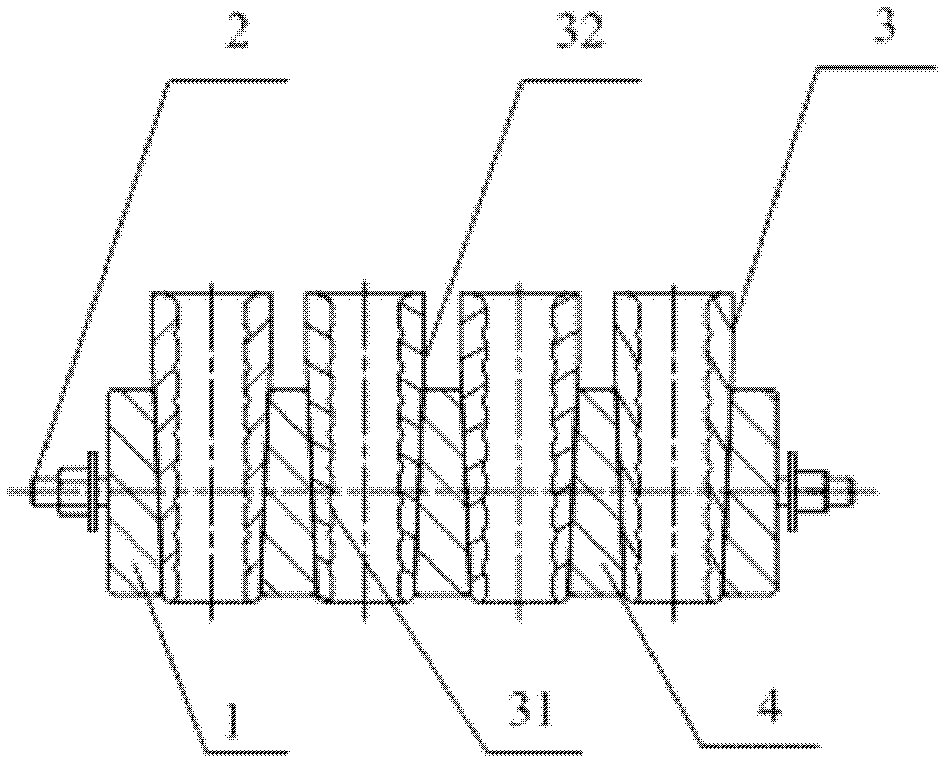

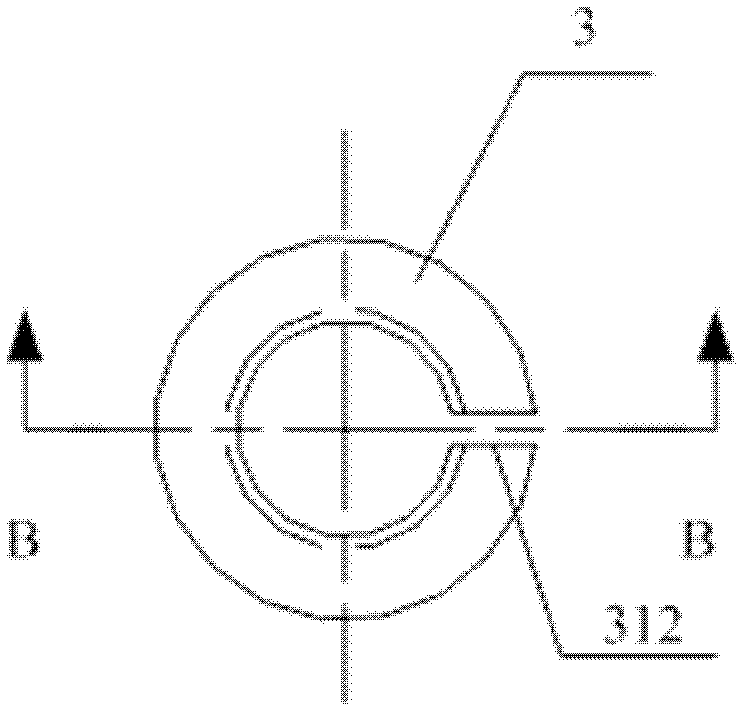

[0021] figure 1 It is the overall structure diagram of the embodiment of the cable fixing device of the present invention. figure 2 yes figure 1 A-A to the sectional view. Figure 5 yes figure 1 Top view of the mid-rim body and middle body. Please refer to figure 1 , figure 2 and Figure 5 , the cable fixing device provided in this embodiment includes two edge clips 1, each edge clip 1 is provided with at least one groove on one side, and the two opposite grooves on the two edge clips 1 11 forms a through hole 12, and the elastic sleeves 3 respectively pierced through the through holes 12 form a gap 13 between the edge clips 1, and a cable is respectively threaded in the elastic sleeve 3 with an interference fit; the bolt 2 penetrates the edge clip The body 1 clamps the elastic sleeve 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com