Method for preparing large nanocrystalline magnesium alloy through small deformation

A magnesium alloy and nanocrystalline technology, which is applied in the field of preparation of new nanocrystalline materials, can solve problems such as cracking, unobvious mechanical properties, and poor surface quality of magnesium alloy plates, so as to reduce recrystallization temperature, inhibit grain growth, The effect of suppressing the growth of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

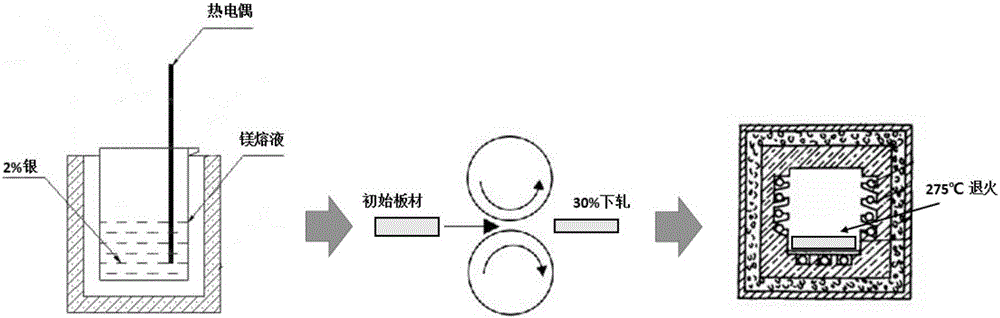

[0027] Such as figure 1 As shown, the following embodiments involve a three-step process including: alloy smelting, room temperature rolling and low temperature short-term heat treatment, wherein:

[0028] In the smelting process of the magnesium alloy, 5% by weight of Ag particles is added, and the addition temperature is 720° C., and at (both volume ratio) 98% CO 2 +2% SF 6 Fully stir the magnesium melt under the smelting protective atmosphere and cast it after standing for 15 minutes. The casting temperature of the alloy is 700°C, and the preheating temperature of the metal mold used for casting is 200°C. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com