Movable assembly type heating furnace capable of carrying out electric heating in furnace to eliminate stress and construction method thereof

An electric heating and assembly technology, applied in the field of heating furnaces, can solve the problems of inability to disassemble and reuse, and the heating efficiency of large heat treatment furnaces is low, and achieves the effects of good stress relief, convenient reuse and high efficiency.

Pending Publication Date: 2020-02-21

CHINA CHEM ENG SECOND CONSTR

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The invention provides a mobile assembly type heating furnace capable of electric heating to relieve stress in the furnace and its construction method, aiming to solve the technical problems of low heating efficiency and inability to disassemble and reuse in large heat treatment furnaces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0061] In a preferred embodiment, the furnace body board 2 includes a first furnace body board 2 and a second furnace body board 2 , the size of the first furnace body board 2 is 6425mm×1500mm, and the size of the second furnace body board 2 is 1050mm×1500mm. The furnace body plate 2 of two sizes can be conveniently applied to various installation areas, thereby improving the overall installation effect.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

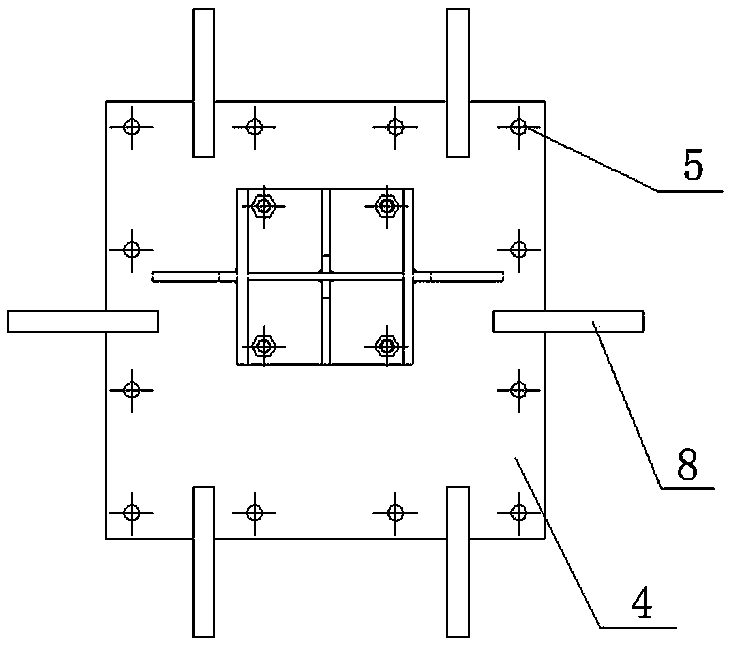

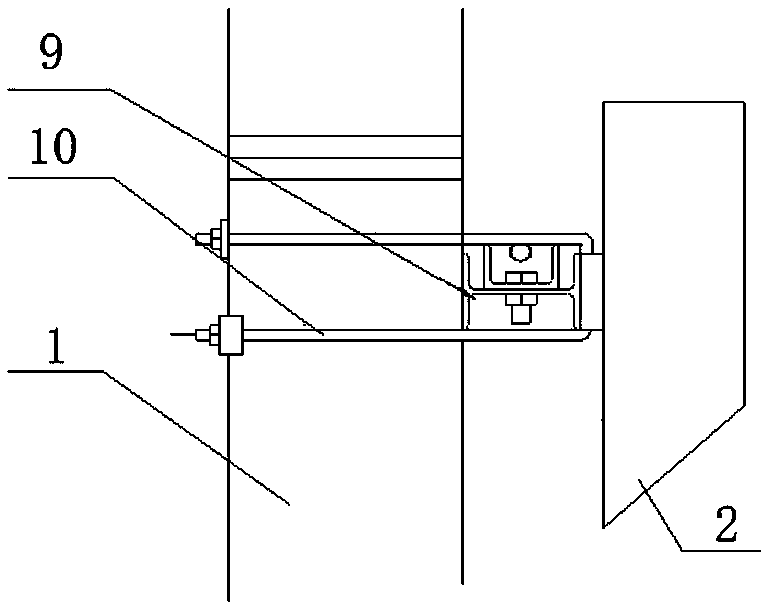

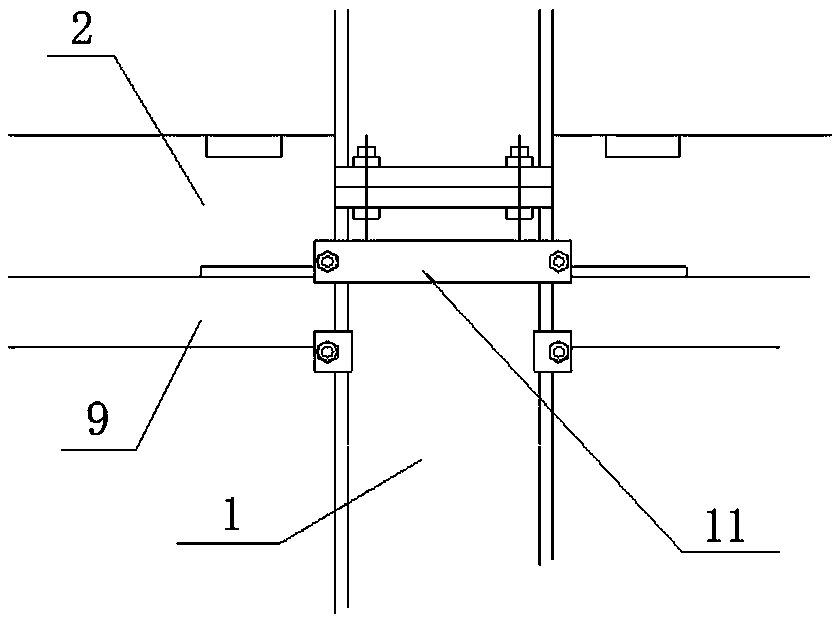

The invention relates to a movable assembly type heating furnace capable of carrying out electric heating in the furnace to eliminate stress and a construction method thereof. The heating furnace comprises ground beams, stand columns, a furnace cover, furnace body plates, a temperature measuring device, an electric heating device and a component support. A plurality of ground beams are spliced toform a plane furnace bottom. Base anchors are welded to the bottoms of the stand columns. The stand columns and the ground beams are vertically connected by the adoption of bolts. A plurality of furnace body plates are laid between the stand columns and on the inner side of the furnace cover. The temperature measuring device comprises a plurality of thermocouples and