Cold-rolled low-temperature acid dew point corrosion resistant steel and manufacturing method thereof

A manufacturing method and acid dew point technology, which are applied to cold-rolled low-temperature acid dew point corrosion-resistant steel and its manufacturing field, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Chemical composition (wt%): C: 0.086, Si: 0.30, Mn: 0.48, S: 0.006, Cu: 0.26, Cr: 0.97, Mo: 0.09, Sb: 0.079.

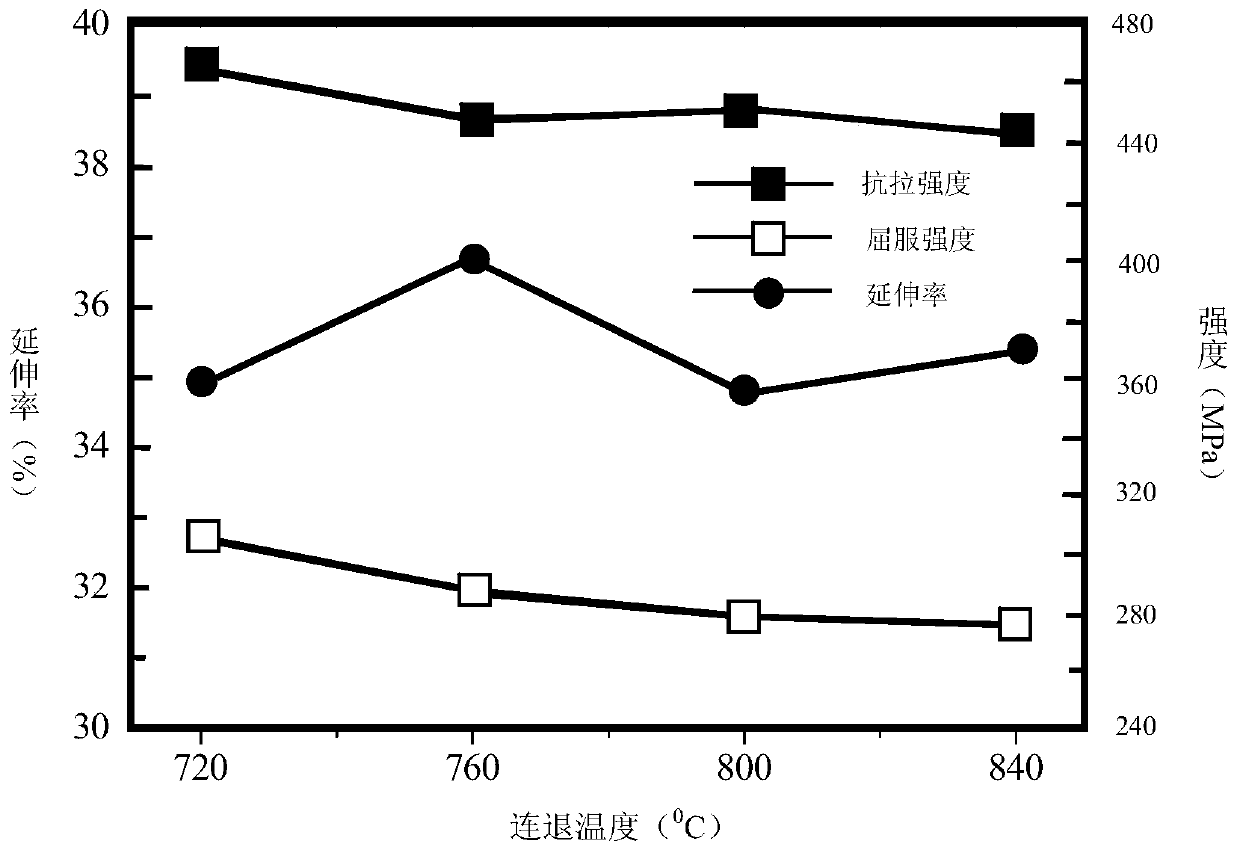

[0067] Manufacturing method: billet hot rolling heating temperature 1230°C, finish rolling temperature 880°C, coiling temperature 660°C, cold rolling reduction rate 50%, continuous annealing temperature 800°C, holding time 90s, smoothing rate 1.2%.

[0068] Microstructure: ferrite + pearlite, pearlite content is about 10%, such as Figure 5 As shown, granular cementite is distributed at the ferrite phase boundary.

[0069] Mechanical properties: Yield strength 289MPa, tensile strength 451MPa, elongation 38.3%.

