Earthquake-proof folk house steel framework and installation method thereof

A steel frame and dwelling technology, applied to building components, building structures, floor slabs, etc., can solve problems such as difficulty in meeting high-speed, high-quality construction requirements, hidden dangers of construction personnel in the air, and affecting project quality, etc., to improve on-site The effect of installation efficiency, reduction of backlog, and reduction of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the patent of the present invention is described further.

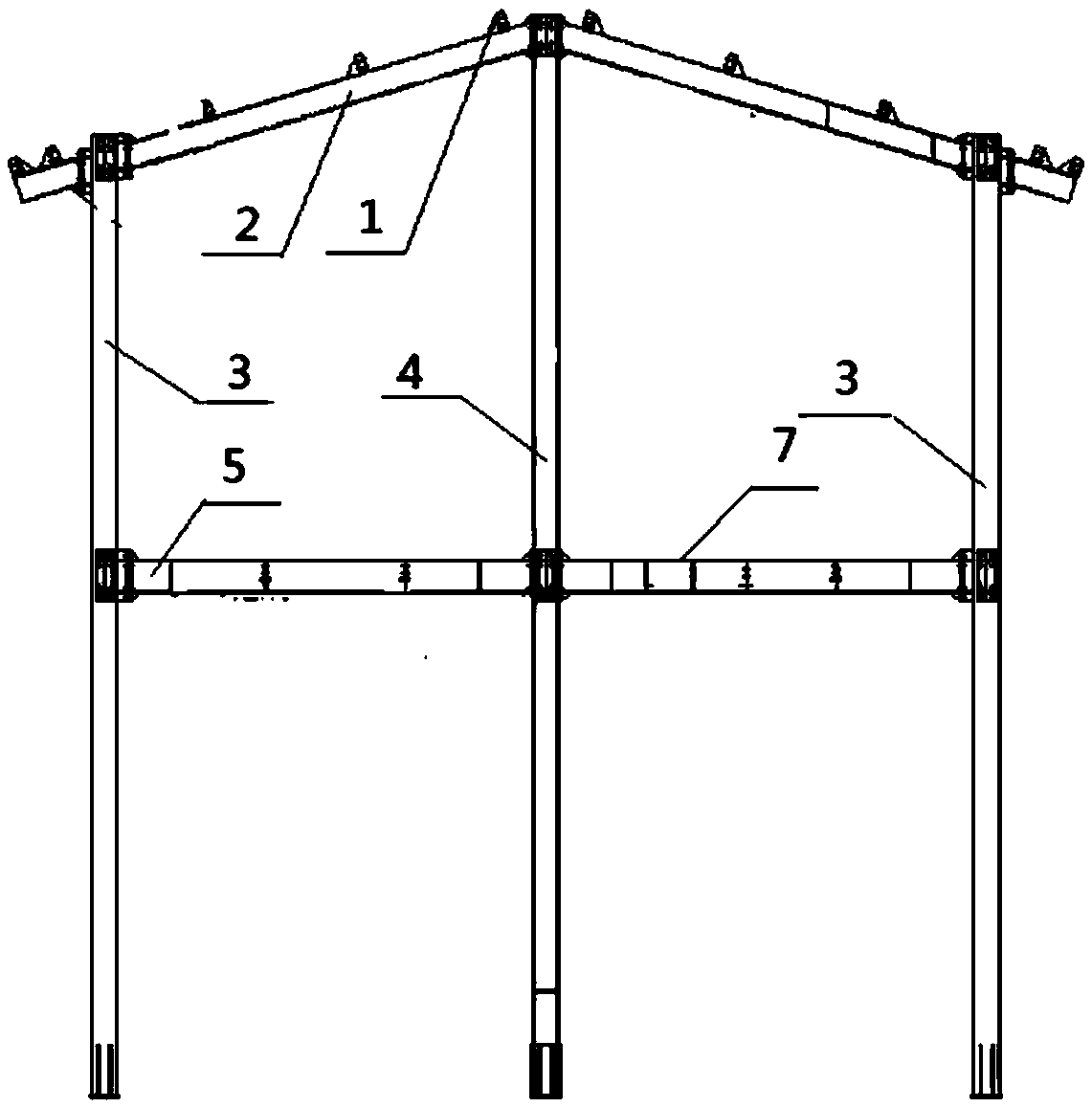

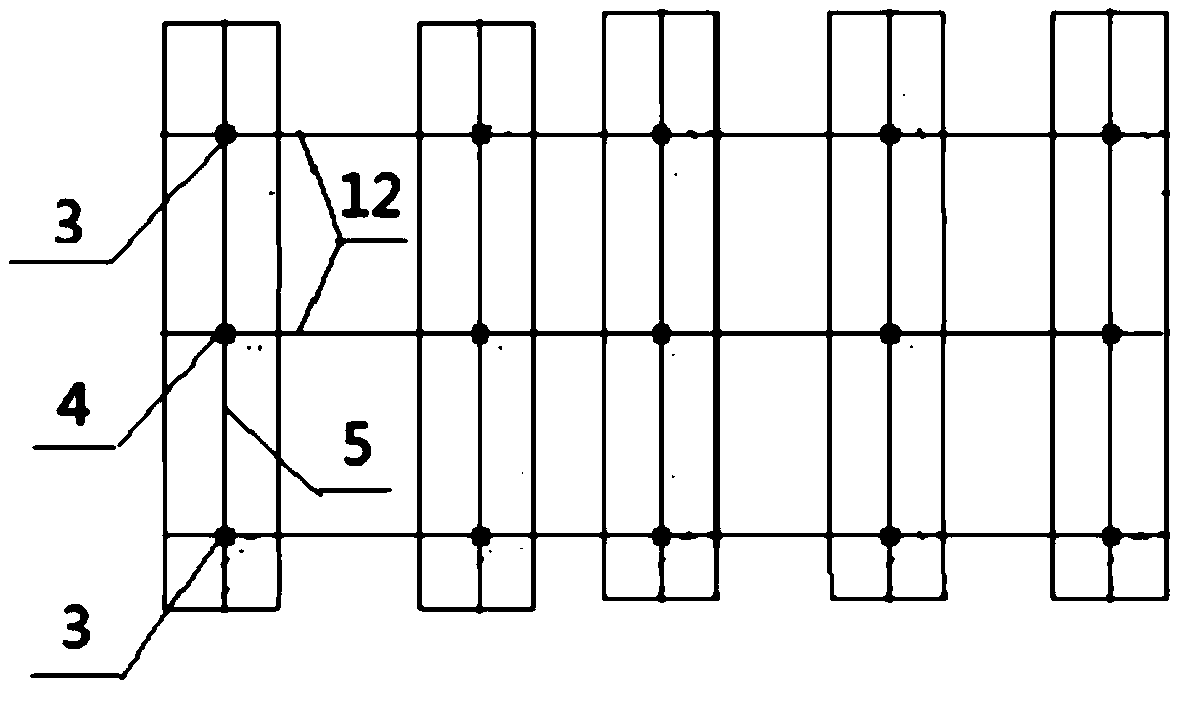

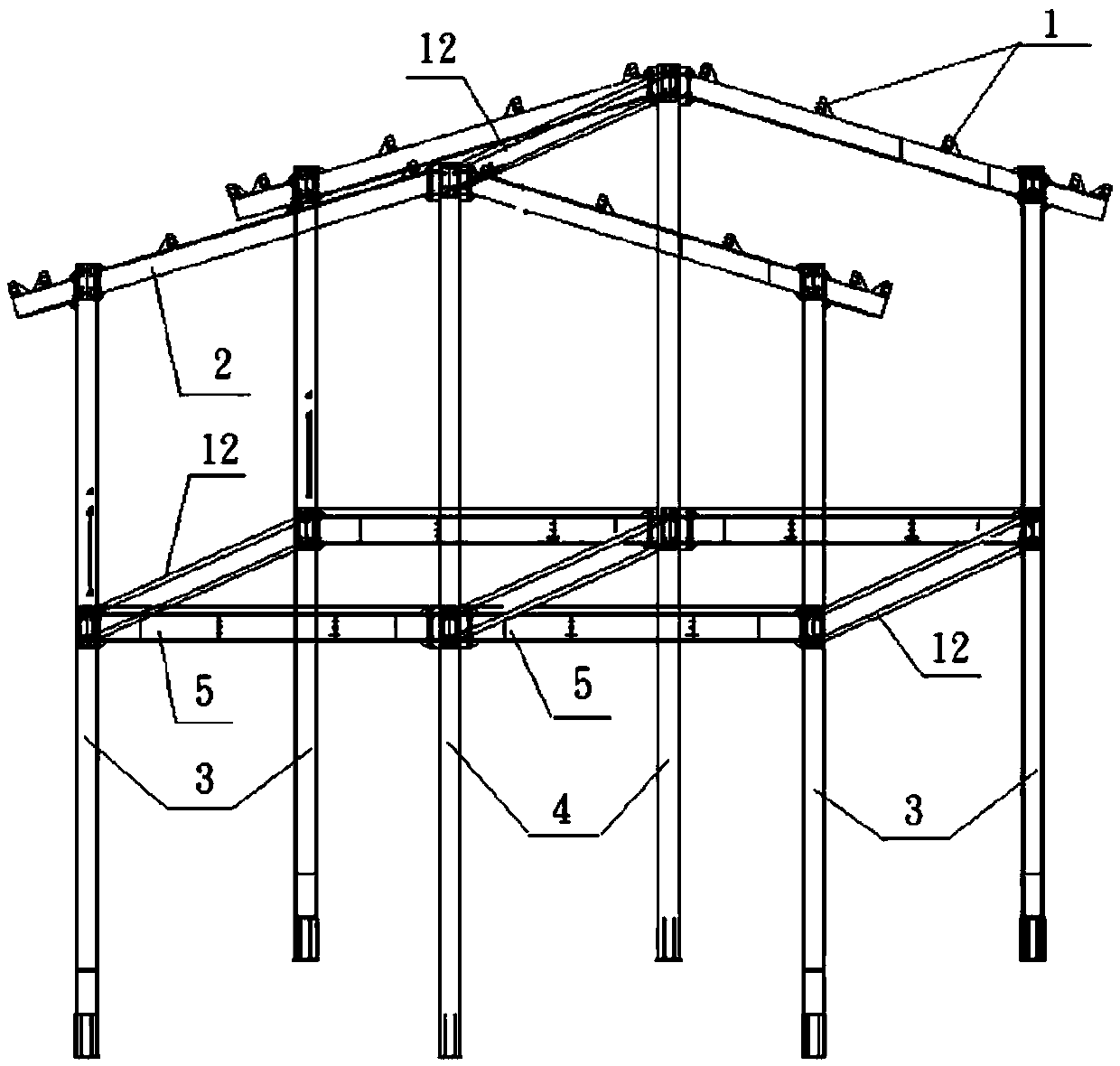

[0032] As shown in the figure, the earthquake-resistant residential steel frame includes several integrated beam and column units, and several horizontal floor deck integrated units 7, each beam and column integrated unit includes two roof beams 2 overlapping herringbone, The tower is connected between the two roof beams 2 and the center column 4 extending downward, the tower is respectively connected to the sides or ends of the two roof beams 2 and the side column 3 extending downward, the tower is connected between the center column 4 and the side The horizontal beams 5 between the columns 3 and perpendicular to the central column 3 and the side columns 4, the plurality of beam and column integrated units are arranged side by side at intervals according to the length of the house to be built. The horizontal longitudinal beams 12 are connected, and the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com