Standard modular components for buildings and prefabricated building comprising same

A standard module and construction technology, which is applied in the direction of construction and building construction, can solve the problems of prefabricated structures such as heavy weight, difficult quality control, and many connection points, so as to improve the efficiency of on-site installation, shorten development time, and reduce design costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 Standard Modular Assemblies for Construction

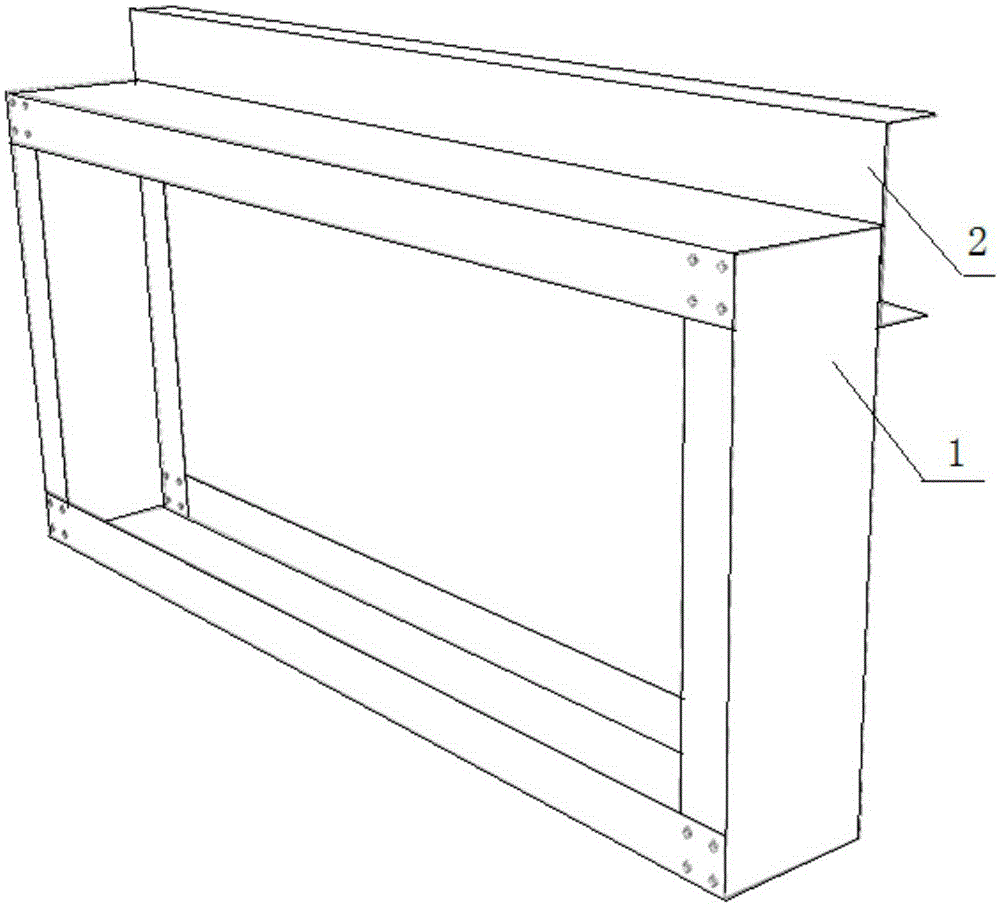

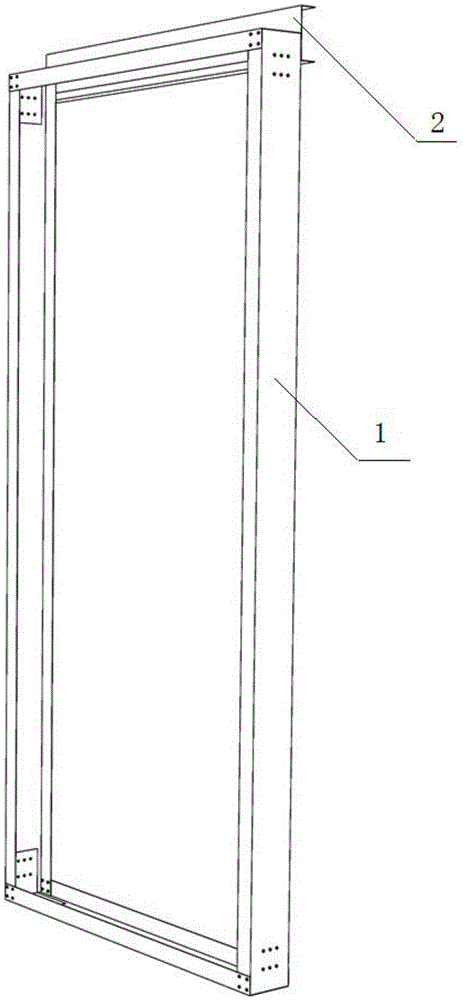

[0057] like figure 1 , 2 As shown, a standard modular assembly for construction in this embodiment includes a frame body 1 and an external C-shaped steel member 2; wherein the outer frame of the frame body 1 is in the shape of a mouth; the external C-shaped steel member 2 is located in the frame body 1. It is connected to one side of the outer frame of the frame body 1 in its length direction, and partially extends out of the outer frame of the frame body 1 in its width direction.

