Refractory material

A technology for refractory materials and auxiliary materials, applied in the field of non-burning refractory materials and materials, can solve the problems of unfavorable environmental protection and high cost of refractory materials, and achieve the effects of reducing the release of harmful substances, good bonding effect and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

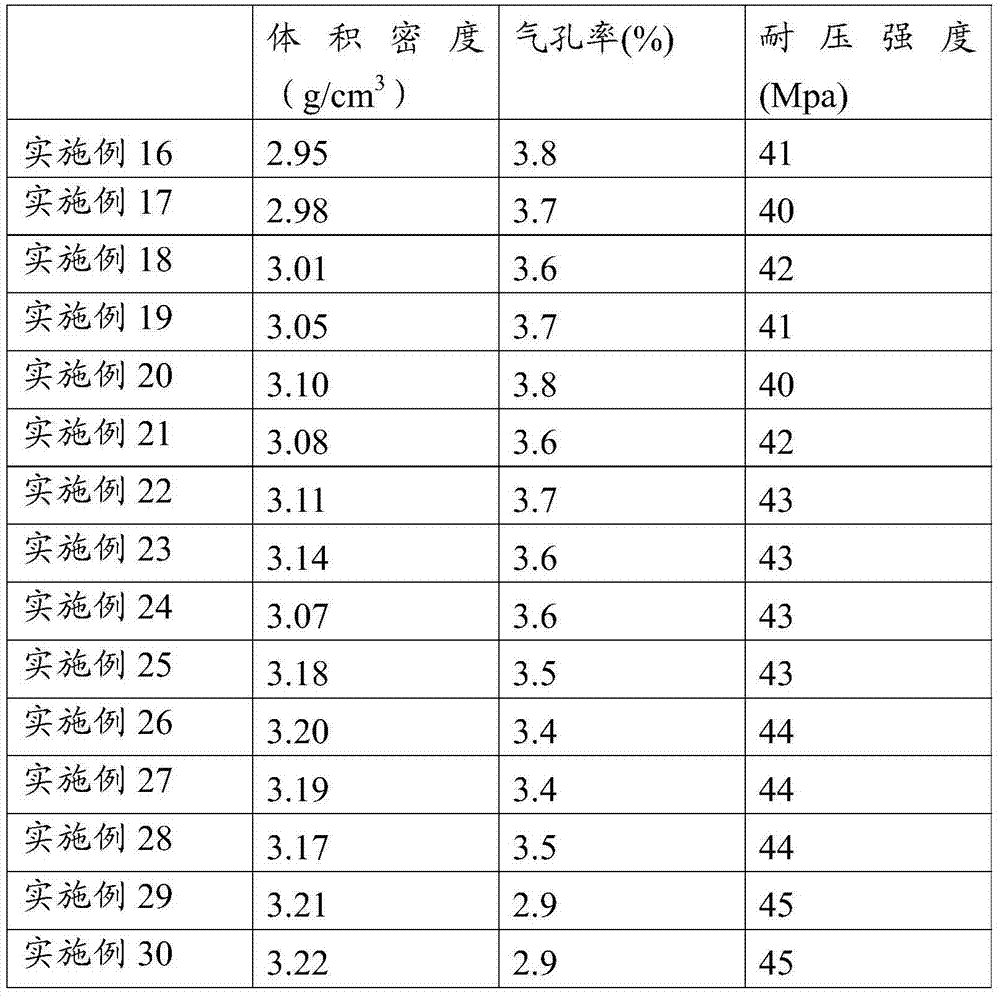

Examples

preparation example Construction

[0043] The invention also provides a method for preparing a refractory material, which is prepared by mixing the main refractory material and auxiliary materials;

[0044] The auxiliary material includes a lignin-sugar composition;

[0045] The lignin-sugar composition comprises lignosulfonate and sugars;

[0046] The sugar is selected from one or more of monosaccharides, disaccharides, oligosaccharides and sugar alcohols;

[0047] The mass ratio of the lignosulfonate to sugar is (10-90):(90:10).

[0048] The present invention does not limit the mixing method of the main material and auxiliary material of the refractory material, and the mixing method known to those skilled in the art is sufficient. The mixing temperature is preferably 0-100°C, more preferably 10-80°C, and most preferably 20 to 60°C, most preferably 30 to 55°C. The compositions and proportions of the main and auxiliary materials of the refractory material in the present invention have been clearly defined a...

Embodiment 1

[0068] 90 g of xylose and 10 g of sodium lignosulfonate were mixed at 30° C. to obtain a lignin-sugar composition.

Embodiment 2

[0070] Mix 10 g of cane sugar, 90 g of magnesium lignosulfonate, and 5 g of ethylene glycol at 40° C. to obtain a lignin-sugar composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com