Low-anisotropic-index high-intensity Cu-Ni-Si alloy and preparing process thereof

A cu-ni-si, anisotropic technology, used in cold-rolled sheet materials for lead frames, low anisotropy index high-strength Cu-Ni-Si alloys and their preparation fields, can solve the problem of reduced bending performance, sheet metal Problems such as aggravation of anisotropic behavior, to achieve the effect of reducing anisotropy, less equipment requirements, and reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A low anisotropy index high-strength Cu-Ni-Si alloy, its components are shown in Table 1:

[0050] The chemical composition (wt%) of Cu-Ni-Si alloy in the embodiment 1 of table 1

[0051] Ni

Si

Mg

Zn

sn

Fe

RE

Cu

3.12

0.72

0.226

0.06

0.51

0.076

0.3

margin

[0052] A preparation process of a low anisotropy index high-strength Cu-Ni-Si alloy, comprising the steps of:

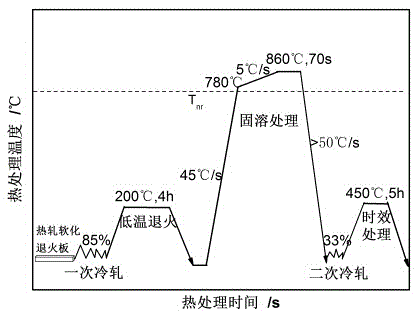

[0053] (1) Smelting and casting is carried out according to the composition in Table 1, and the smelting is carried out in an intermediate frequency induction furnace, and the size of the ingot is 120×100×25mm. The cast slab is heated to 930°C for 2 hours, and hot rolled on a two-roller hot rolling mill. The starting temperature of the hot rolling is 920°C, rolling 10 passes, the final plate thickness is 5mm, and the final rolling temperature is 780°C. Immediately after the rolling is completed, the water-cooled hot-rolled plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com