Planetary gear rack and manufacture method thereof

A technology of planetary gear carrier and manufacturing method, which is applied in the direction of belt/chain/gear, transmission device parts, metal processing equipment, etc., and can solve the problems of poor material yield, large number of parts, and large number of processing procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

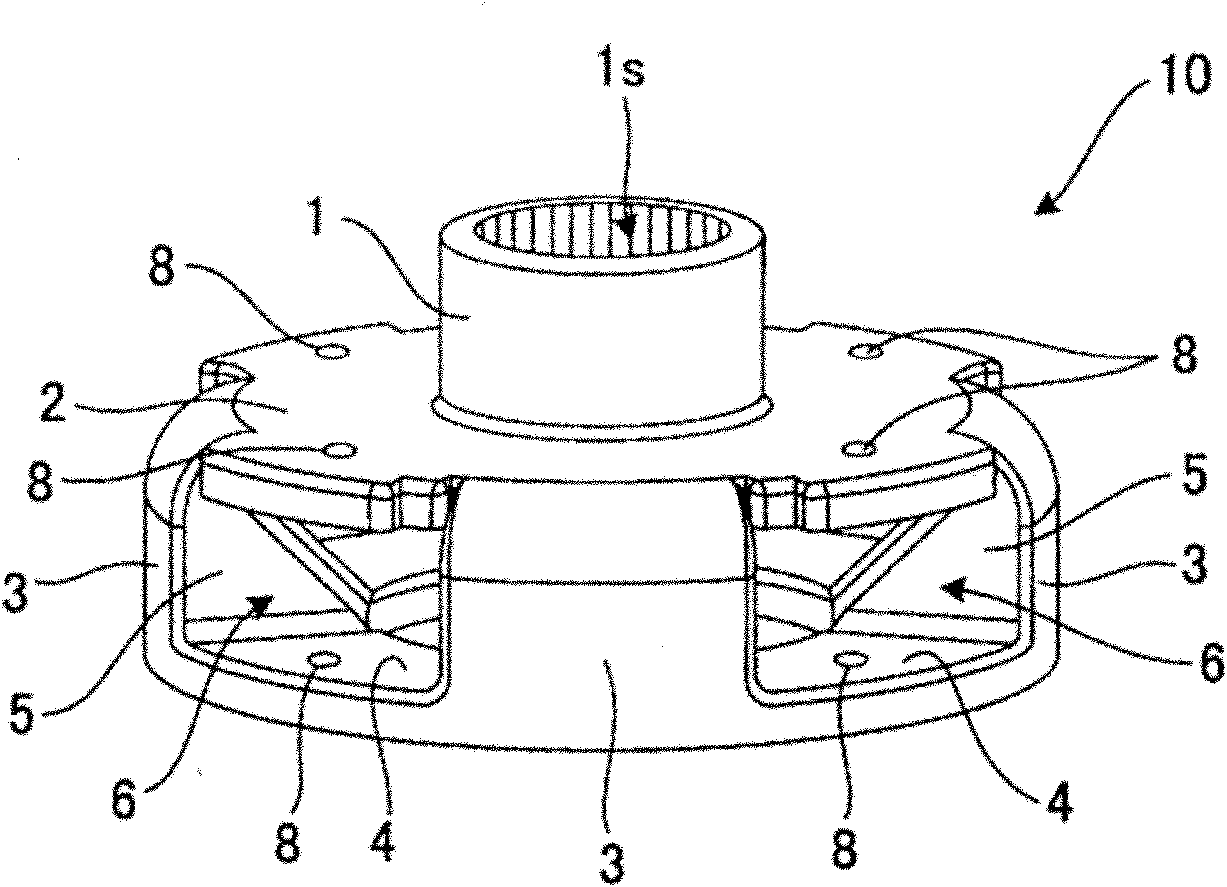

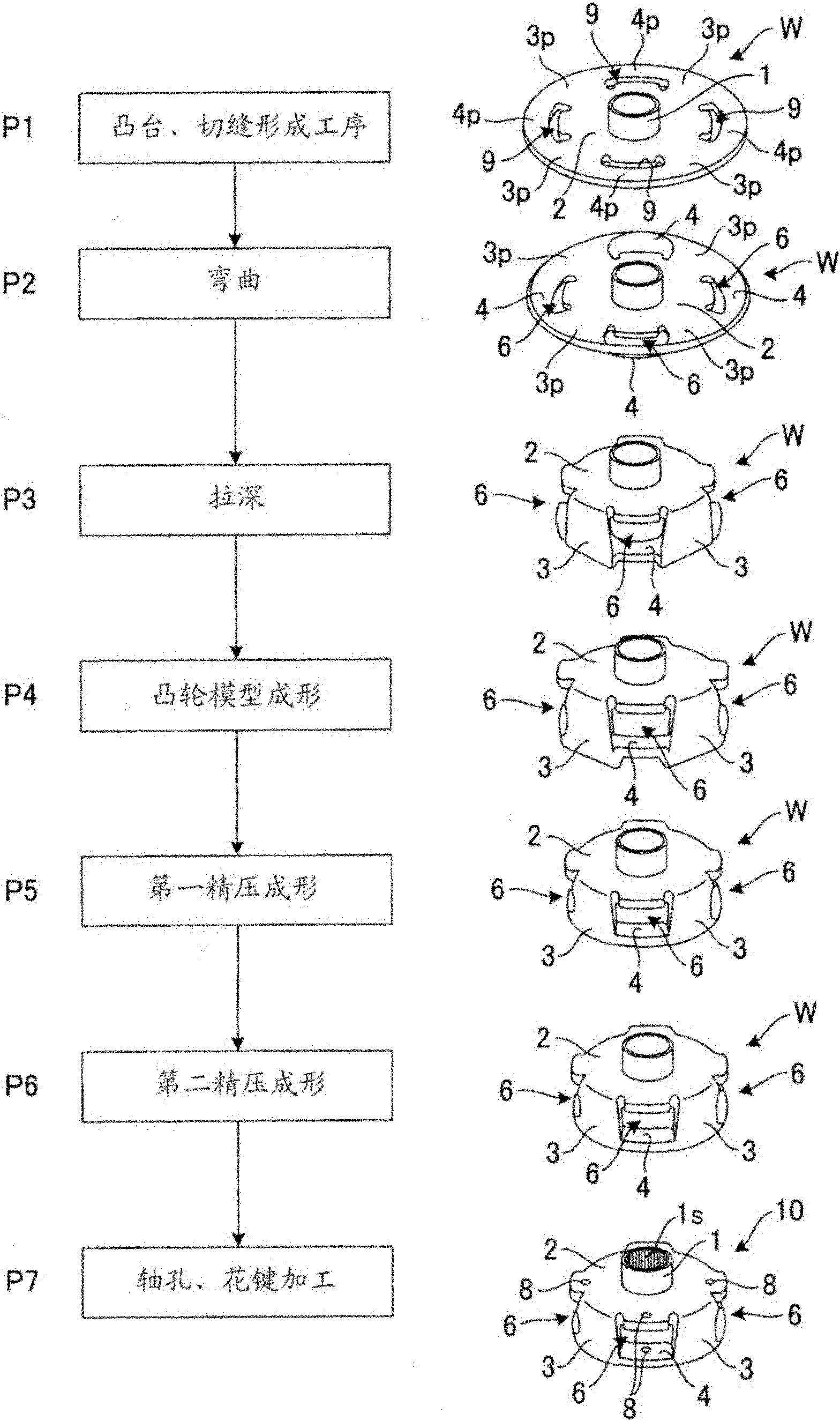

[0037] figure 1 The planetary carrier 10 manufactured by the manufacturing method of embodiment of this invention is shown. The carrier 10 is one of the components of the planetary gear mechanism, and rotatably supports a pinion gear that is also one of the components of the planetary gear mechanism.

