Silicate cement clinker and preparation method thereof

A technology for Portland cement and clinker, applied in the field of cement manufacturing, can solve the problems of pollution discharge, increase of waste sand, waste of resources, etc., and achieve the effects of reducing firing temperature, reducing production cost, and saving firing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] As a preferred embodiment of the application, this embodiment discloses:

[0045] A portland cement clinker, comprising the following raw materials in weight percentage: Calcareous material: limestone 42-72%, siliceous material 1-20%, supplementary calcium material 10-40%, iron material 0-5% ; Iron-aluminum material 3-15%; The supplementary calcium material is limestone molding sand waste. The siliceous material is a mixture of one or more of clay, shale, quartz sand and fly ash. The ferrous material is a mixture of one or more of sulfuric acid slag, non-ferrous metal slag, copper slag, lead-zinc slag and manganese slag. The iron-aluminum material is a mixture of one or more of high-iron bauxite, low-grade bauxite and aluminum ore waste.

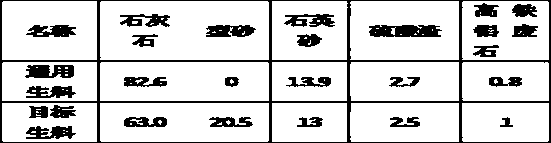

[0046] Further, as a more preferred embodiment, the following ratios are adopted:

[0047]

[0048] Table 4

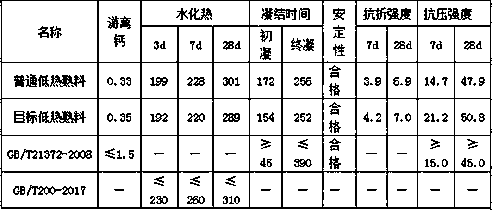

[0049]

[0050] table 5

[0051] From the above comparison results, it can be seen that the hydration heat value ...

Embodiment 2

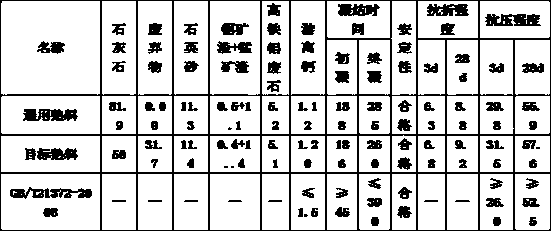

[0053] Further as a preferred embodiment, the following ratio is adopted in the present embodiment:

[0054]

[0055] Table 6

Embodiment 3

[0057] Further as a preferred embodiment, the present embodiment adopts the following ratios:

[0058]

[0059] Table 7

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com