Light heat insulating sound proofing wall partition board and its production method

A technology for thermal insulation and sound insulation and partition panels, which is applied in the field of lightweight thermal insulation and sound insulation partition panels and house partition walls. The lightness of wall panels and other issues can be achieved to achieve the effect of strong thermal insulation and sound insulation performance, good thermal insulation and sound insulation performance, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

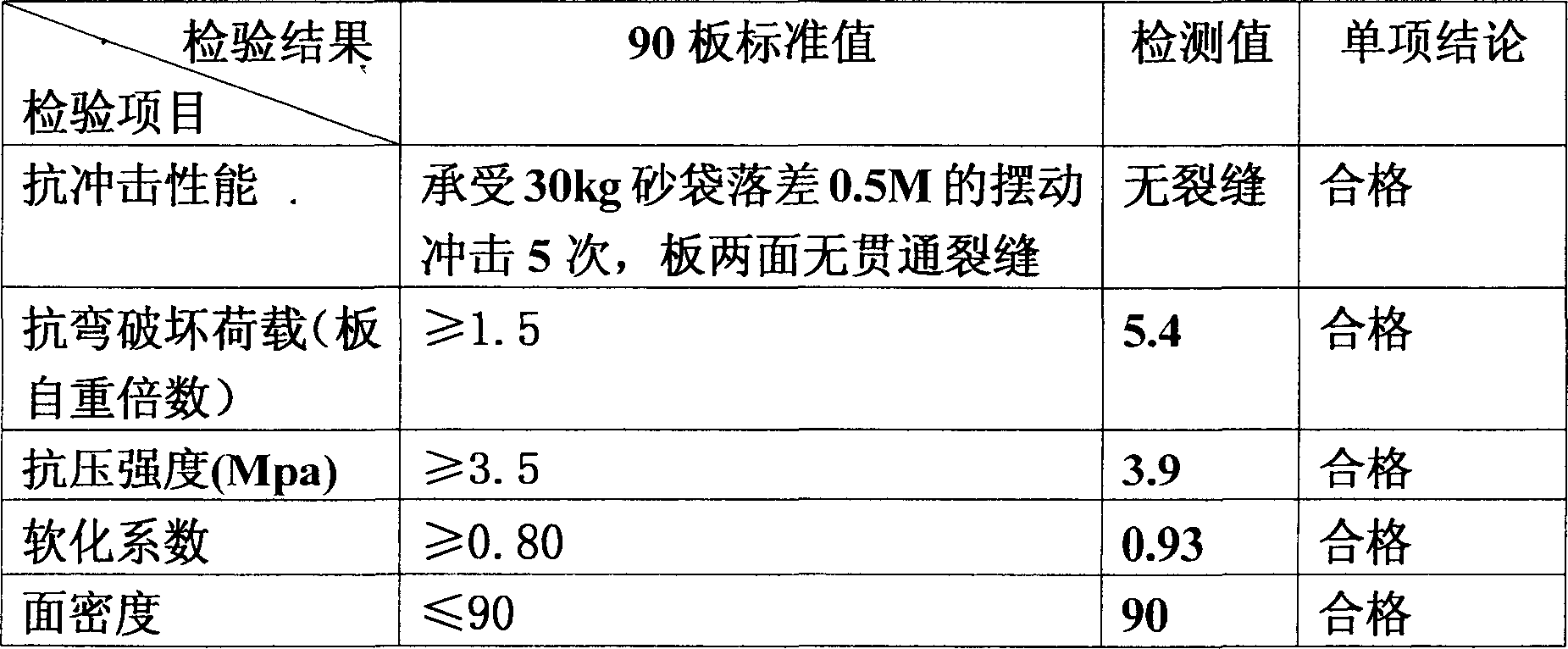

[0019] The formulation and production method of the present invention will be described in detail below according to the examples.

[0020] material name

Example 1

Example 2

Example 3

Cement (kg)

100

100

100

50

80

130

Lightweight stone particles (kg)

100

150

200

Polypropylene fibers

trace

trace

trace

[0021] The cement can be made of Portland or aluminum sulfate cement, the lightweight stone particles can be pumice, basalt or shale particles, and the polypropylene fiber is preferably high-strength water-soluble polypropylene fiber.

[0022] 2. Production steps:

[0023] (1) Mixing: Take cement, light asbestos wool and light stone particles according to the weight ratio in the above formula. If the light stone particles are large, it is best to crush the particles to less than 1 cm, and put the above materials into Stir and mix in a bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com