Method for plasma graft weight gaining of real silk fabric

A silk fabric and plasma technology, applied in animal fiber, textiles, papermaking, fiber treatment, etc., can solve the problems of difficult wastewater treatment, difficulty in industrialized production, high cost of rare earth, etc., and achieve the effect of improving the degree of bonding and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

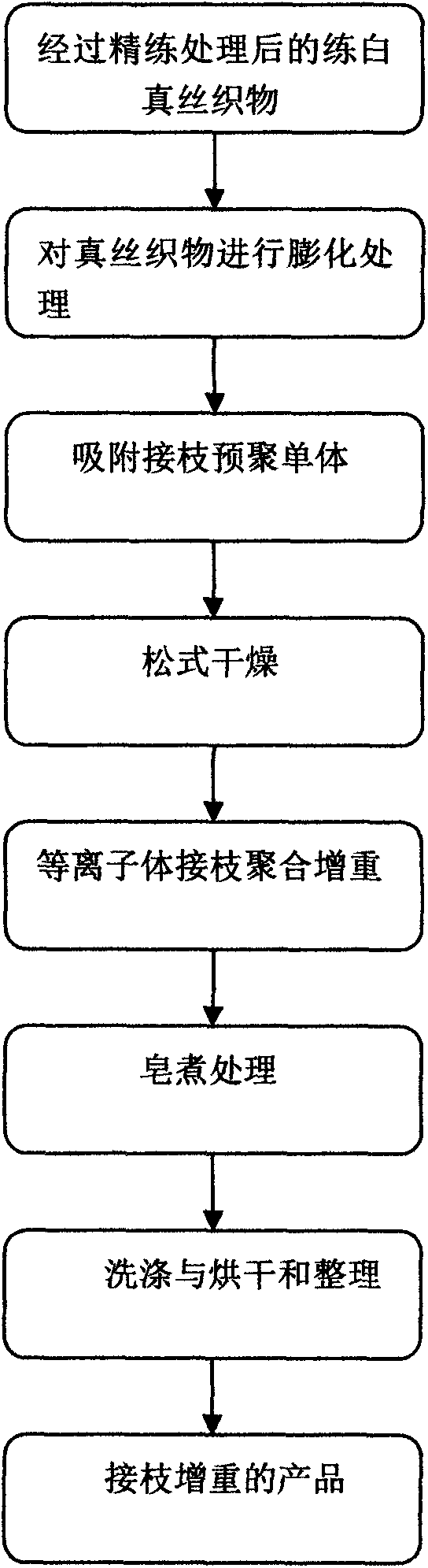

[0031] See attached figure 1 , the pre-polymerized monomer of the present embodiment adopts polyhydroxyethyl methacrylate (about 1000 number-average molecular weight), and the processing method of weight gain 16 electric spinning (10 mm, 114cm width) comprises the following steps: prepare 16 electric spinning Embryo, scouring treatment, puffing treatment, graft liquid adsorption, loose drying, plasma graft polymerization weight gain, soaping treatment, washing and drying and finishing steps.

[0032] In the scouring treatment step of scouring agent, the silk fast scouring agent and conventional process are used to remove sericin protein, followed by one wash with hot water at 90°C, one wash with warm water at 60°C, one wash with cold water at room temperature, and then centrifugal dehydration.

[0033] The scoured real silk fabric is puffed in the puffing liquid composed of the following components, (A) alkali metal carbonate, the addition is 15%; (B) calcium, magnesium ion or...

Embodiment 2

[0045] See attached figure 1 , the pre-polymerized monomer of the present embodiment adopts polymethacrylic acid (number-average molecular weight about 1500), and the processing method of weight gain 01 double wrinkle (12 mmm, 114cm width) comprises the following steps: prepare 01 double wrinkle green embryo, Scouring treatment, puffing treatment, adsorption of grafting liquid, pine drying, plasma graft polymerization weight gain, soaping treatment, washing, drying and finishing steps.

[0046] In the scouring treatment step of scouring agent, the silk fast scouring agent and conventional process are used to remove sericin protein, followed by one wash with hot water at 90°C, one wash with warm water at 60°C, one wash with cold water at room temperature, and then centrifugal dehydration.

[0047] The scoured real silk fabric is puffed in the puffing liquid composed of the following components, (A) alkali metal carbonate, the addition is 20%; (B) calcium, magnesium ion or heavy...

Embodiment 3

[0059] See attached figure 1 , the present embodiment pre-polymerization monomer adopts polymethyl methacrylate (about 1200 of number-average molecular weight), and the processing method of weight gain 01 real silk georgette fabric (8 mm, 114cm width) comprises the following steps: prepare 01 real silk Georgette embryo, scouring treatment, puffing treatment, graft liquid adsorption, pine drying, plasma graft polymerization weight gain, soaping treatment, washing, drying and finishing steps.

[0060] In the scouring treatment step of scouring agent, the silk fast scouring agent and conventional process are used to remove sericin protein, followed by one wash with hot water at 90°C, one wash with warm water at 60°C, one wash with cold water at room temperature, and then centrifugal dehydration.

[0061] The scoured real silk fabric is puffed in the puffing liquid composed of the following components, (A) alkali metal carbonate, the addition is 15%; (B) calcium, magnesium ion or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com