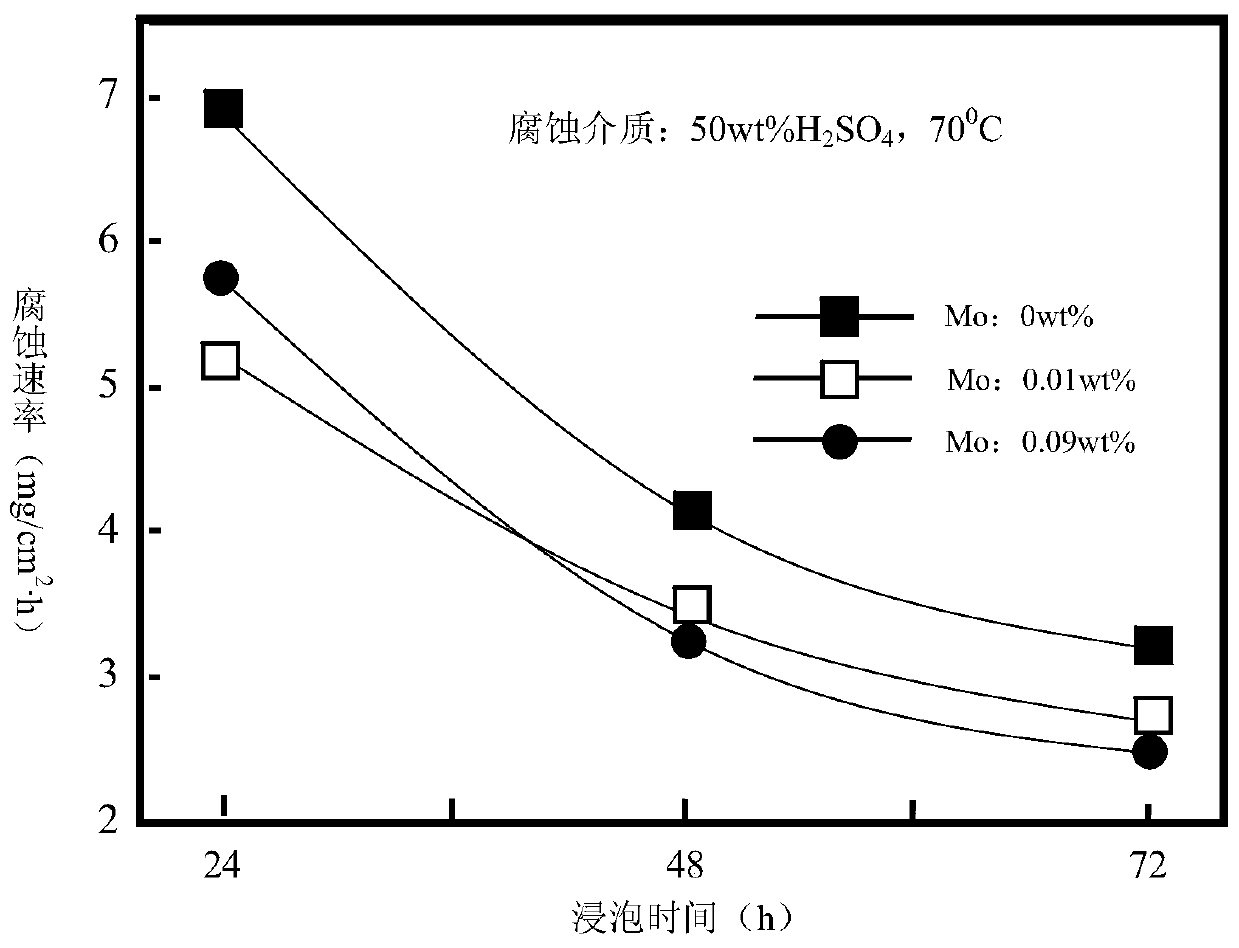

[0070] At 70°C, 50wt.%H 2 SO 4 Soaked for 24 hours, sulfuric acid corrosion resistance rate: 5.73mg / cm 2 h.

