Processing method for producing low-cost high-formability IF (interstitial-free) steel

A processing method and formability technology, applied in metal rolling, temperature control, etc., can solve problems such as finishing rolling easily falling into the two-phase region, and achieve the effects of low cost, high production efficiency, and high product formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

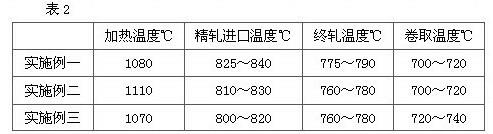

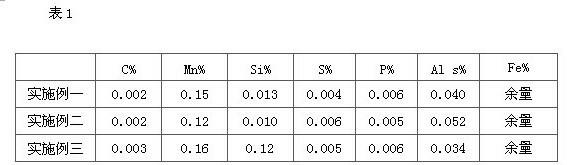

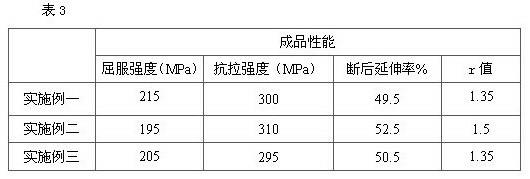

Embodiment 1

[0030] Example 1, the steel factory refines qualified molten steel, and continuously casts it into a slab of 70*1270mm. The mass percentage of the chemical composition is C: 0.002%, Si: 0.013%, Mn: 0.15%, P: 0.006%, S: 0.004%, Al : 0.040%, the balance is Fe; the continuous casting slab is heated to 1080°C, and after the billet comes out of the furnace, it enters two rough rolling mills. , the final rolling temperature is 775-790°C, and the thickness of the finished product is 4.0mm. After finishing rolling, it enters laminar flow cooling, and then cools to 700-720°C for coiling. After coiling, it is pile-cooled and air-cooled, and then naturally cooled to room temperature. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties of the rolled material are listed in Table 3.

Embodiment 2

[0031] Example 2: Steel mills refine qualified molten steel and continuously cast it into a slab of 70*1270mm. The mass percentages of chemical components are C:0.002%, Si:0.010%, Mn:0.12%, P:0.005%, S:0.006%, Al : 0.052%, the balance is Fe; the continuous casting slab is heated to 1110°C, and after the billet comes out of the furnace, it enters 2 rough rolling mills. , the final rolling temperature is 760-780°C, and the thickness of the finished product is 4.0mm. After finishing rolling, enter laminar flow cooling, cool to 700-720°C for coiling, stack cooling and air cooling after coiling, and naturally cool to room temperature. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties of the rolled material are listed in Table 3.

Embodiment 3

[0032]Example 3: Steel mills refine qualified molten steel and continuously cast it into 70*1270mm slabs. The mass percentages of chemical components are C: 0.003%, Si: 0.12%, Mn: 0.16%, P: 0.006%, S: 0.005%, Al : 0.034%, the balance is Fe; the continuous casting slab is heated to 1070°C, and after the billet comes out of the furnace, it enters 2 rough rolling mills. Rolling, the final rolling temperature is 760-780°C, and the thickness of the finished product is 3.5mm. After finishing rolling, it enters laminar cooling and air-cools to 720-740°C for coiling. The chemical composition is listed in Table 1, the process parameters are listed in Table 2, and the mechanical properties of the rolled material are listed in Table 3.

[0033]

[0034]

[0035]

[0036] The invention adopts a ferrite rolling process to produce high formability IF steel based on the thin slab continuous casting and rolling process, and has the advantages of simple process, low cost, high product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com