Rolled aluminum-copper composite board with high peeling strength and preparation method of composite board

A technology of aluminum-copper composite board and rolling composite, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the influence of aluminum-copper composite board interface shear strength and peel strength, copper strip heating temperature Impossible to be very high, oxidation coloring temperature is low, etc., to achieve the effect of improving peel strength, reducing deformation resistance, and simplifying production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

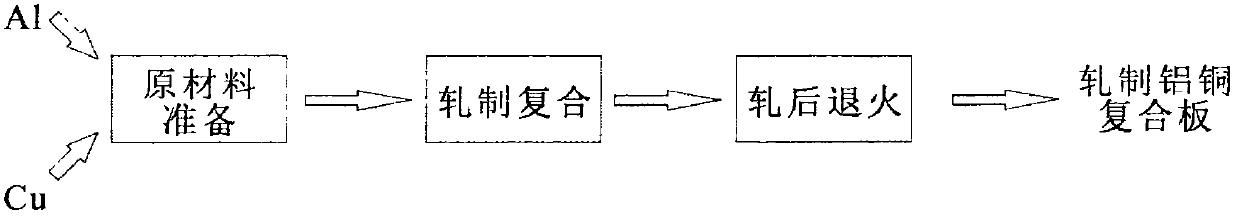

Image

Examples

Embodiment 1

[0025] (1) Raw material preparation: first cut the industrial 1060 pure aluminum plate with a thickness of 5mm and the industrial TU2 pure copper plate with a thickness of 40mm into aluminum and copper raw material plates with a width of 400mm and a length of 2400mm, and then cut the two raw material plates Carry out annealing treatment, the temperature is 350 ℃ and 300 ℃ respectively, and the holding time is 45min and 30min respectively, and then take out and polish the surface to be combined to remove the surface oxide;

[0026] (2) Rolling and compounding: heat the surface-treated 1060 pure aluminum plate in a heat treatment furnace at a heating temperature of 280°C, take it out after 30 minutes of heat preservation, and roll and compound it with a TU2 pure copper plate at room temperature to form an aluminum-copper composite plate;

[0027] (3) Post-rolling annealing: put the rolled and composited aluminum-copper composite plate into an annealing furnace for annealing, the ...

Embodiment 2

[0029] (1) Raw material preparation: first cut the 10mm thick 6061 aluminum alloy plate and the 80mm thick industrial TU2 pure copper plate into aluminum and copper raw material plates with a width of 600mm and a length of 3000mm, and then cut the two raw material plates Annealing treatment, the temperature is 350°C and 300°C, and the holding time is 45min and 30min respectively, and then take out and polish the surface of the two to be combined to remove the surface oxide;

[0030] (2) Rolling and compounding: heat the surface-treated 6061 aluminum alloy plate in a heat treatment furnace at a temperature of 300°C, take it out after 30 minutes of heat preservation, and roll and compound it with a TU2 pure copper plate at room temperature to form an aluminum-copper composite plate ;

[0031] (3) Post-rolling annealing: Put the rolled and composited aluminum-copper composite plate into an annealing furnace for annealing. The annealing temperature is 210°C, and the temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com