Deep-drawn-grade Ti-IF cold-rolled steel plate and preparation method thereof

A technology of cold-rolled steel sheet and deep-drawing grade, which is applied in the field of deep-drawing Ti-IF cold-rolled steel sheet and its preparation, can solve the problems of influence, unfavorable steel sheet performance, residual stress of steel sheet, etc., and achieve low yield ratio, good The effect of high plasticity and plastic strain ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

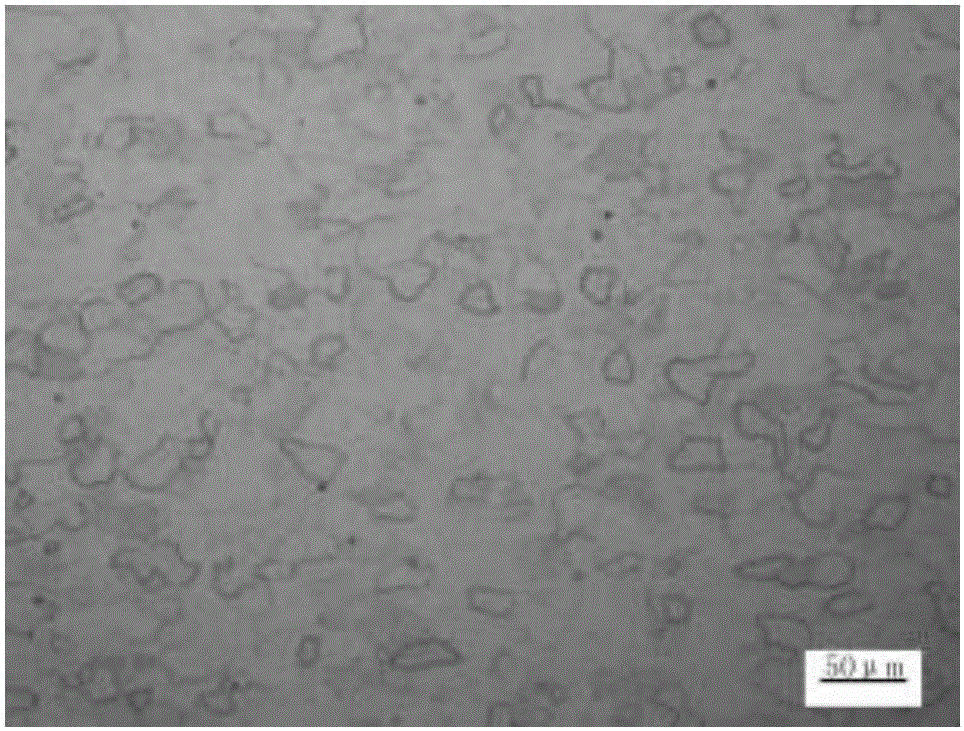

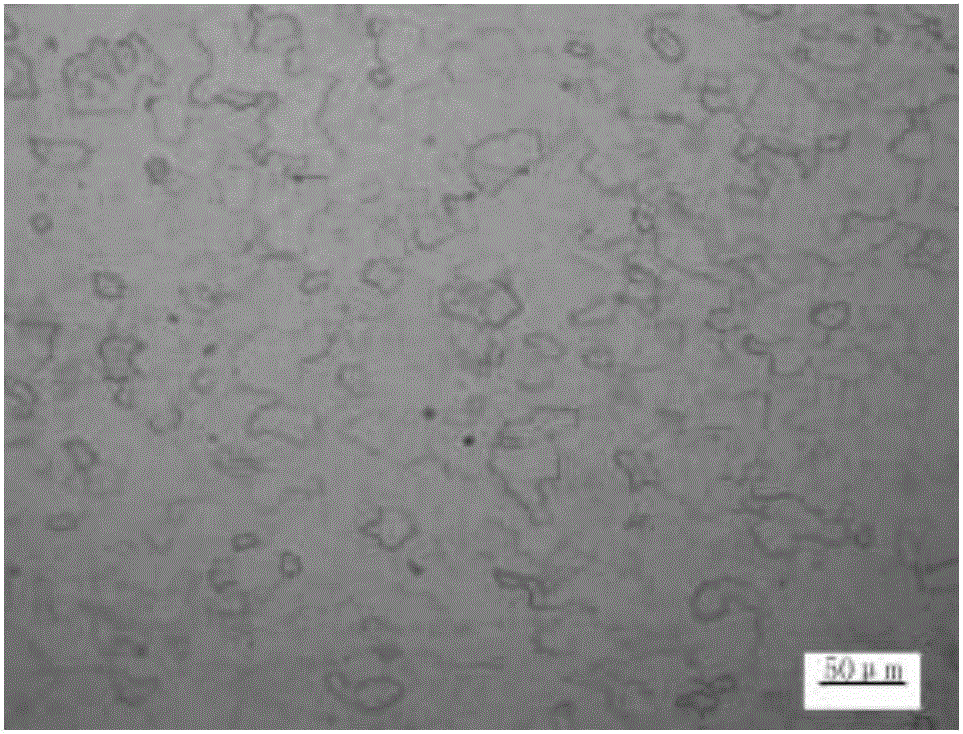

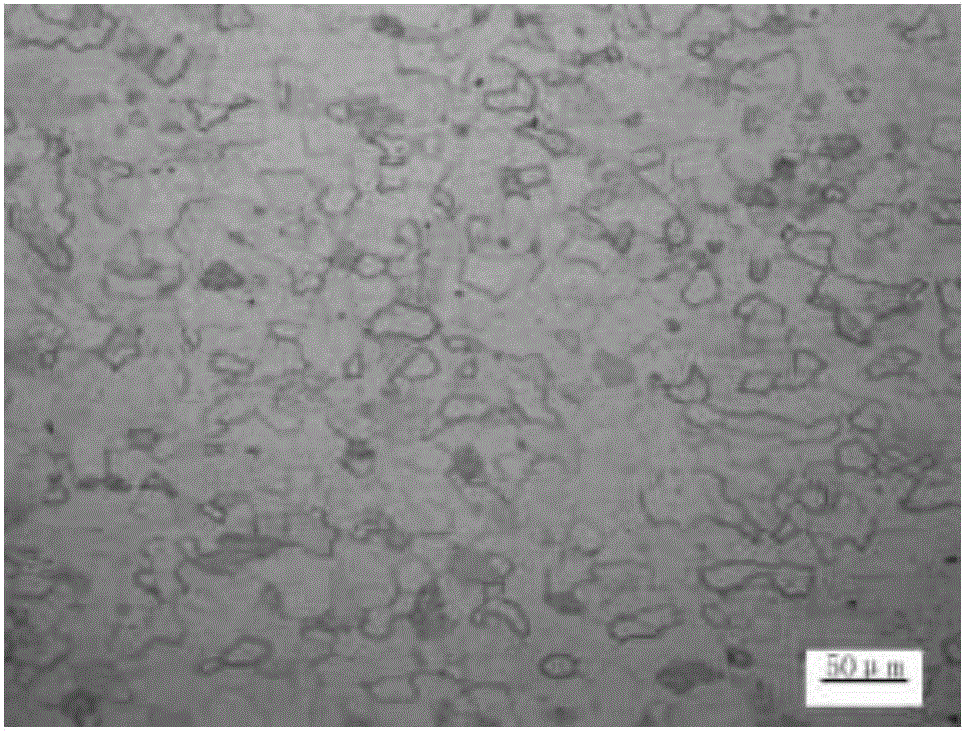

Image

Examples

preparation example Construction

[0028] The preparation method of deep-drawing grade Ti-IF cold-rolled steel plate specifically comprises the following steps:

[0029] Step 1: smelting and continuous casting;

[0030] Hot metal pretreatment, converter smelting, RH furnace refining, casting machine continuous casting. Steelmaking process control [O] ≤ 20ppm, [N] ≤ 30ppm, molten steel composition for casting machine is C: 0.001-0.003%, Si: 0.004-0.006%, Mn: 0.14-0.16, P: ≤ 0.010%, S ≤ 0.006%, Ti: 0.055-0.075%.

[0031] Step 2: Slab heating;

[0032] The heating process is strictly controlled within the furnace time, and the furnace temperature is 1210±15°C.

[0033] Step 3: Rolling;

[0034] Including rough rolling and finishing rolling, rough rolling adopts 2-stand rolling mill for rough rolling, and finish rolling adopts 7-stand continuous variable crown (Continuously variable crown, cvc) rolling mill for finishing rolling. The start rolling temperature of finish rolling is 1050±15°C, and the finish roll...

Embodiment 1