temperature recorders. The electric heating device comprises temperature control cabinets and a plurality of electric heating plates. The temperature control cabinets and the thermocouples are connected by the adoption of compensating lead wires. According to the heating furnace, in the process of centralized overall heat treatment of an installing and welding framework of a steel structure framework, centralized heat treatment of all the processes of heat treatment can be completed at a time; compared with a traditional electric heating fin tying method adopting local heat treatment, the heating furnace has the characteristics that construction is convenient, the stress eliminating effect is good, the recycling rate of a heat preserving material is high, consumed labor time is short, the cost is low, and efficiency ishigh; the heat treatment quality is ensured, the first-pass yield of heat treatment is increased greatly, the site installing efficiency is improved greatly, all joints can be assembled and disassembled rapidly, and recycling is convenient.

Description

technical field [0001] The invention belongs to the field of large-scale heat treatment furnaces, and in particular relates to a movable assembly type heating furnace capable of relieving stress by electric heating in the furnace. Background technique [0002] At present, the design of the basic joint connection methods of industrial steel structures is basically two types: bolt connection and welding. Rivet connection is generally used in bridge engineering. The core part of the 1 million tons / year flexible coking unit is the reaction zone. This area mainly has 3 large pieces of equipment: Reactor (R101), Heater (R102) and Gasifier (R103). The operating temperature of the reactor is about 600°C, and the equipment has an amplitude of 5.6mm per meter, which increases sequentially with the height of the equipment, and the amplitude can reach 300mm at the top of the equipment; because the fluid in the pipeline is solid-liquid mixed coke, the operating fluid in the pipeline is u...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F27B17/00

CPCF27B17/00

Inventor 姚武涛杨德仁邓彦生杨广韩春光

Owner CHINA CHEM ENG SECOND CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com