Metal sealing ring for end part of oil pipe hanger, and sealing device

A metal sealing ring and tubing hanger technology, which is applied in sealing/package, engine sealing, wellbore/well parts, etc., can solve the problem that the reliability of the metal seal cannot be judged, installation and disassembly require special tools, and rubber seals Can not be used for a long time, to achieve the effect of saving installation and debugging time, small space, easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

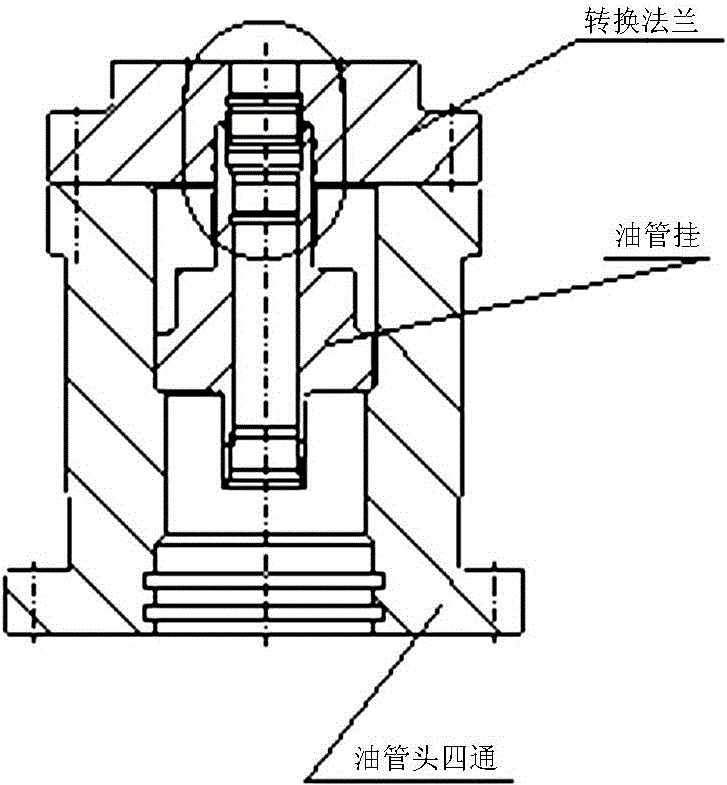

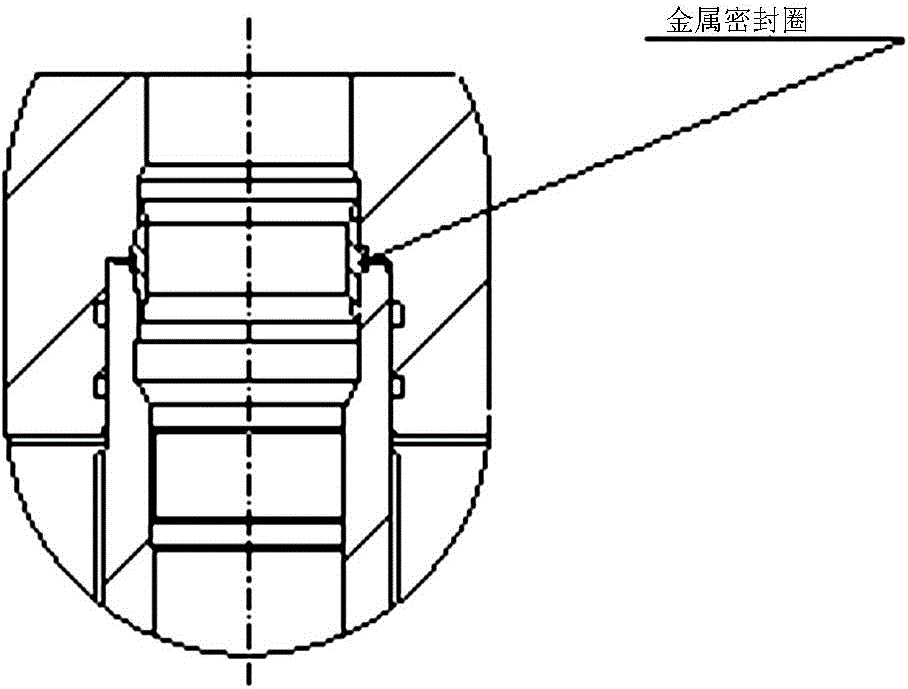

[0035] see Figure 4 , a metal sealing ring used at the end of a tubing hanger, comprising an eyelet body 1, the longitudinal section of the eyelet body is diamond-shaped, and the inner wall of the eyelet body 1 is sequentially provided with annular first stress relief from top to bottom The groove 3.1 and the first annular deformation groove 4.1; the outer wall of the metal ring body is sequentially provided with an annular second stress relief groove 3.2 and an annular second deformation groove 4.2 from bottom to top; the cross section of the stress relief groove is triangular, The section of the deformation groove is arc-shaped.

Embodiment 2

[0037] see Figure 5 , a sealing device composed of the metal seal ring used for the end of the tubing hanger in Embodiment 1, including an upper support ring 5, a lower support ring 6 and a metal seal ring, and the upper support ring 5 and the lower support ring 6 are respectively arranged On the top and bottom surfaces of the metal sealing ring; the bottom surface of the upper support ring 5 is an inclined plane, which is in contact with the top corner of the metal body 1 and has an angle difference; the top surface of the lower support ring 6 is an inclined plane, which is in contact with the metal ring body The bottom corners of 1 touch and have an angle difference of 8.

[0038] It works as follows:

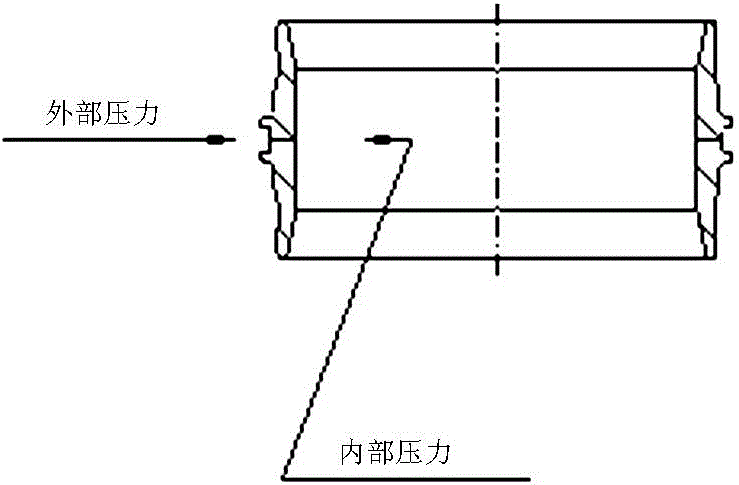

[0039] Such as Figure 5 As shown, the cross-section of the metal sealing ring body is rhombus-shaped, and the two diagonal corners of the rhombus-shaped cross-section are used as the contact points of the metal-to-metal seal (that is, the contact point 7 in the figure), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com