A rivetable deformable low-copper alloy material and its application

A copper alloy and riveting technology, applied in contact parts and other directions, can solve the problems of less than 25%, high position, shortage of copper resources, etc., and achieve the effect of cost saving and good deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

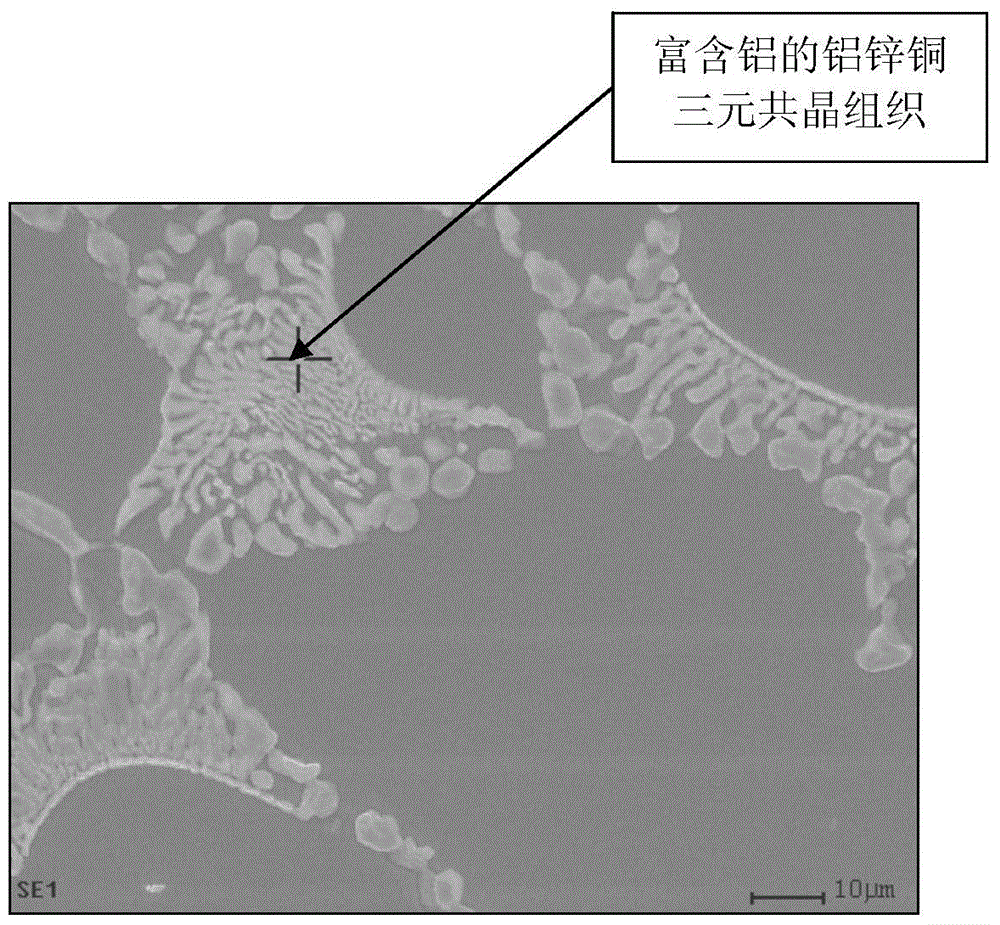

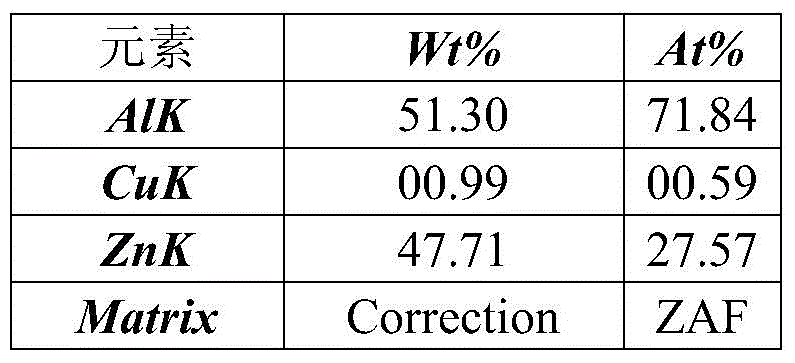

[0033] The SEM picture of embodiment 1 low-copper alloy microstructure is as figure 1 as shown, figure 1 The energy spectrum analysis results indicated by the middle arrow are as follows figure 2 As shown, it can be clearly seen that the alloy of the present invention has an aluminum-rich Al-Zn-Cu ternary eutectic structure, and the ternary eutectic structure is a network.

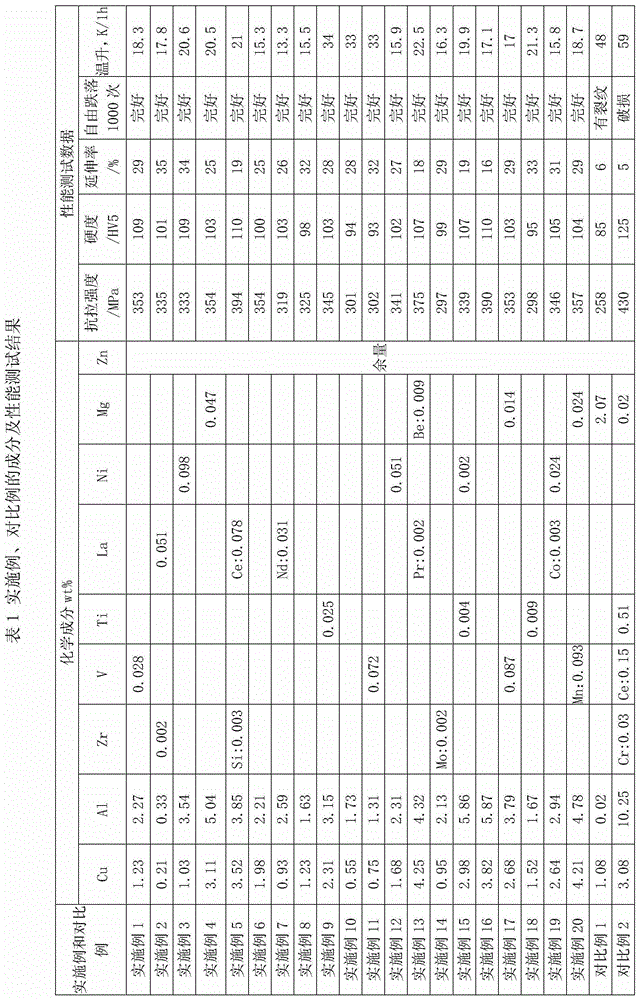

[0034] According to the IEC60884-1 standard, the free drop and temperature rise test is carried out. The IEC60884-1 standard stipulates that the finished plug is energized with AC for 1 hour, and the temperature rise cannot exceed 45K. 100-1000 times of drum drop test, the plug must not be broken or bent during the test. Free fall and temperature rise tests were performed on the examples and comparative alloys. The sample in the free drop test does not have a flexible cable, and the weight does not exceed 100g. After falling 1000 times, observe whether there are cracks on the surface of the sample to j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com