High-strength corrosion-resistant aluminum alloy for variable-diameter drill pipe body and manufacturing method of aluminium alloy

A manufacturing method and technology of drill pipe, which is applied in the field of hot extrusion manufacturing, can solve the problems of untested corrosion resistance and fatigue resistance, and achieve the effects of hindering the recrystallization process, high strength, and improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A high-strength corrosion-resistant aluminum alloy for a variable-diameter drill pipe body, the chemical composition is calculated by weight percentage, including: Zn: 6%, Mg: 2.8%, Cu: 0.7%, Fe: 0.15%, Zr: 0.05%, Ti: 0.02%, Mn: 0.2%, Cr: 0.15%, and the balance is Al and unavoidable impurities.

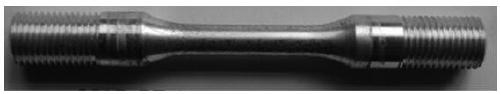

[0046] The manufacturing method of the pipe body for the above-mentioned variable-diameter drill pipe is as follows: cast the above-mentioned raw materials into a round cast rod; under the condition of a heating rate of 10°C / min, heat the round cast rod to 340°C, keep it warm for 10h, and finally heat it to 450°C ℃, heat preservation for 32h, and then naturally lowered to room temperature to obtain a homogenized round cast rod; according to the A-level flaw detection requirements in GB / T 6519, 100% of the round rod is subjected to ultrasonic flaw detection; the round rod is turned, bored, Obtain a round hollow rod; heat the round hollow rod to 400°C for variable cross-section e...

Embodiment 2

[0055] A high-strength corrosion-resistant aluminum alloy for a variable-diameter drill pipe body, the chemical composition is calculated by weight percentage, including: Zn: 6.3%, Mg: 2.5%, Cu: 0.5%, Fe: 0.1%, Zr: 0.10%, Ti: 0.04%, Mn: 0.3%, Cr: 0.25%, and the balance is Al and unavoidable impurities.

[0056] The manufacturing method of the above-mentioned aluminum alloy drill pipe body is as follows: casting the above-mentioned raw materials into a round cast rod; under the condition of a heating rate of 15°C / min, heating the round cast rod to 365°C, holding it for 8.5h, and finally heating to 465°C, keep warm for 28 hours, then cool down to room temperature naturally, and obtain round cast rods that have been homogenized; according to the A-level flaw detection requirements in GB / T 6519, 100% of the round rods are subjected to ultrasonic flaw detection; the round rods are turned and bored , to get a round hollow rod; heat the round hollow rod to 410°C, and carry out variab...

Embodiment 3

[0064] A high-strength corrosion-resistant aluminum alloy for a variable-diameter drill pipe body, the chemical composition is calculated by weight percentage, including: Zn: 5.5%, Mg: 3.1%, Cu: 0.9%, Fe: 0.15%, Zr: 0.05%, Ti: 0.06%, Mn: 0.1%, Cr: 0.1%, and the balance is Al and unavoidable impurities.

[0065] The manufacturing method of the above-mentioned aluminum alloy drill pipe body is as follows: casting the above-mentioned raw materials into a round cast rod; under the condition of a heating rate of 18°C / min, heating the round cast rod to 360°C, holding it for 8.5h, and finally heating to 460°C, keep warm for 25h, then cool down to room temperature naturally to obtain round cast rods that have been homogenized; according to the A-level flaw detection requirements in GB / T 6519, 100% of the round rods are subjected to ultrasonic flaw detection; the round rods are turned and bored , to obtain a round hollow rod; heat the round hollow rod to 395°C, and carry out variable c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com