Illumination optical unit for microlithography

An optical unit and microlithography technology, applied in microlithography exposure equipment, optical elements, optics, etc., can solve the problem of reducing the total transmission rate of the illumination optical unit, and achieve the effect of high manufacturing cost efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The reference designation is selected so that it is provided with one or two digitsfigure 1 objects shown in . Objects shown in other figures have reference numbers of three or more digits, with the last two digits representing the object and the preceding digits representing the number of the figure showing the object. Therefore, the last two digits of the reference numerals of the same objects shown in multiple figures are the same.

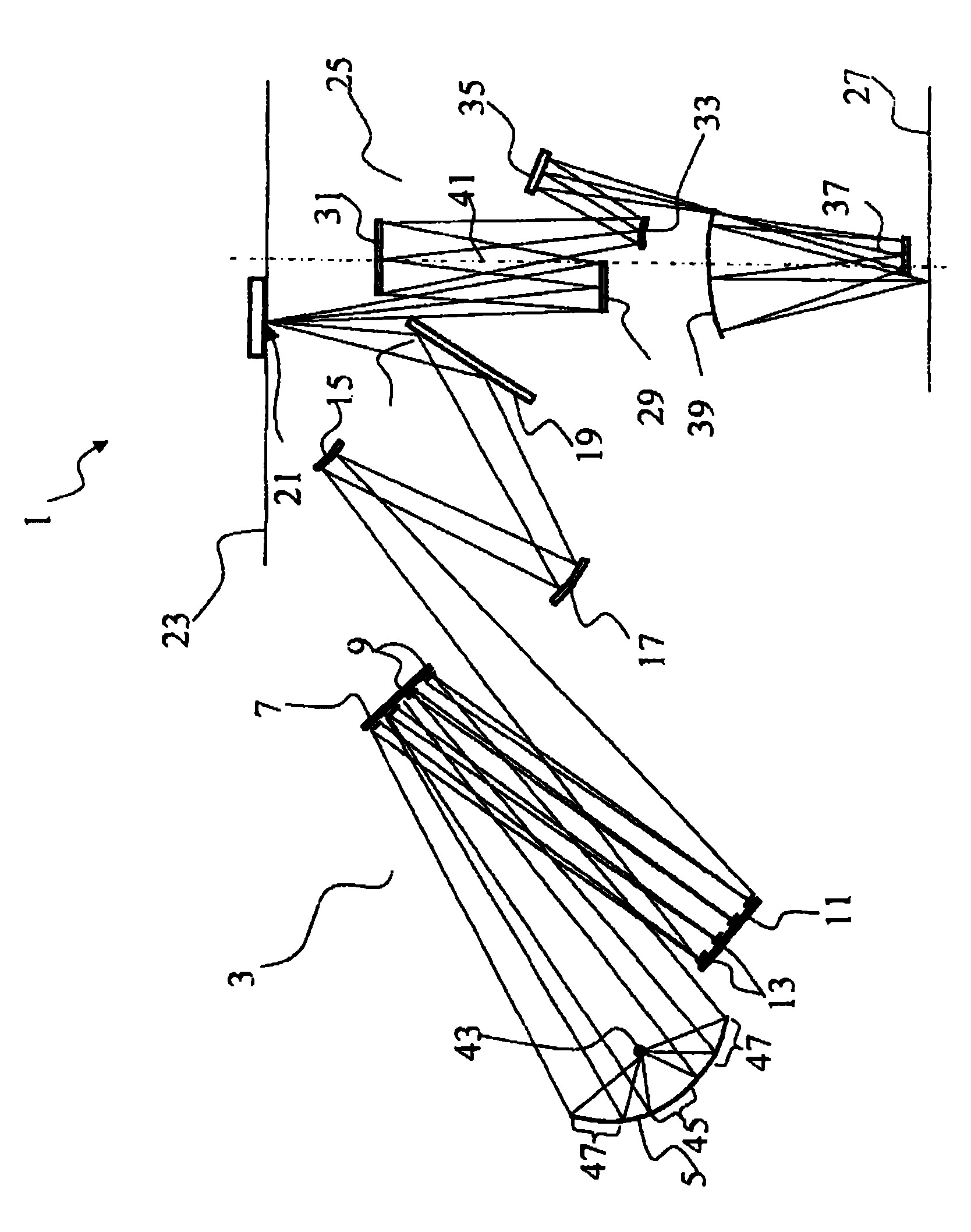

[0038] figure 1 The construction of a projection exposure system 1 according to the invention is shown, which comprises an illumination optics unit 3 . In this case, the illumination optical unit 3 comprises a mirror concentrator 5 , a first reflective optical element 7 with a first facet element 9 and a second reflective optical element 11 with a plurality of second facet elements 13 . A first telescopic mirror 15 and a second telescopic mirror 17 are arranged in the optical path downstream of the second reflective optical element 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com