Carbon structural steel plate and preparation method thereof

A carbon structure and steel plate technology, applied in the field of carbon structural steel plate and its preparation, can solve the problems of low formability of carbon structural steel and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

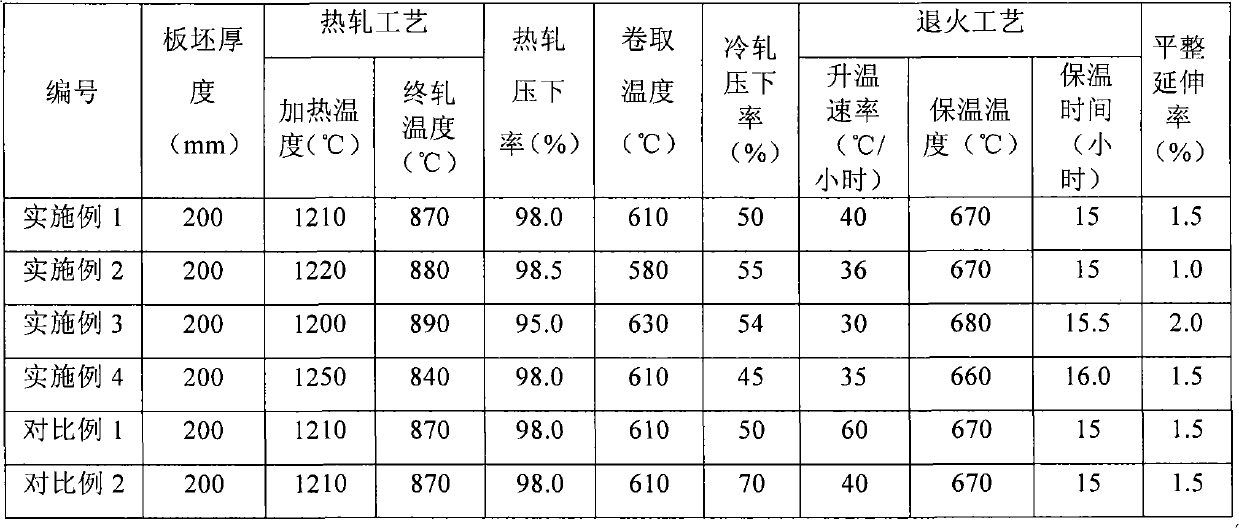

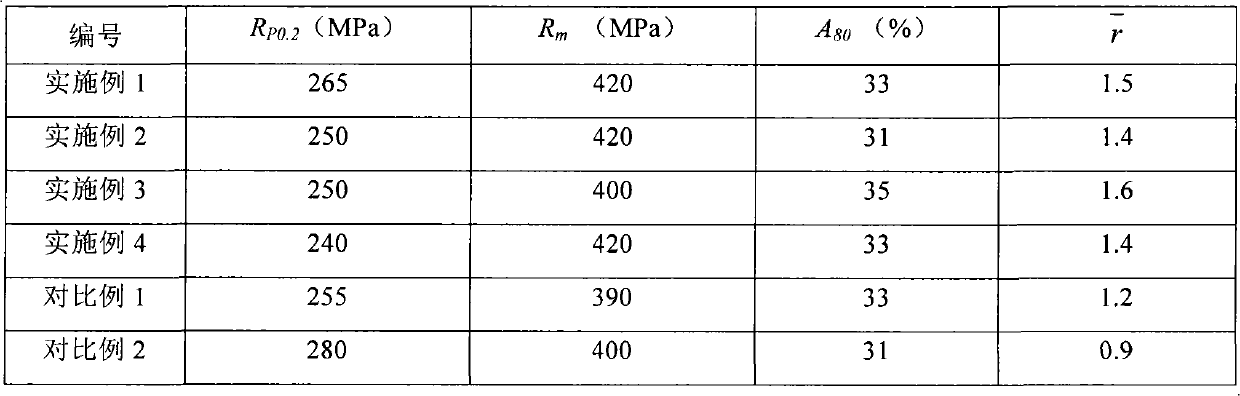

[0018] According to the method for preparing a carbon structural steel plate of the present invention, the method comprises preparing a steel slab, and performing hot rolling, coiling, cold rolling and annealing the steel slab obtained above in sequence, wherein the cold rolling reduction rate can be 40-60 %, preferably 45-55%; the annealing temperature can be 650-700°C, preferably 660-680°C; the annealing temperature rise rate between 450°C and annealing temperature can be 30-45°C / hour, preferably 30- 40°C / hour. The carbon structural steel plate prepared under the above conditions has good yield strength, tensile strength and elongation after fracture, and the plastic strain ratio of the carbon structural steel plate is weighted average ( value) is high and has good formability.

[0019]The method for preparing a steel slab generally includes two steps of smelting and casting. In the smelting stage, the composition of the molten steel is adjusted to be consistent with the ...

Embodiment 1-4

[0030] This embodiment is used to illustrate the carbon structural steel plate provided by the present invention and its preparation method.

[0031] The steel slab with the chemical composition shown in Table 1 prepared by the method for continuous casting is used as raw material; The continuous casting slab made is coiled after heating, hot rolling and cooling on the hot continuous rolling mill; the prepared After the hot-rolled coils are cooled to room temperature, pickling is carried out, and then cold-rolled coils are produced on the combined cold continuous rolling mill (CDCM unit). Annealing. After cooling to room temperature, the annealed cold-rolled steel plate is tempered on a single-stand tempering unit. The main parameters of the preparation process are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com