Method for preparing recrystallized silica carbide porous ceramic with gas-solid reaction method

A gas-solid reaction, porous ceramic technology, used in ceramic products, applications, household appliances, etc., can solve the problems of high cost and high sintering temperature of recrystallized silicon carbide, and achieve the effects of improving strength, saving energy and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific examples.

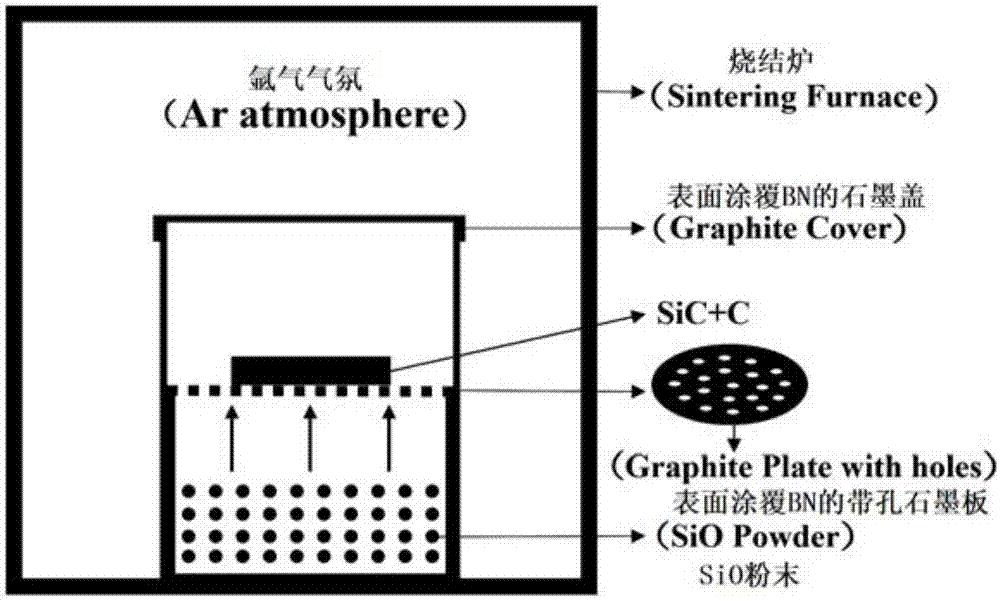

[0022] The composition of the silicon carbide porous ceramics of the present invention is shown in Table 1. In Examples 1 to 12 shown in Table 1, micron silicon carbide acts as a skeleton in the green body, and as coarse particles in the recrystallization process, nanometer Carbon black acts as a carbon source for gas-solid reaction, silicon monoxide acts as a silicon source for gas-solid reaction, and nano-silicon carbide synthesized by gas-solid reaction acts as fine particles in the recrystallization process.

[0023] Table 1. The raw material composition of silicon carbide porous ceramics of the present invention

[0024]

[0025] Table 2. The sintering process parameters of silicon carbide porous ceramics of the present invention

[0026]

[0027]

[0028] The embodiment in Table 1 is the preparation method of silicon carbide porous ceramics. First, si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com