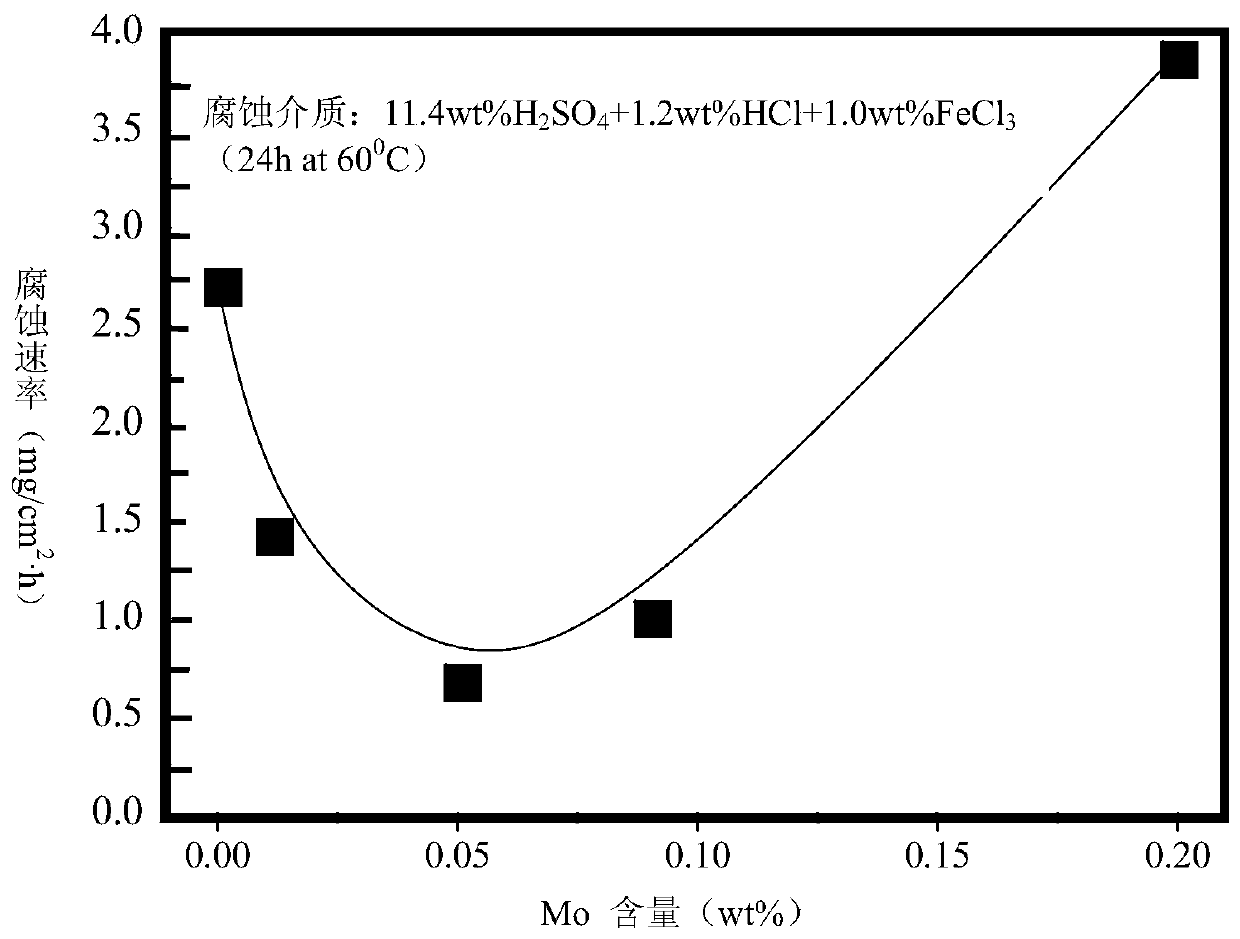

[0071] At 60°C, 11.4wt.%H 2 SO 4 +1.2wt.%HCl+1.0wt.%FeCl 3 Soaked for 24 hours, mixed acid corrosion resistance rate: 1.02mg / cm 2 h.

[0072] According to SEM and EDS analysis, there are Cu and Sb oxides in the surface corrosion layer,...

Embodiment 2

[0075] Chemical composition (wt%): C: 0.076, Si: 0.31, Mn: 0.44, S: 0.008, Cu: 0.24, Cr: 0.94, Mo: 0.05, Sb: 0.077.

[0076]Manufacturing method: Billet heating temperature during hot rolling is 1220°C, final rolling temperature is 920°C, coiling temperature is 640°C, cold rolling reduction rate is 66.7%, continuous annealing temperature is 760°C, holding time is 95s, and smoothing rate is 1.4%.

[0077] Microstructure: ferrite + pearlite, pearlite content is about 10%.

[0078] Mechanical properties: Yield strength 283MPa, tensile strength 445MPa, elongation 36.5%.

[0079] At 70°C, 50wt.%H 2 SO 4 Soaked for 24 hours, sulfuric acid corrosion resistance rate: 5.53mg / cm 2 h.

[0080] At 60°C, 11.4wt.%H 2 SO 4 +1.2wt.%HCl+1.0wt.%FeCl 3 Soaked for 24 hours, mixed acid corrosion resistance rate: 0.67mg / cm 2 h.

Embodiment 3

[0082] Chemical composition (wt%): C: 0.053, Si: 0.27, Mn: 0.59, S: 0.015, Cu: 0.35, Cr: 0.86, Mo: 0.03, Sb: 0.067.

[0083] Manufacturing method: The billet heating temperature is 1200°C during hot rolling, the final rolling temperature is 860°C, the coiling temperature is 620°C, the cold rolling reduction rate is 75%, the continuous annealing temperature is 740°C, the holding time is 110s, and the smoothing rate is 0.8%.

[0084] Microstructure: ferrite + pearlite, pearlite content is about 10%.

[0085] Mechanical properties: Yield strength 273MPa, tensile strength 431MPa, elongation 37%.

[0086] At 70°C, 50wt.%H 2 SO 4 Soaked for 24 hours, sulfuric acid corrosion resistance rate: 5.31mg / cm 2 h.

[0087] At 60°C, 11.4wt.%H 2 SO 4 +1.2wt.%HCl+1.0wt.%FeCl 3 Soaked for 24 hours, mixed acid corrosion resistance rate: 0.97mg / cm 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com