[0042]The molten iron is subjected to desulfurization pretreatment, and the top-bottom combined blowing converter is used to smelt the molten iron to decarburize and dephosphorize the molten steel to obtain molten steel, and the scrap steel is added to the converter. Then the molten steel after converter smelting is subjected to RH operation, and the in-situ temperature is 1630-1660°C, and deep decarburization treatment is carried out, the target is 20ppm. After the decarburization is completed, aluminum particles are added for deoxidation according to the fixed oxygen situation, and alloys such as titanium and iron are added to adjust the composition. , to ensure [O] in molten steel ≤ 20ppm. Smelting according to the chemical composition shown in Table 1, the superheat of slab continuous casting is 25°C, and the continuous casting process should use carbon-free tundish covering agent to avoid carbon increase in the casting process. After that, slab cleaning, slow cooling, and...

Embodiment 2

[0044] The molten iron is subjected to desulfurization pretreatment, and the top-bottom combined blowing converter is used to smelt the molten iron to decarburize and dephosphorize the molten steel to obtain molten steel, and the scrap steel is added to the converter. Then the molten steel after converter smelting is subjected to RH operation, and the in-situ temperature is 1630-1660°C, and deep decarburization treatment is carried out, the target is 20ppm. After the decarburization is completed, aluminum particles are added for deoxidation according to the fixed oxygen situation, and alloys such as titanium and iron are added to adjust the composition. , to ensure [O] in molten steel ≤ 20ppm. Smelting according to the chemical composition shown in Table 1, the superheat of slab continuous casting is 25°C, and the continuous casting process should use carbon-free tundish covering agent to avoid carbon increase in the casting process. After that, slab cleaning, slow cooling, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com