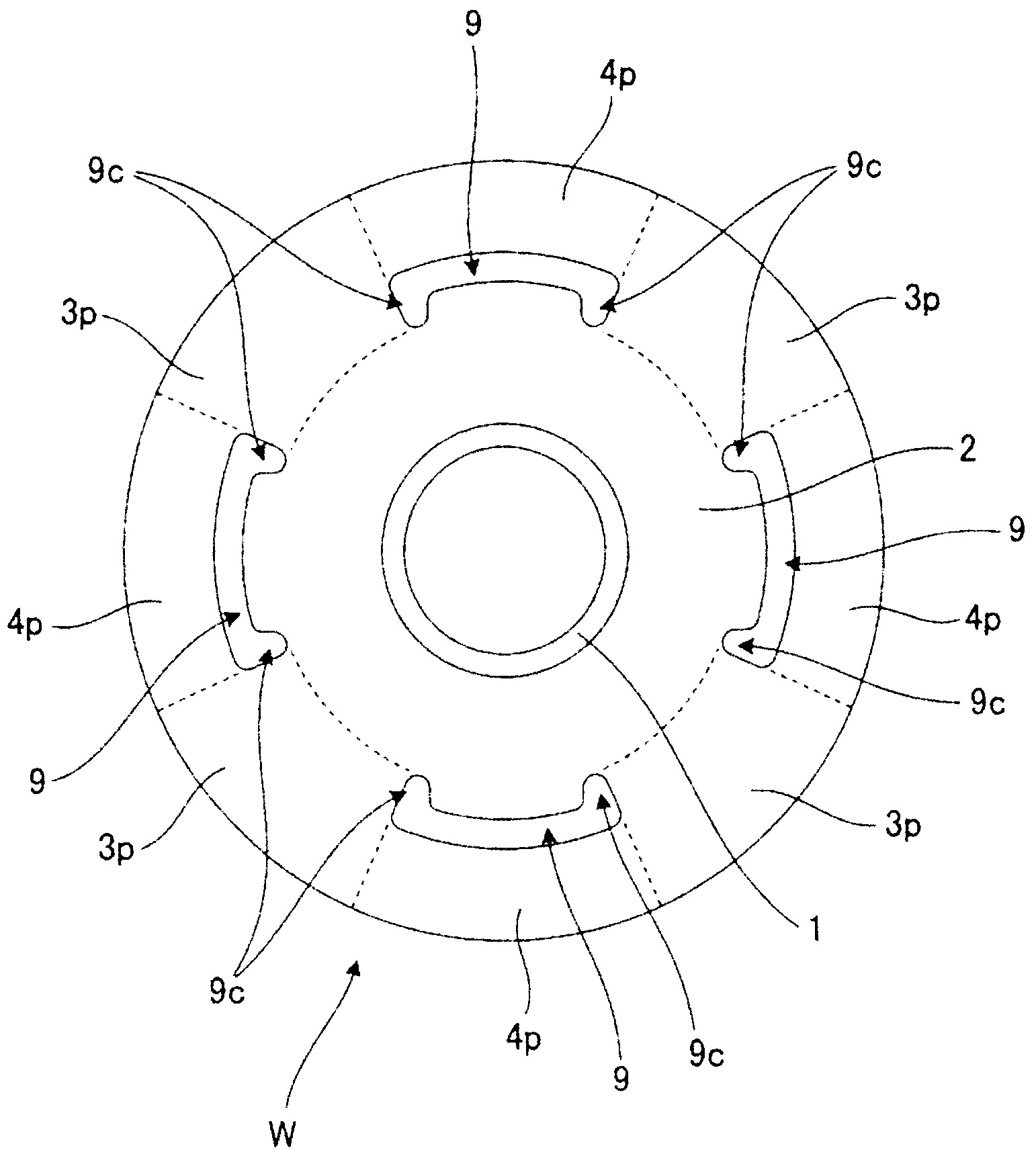

[0038] The planetary gear carrier 10 has: a boss 1 with a spline groove 1s inside, a flange 2 extending radially from the lower end of the boss 1, a side wall 3 connected to the flange 2, and a side wall 3 facing the planet from the side of the planetary gear carrier 10. A seating surface 4 extending inside the gear carrier 10 and parallel to the flange 2 .

[0039] The flange 2 and the sides of the planetary gear carrier 10 are integrally formed by one part. Seat surface 4 is a surface initially on the same side as the upper surface of flange 2 , and is formed by subm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com