Combined fast-assembly pipeline support and mounting method thereof

A pipe support and combined technology, applied in the direction of pipe support, pipes/pipe joints/fittings, sheet pile walls, etc., can solve the problems of lower construction quality and on-site installation efficiency, long construction period, and heavy adjustment workload, etc., to achieve Improve the efficiency of on-site installation, overcome the inability to adjust the height, and support stable and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

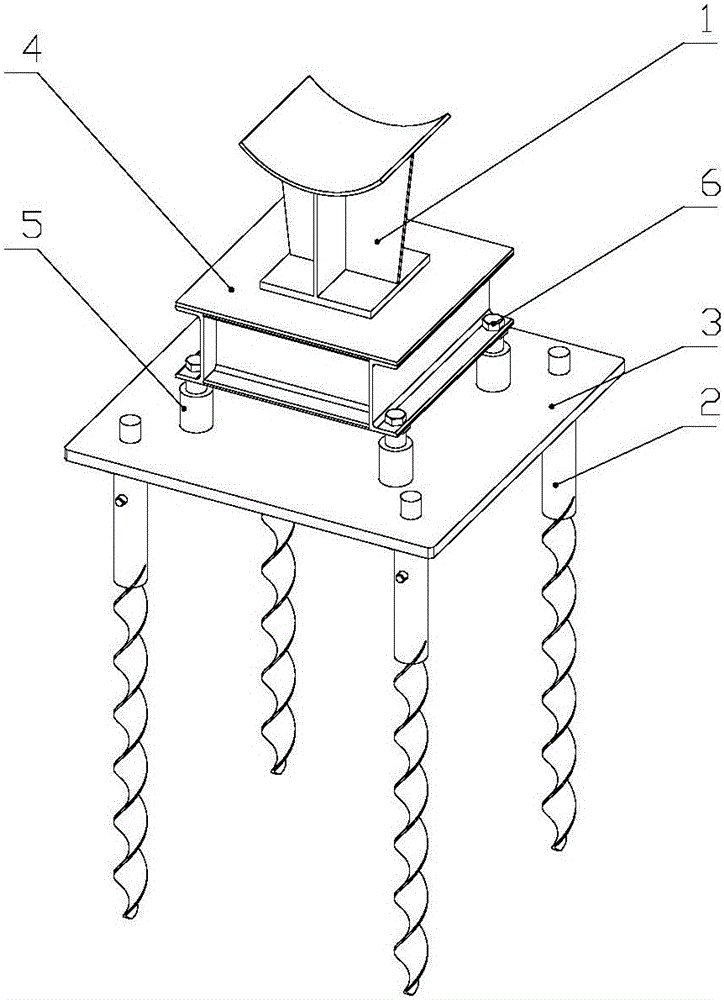

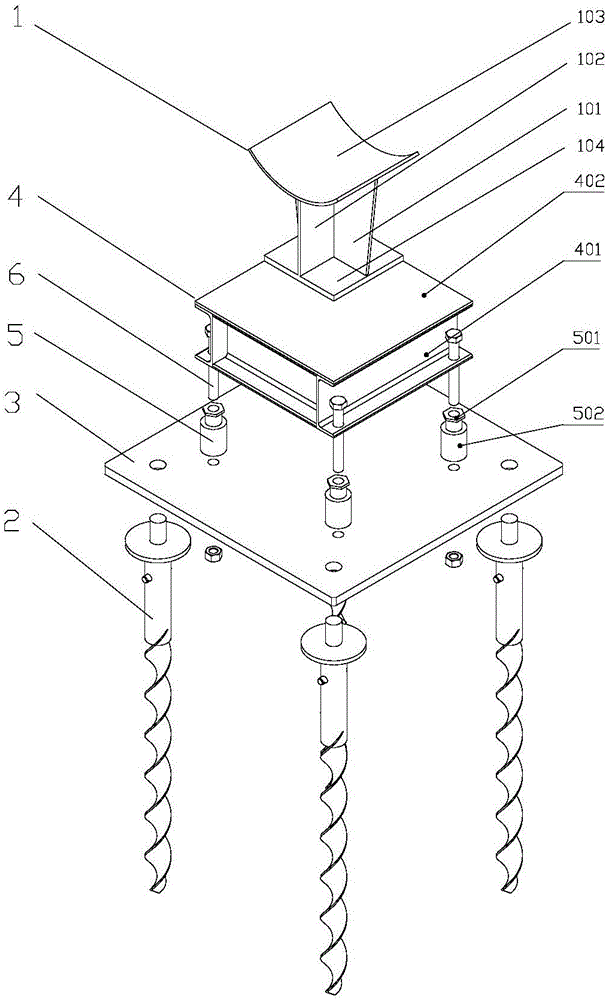

[0027] The combined quick-install pipe support of this embodiment is as follows: Figure 1 to Figure 5 As shown, it includes a pipe holder 1 supported on a rectangular upper panel 402 of a base 4 , and the four corners of the base 4 are respectively placed on a rectangular base plate 3 through a height adjustment device 5 . The four corners of the foundation plate 3 are respectively supported on four adjustable piles 2 .

[0028] The pipe support 1 is composed of a vertical plate 102 with reinforcing ribs 101 on both sides and a bottom plate 104 at its lower end to form a lower bottom support, and then welded and fixedly connected with an arc support 103 at the top.

[0029] The base 4 is welded and fixedly connected by a channel steel support 401 surrounding a rectangular frame and a top panel 402 to form a stable support.

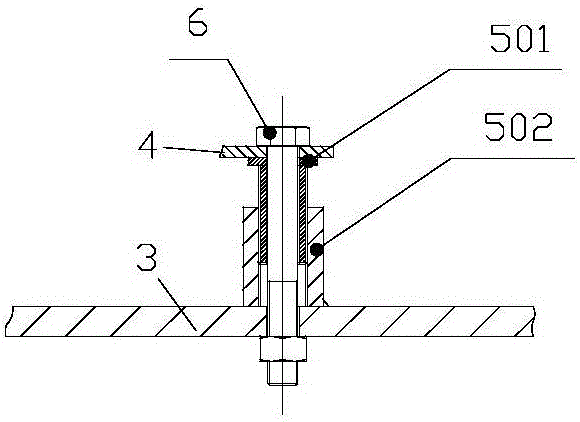

[0030] The height adjustment device 5 is essentially a pair of vertical spiral sub-components respectively arranged on the base plate 3 and supported un...

Embodiment 2

[0039] The difference between the pipe support of this embodiment and the first embodiment is as follows: Figure 6 As shown, the helical section of the drill pipe of the adjustable pile is an outer winding structure.

Embodiment 3

[0041] The difference between the pipe support of this embodiment and the second embodiment is as follows: Figure 7 As shown, the helical section of the drill pipe of the adjustable pile has a structure of discontinuous blades around the outside of the steel pipe, which can produce a certain intermittent impact during precession, and is suitable for operations where there are many gravels.

[0042] Practice has proved that the pipe support of the above embodiment has the following advantages:

[0043] 1) By fine-tuning the height of each adjustable pile, the level of the foundation slab can be adjusted, which overcomes the disadvantage that the pre-embedded slab of the traditional concrete pile foundation support cannot be adjusted;

[0044] 2) The height of the bracket can be adjusted by adjusting the height adjustment device. Not only can the height be adjusted according to the elevation requirements during installation, but also after the base is installed, the height adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com