Plastic with good thermal conductivity and preparation method thereof

A thermal conductivity and plastic technology, applied in the field of plastics with good thermal conductivity and its preparation, can solve the problems of poor thermal conductivity, affecting the service life and performance of electronic products, hindering heat dissipation, etc., achieving good wear resistance and not easy The effect of being scratched and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

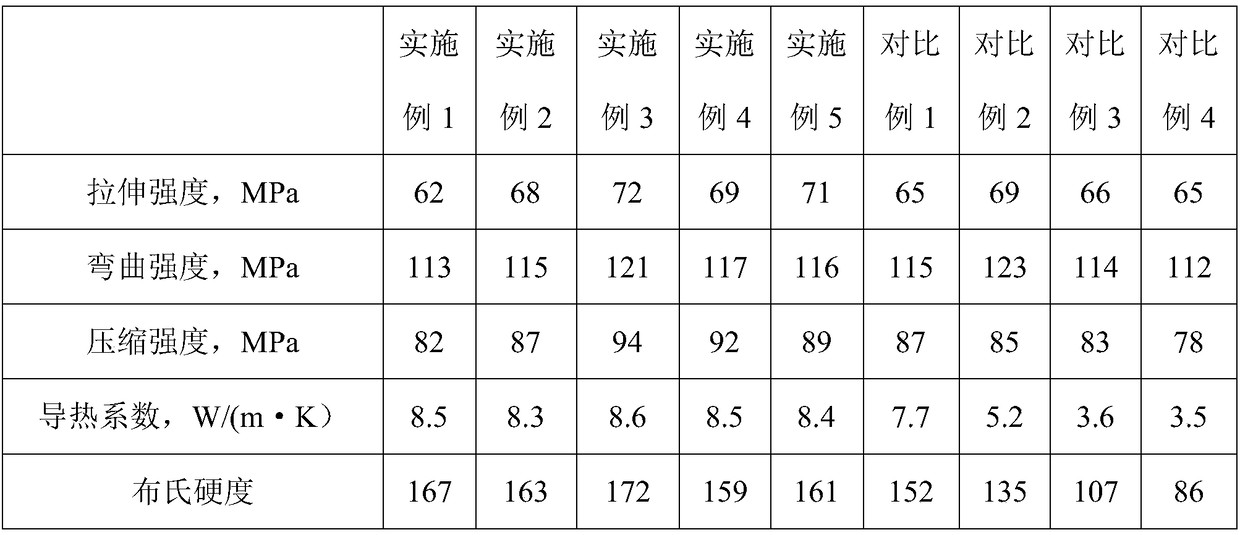

Examples

Embodiment 1

[0021] A plastic with good thermal conductivity, comprising the following raw materials in parts by weight: 80 parts of polycarbonate, 30 parts of polybutylene adipamide, 10 parts of polyolefin elastomer, 5 parts of calcium carbonate, 8 parts of silicon carbide, 6 parts of alumina, 5 parts of graphene, 4 parts of diamond powder, 3 parts of glass fiber, 5 parts of silane coupling agent, 30 parts of polyethylene glycol, 4 parts of 2-hydroxy-4-methoxybenzophenone, 2 parts of calcium stearate, 3 parts of 2,4-dichlorobenzoyl peroxide.

[0022] Wherein, the glass fiber is an alkali-free glass fiber with a length of 10 mm and a diameter of 5 μm.

[0023] Wherein, the silane coupling agent is KH550.

[0024] In this embodiment, the preparation method of the plastic with good thermal conductivity, the steps are as follows:

[0025] 1) Put polycarbonate, polybutylene adipamide, and polyolefin elastomer into a mechanical ball mill, and simultaneously add calcium carbonate, silicon carb...

Embodiment 2

[0030] A plastic with good thermal conductivity, comprising the following raw materials in parts by weight: 90 parts of polycarbonate, 35 parts of polybutylene adipamide, 12 parts of polyolefin elastomer, 6 parts of calcium carbonate, 10 parts of silicon carbide, 8 parts of alumina, 6 parts of graphene, 5 parts of diamond powder, 5 parts of glass fiber, 9 parts of silane coupling agent, 45 parts of polyethylene glycol, 6 parts of 2-hydroxy-4-methoxybenzophenone, 4 parts of calcium stearate, 4.5 parts of 2,4-dichlorobenzoyl peroxide.

[0031] Wherein, the glass fiber is an alkali-free glass fiber with a length of 12 mm and a diameter of 8 μm.

[0032] Wherein, the silane coupling agent is KH550.

[0033] In this embodiment, the preparation method of the plastic with good thermal conductivity, the steps are as follows:

[0034] 1) Put polycarbonate, polybutylene adipamide, and polyolefin elastomer into a mechanical ball mill, and simultaneously add calcium carbonate, silicon c...

Embodiment 3

[0039] A plastic with good thermal conductivity, comprising the following raw materials in parts by weight: 100 parts of polycarbonate, 40 parts of polybutylene adipamide, 15 parts of polyolefin elastomer, 8 parts of calcium carbonate, 12 parts of silicon carbide, 9 parts of alumina, 7 parts of graphene, 6 parts of diamond powder, 4.5 parts of glass fiber, 8 parts of silane coupling agent, 40 parts of polyethylene glycol, 5.5 parts of 2-hydroxy-4-methoxybenzophenone, 3.5 parts of calcium stearate, 4 parts of 2,4-dichlorobenzoyl peroxide.

[0040] Wherein, the glass fiber is an alkali-free glass fiber with a length of 12 mm and a diameter of 8 μm.

[0041] Wherein, the silane coupling agent is KH550.

[0042] In this embodiment, the preparation method of the plastic with good thermal conductivity, the steps are as follows:

[0043] 1) Put polycarbonate, polybutylene adipamide, and polyolefin elastomer into a mechanical ball mill, and simultaneously add calcium carbonate, sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com