[0058] A preferred solution is that the mouth-shaped outer frame is formed by combining and connecting four C-shaped steel members, and the C-shaped openings of the four C-shaped steel members face the inside of the frame. The connections between the C-shaped steel members are all bolted. The above four C-shaped steel members and the external C-shaped steel member 2 are preferably cold-formed thin-walled steel.

[0059] The above s...

Embodiment 2

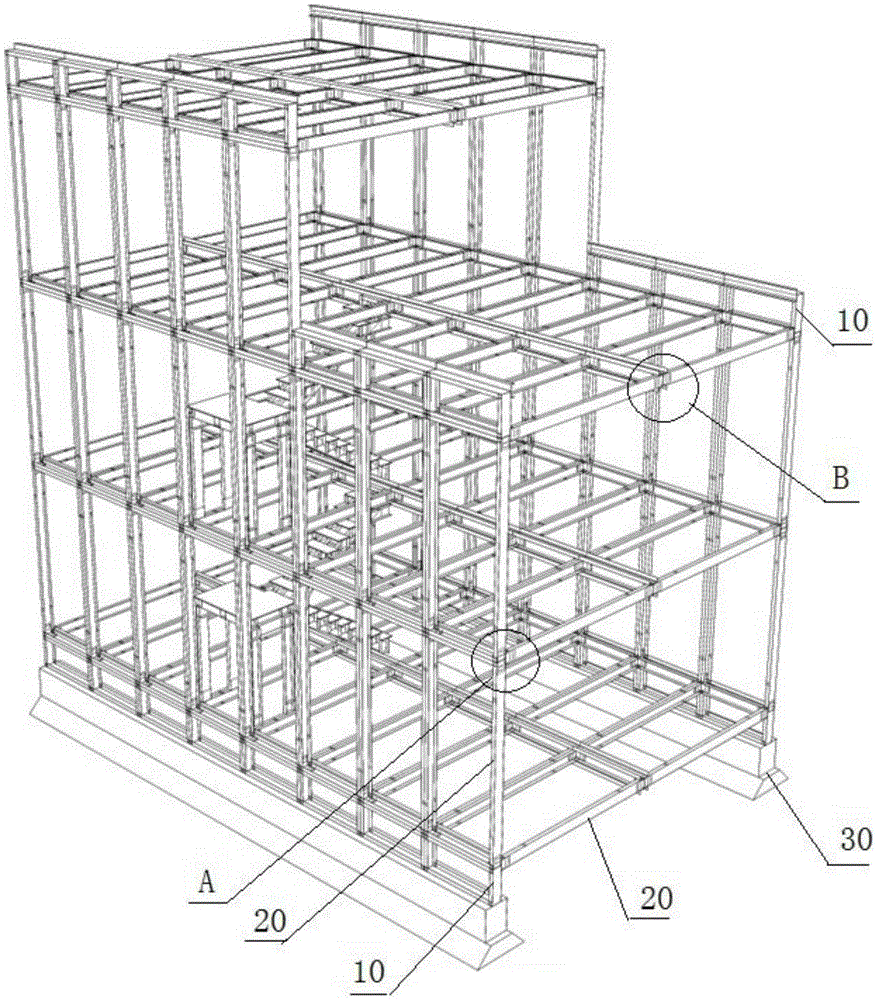

[0065] Example 2 Prefabricated building containing standard modular components for construction

[0066] A prefabricated building of this embodiment includes a building structure frame assembled from the standard modular components for building in Embodiment 1.

[0067] The following takes the preferred standard modular assembly for construction (in two types, the first assembly and the second assembly) in Embodiment 1 as an example for detailed description.

[0068] Specifically as Figure 3-5 As shown, a prefabricated building also includes two strip foundations 30 supporting the above-mentioned building structural frame; the first floor of the building adopts the method of overhead floor instead of the ground method.

[0069] The vertical side wall of the lowermost floor of the above-mentioned prefabricated building is composed of a plurality of first components 10 fixedly connected to the strip foundation 30. The external C-shaped steel member of the first component 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com