Assembled support post embedded component and embedding assembly construction method thereof

A hanger and assembly technology, which is applied in the pre-embedded components of the assembly-type hanger and its pre-embedded installation construction, can solve the problems of support types, specifications and types, poor quality control, and failure to achieve unity. Achieve the effect of improving the fixing effect, overcoming the low degree of standard, and realizing dust-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

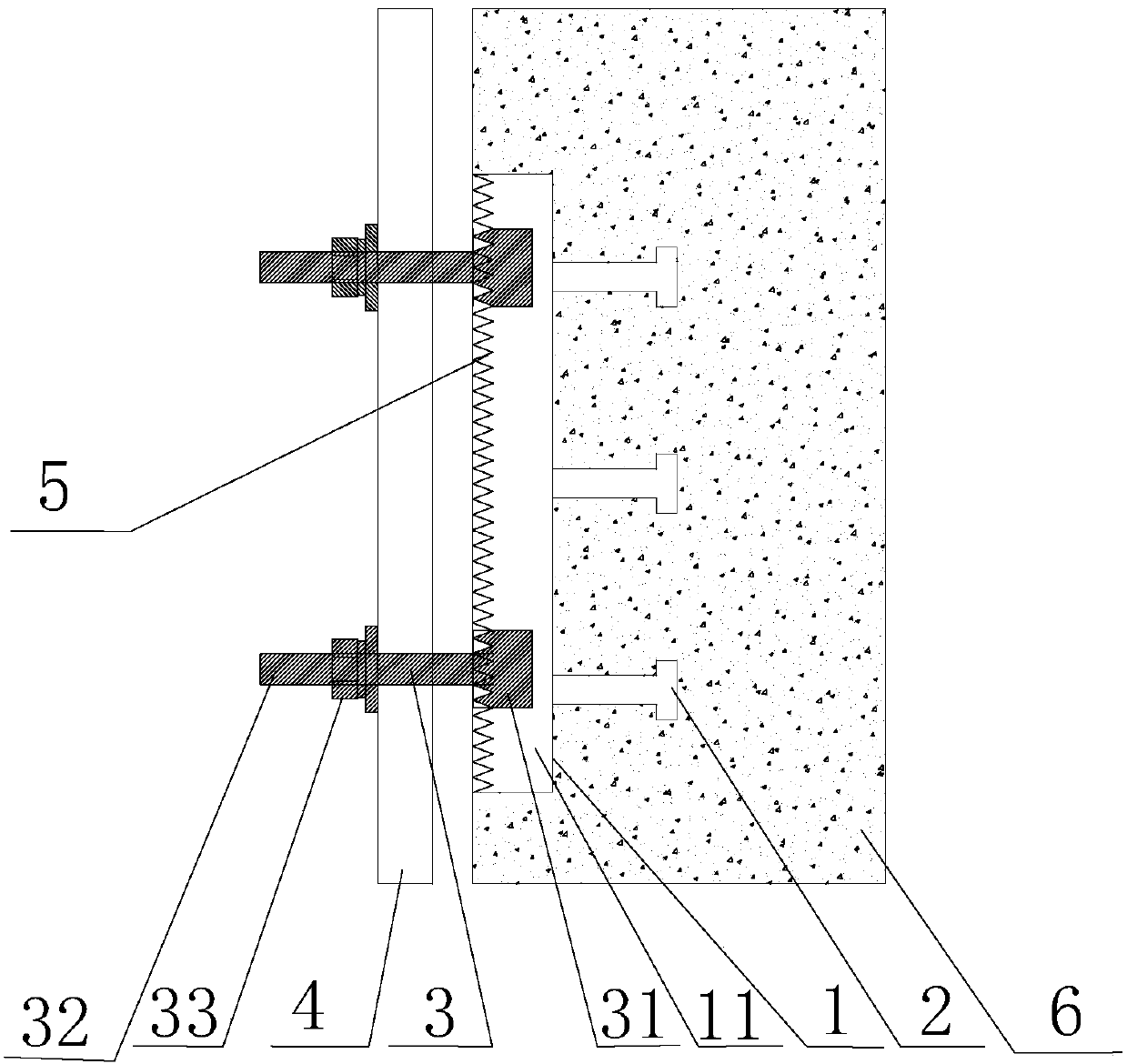

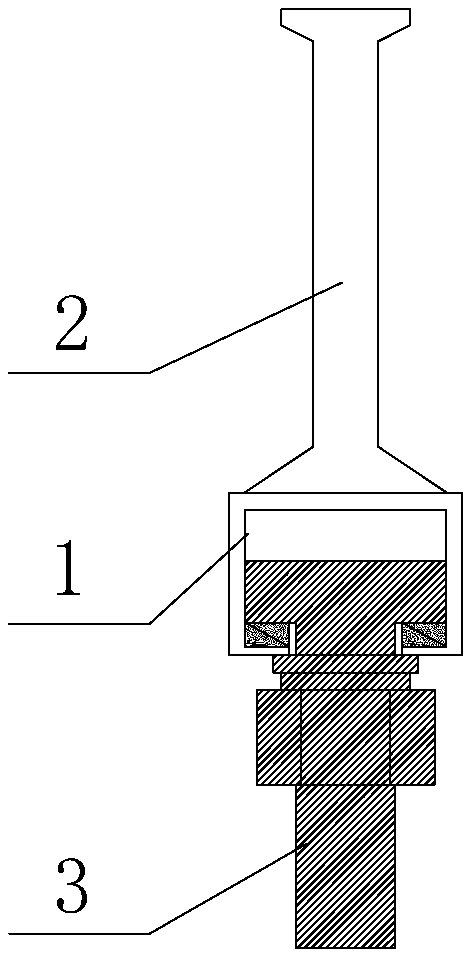

[0026] Embodiment 1: A pre-embedded component of a prefabricated support and hanger, including a pre-embedded channel steel 1, the back of the pre-embedded channel steel has an anchor bolt 2, and a T-shaped bolt 3 is installed at the notch of the pre-embedded channel steel 1 , and the bolt cap 31 of the T-bolt 3 is put into the notch of the embedded channel steel 1, the threaded end 32 of the T-bolt 3 faces outward, and also includes the embedded fixing part 4, the embedded fixing part 4 can be used in this device The grouting aluminum formwork is realized, and the installation hole matching the outer diameter of the T-bolt 3 is opened on the grouting aluminum formwork, and the threaded end 32 of the T-bolt 3 passes through the installation hole and is fixed by a nut 33; the embedded channel steel 1 After the T-bolt 3 is installed, the two ends are provided with sealing end covers, the hollow part of which is filled with foam 11, and the opening is sealed by a sealing film; the...

Embodiment 2

[0034] Embodiment 2: The structure and pre-embedded construction method in this embodiment are basically the same as those in Embodiment 1. The difference lies in that the clamping structure 5 is to alternately set obliques with different orientations on the contact surface between the pre-embedded channel steel and the bolt cap. Rack and rack, the contact surface of the bolt cap and the embedded channel steel is provided with a helical rack, and the bolt cap and the embedded channel steel alternately engage in the same direction. Different occlusal directions make the structure loosen in one direction and tighter in the other direction when the structure is subjected to external force, minimizing the impact of external force.

[0035] The adoption of this structure and construction method can overcome the problems of low standardization, poor quality control, poor verticality, low survival rate, and poor fit in the installation process of embedded parts in the prior art, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com