Cable clamp

The technology of a cable clip and a cable clip body is applied in the field of cable clips, which can solve the problems of potential safety hazards, low installation efficiency, unfavorable maintenance, etc., and achieve the effects of improving safety, reducing construction costs, and having a simple and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

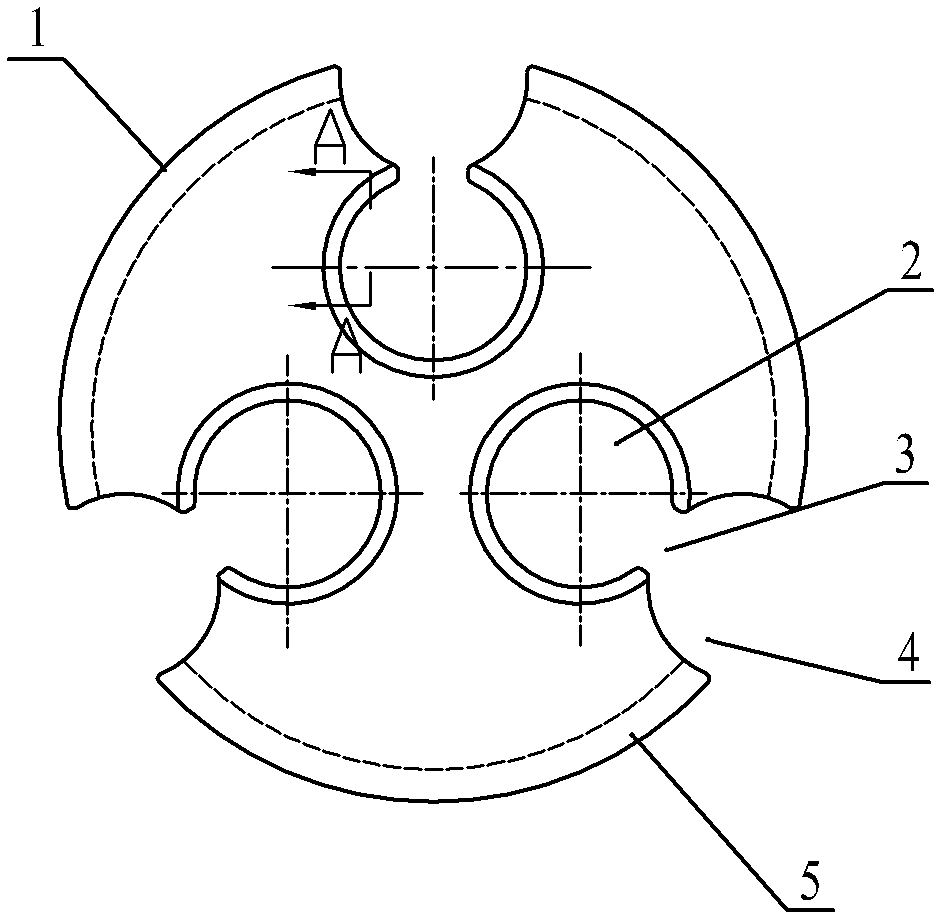

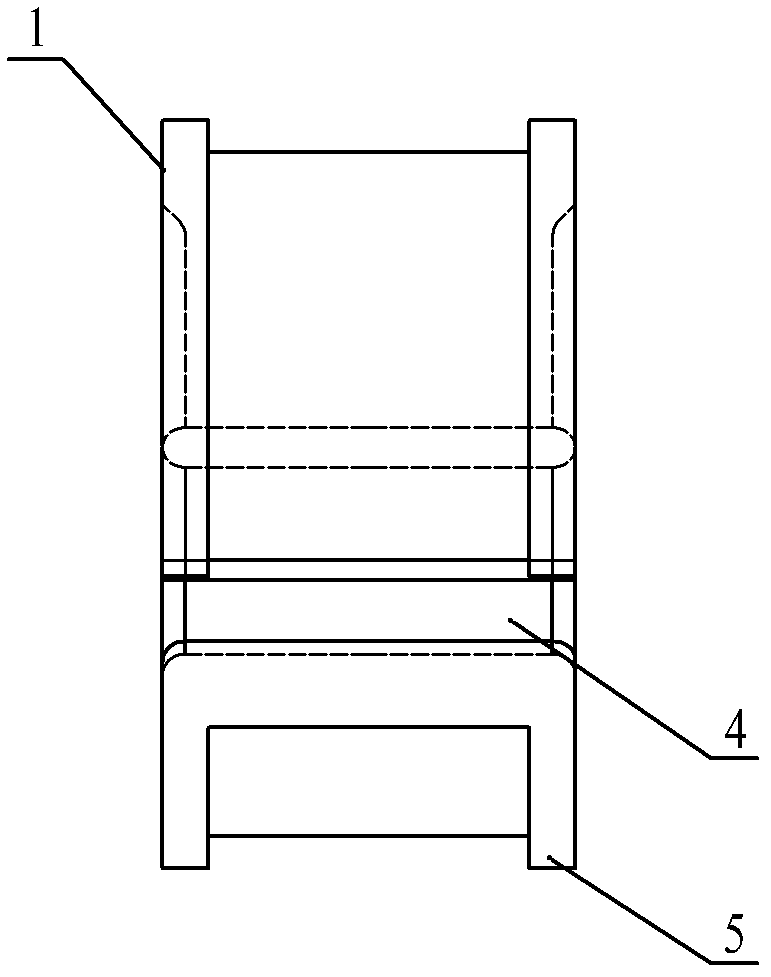

[0013] Such as figure 1 , figure 2 As shown, the cable clamp of the present invention is used to organize and fix cables, and it is particularly suitable for finishing and fixing cables of locomotives. The cable clamp includes a clamp body 1, which is a cylinder made of rubber material. The clamp body 1 is provided with three axial wire holes 2 uniformly distributed along the circumferential direction. There are three wire inlet passages for enabling cables to enter the wire holes 2 . The clamp body 1 is preferably made of rubber with a hardness of 70±5HA.

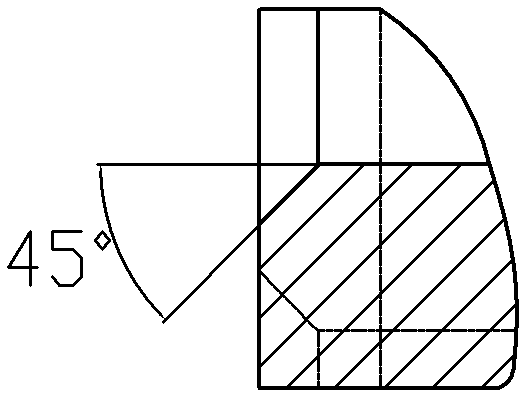

[0014] Such as figure 1 , figure 2 As shown, the outer edge of the clamp body 1 is provided with three axial line entry notch slots 4 uniformly distributed along the circumferential direction, the line entry notch slots 4 correspond to the line holes 2 one by one, and the line entry notch slots 4 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com