Method for producing thin format hot rolled steel plate

A hot-rolled steel plate and production method technology, applied in the field of steel rolling, can solve problems such as the quality defects of the oxide scale on the surface of the steel strip, the large deformation of the rear frame, and the easy peeling of the oxide film on the surface of the roll, so as to improve the control ability of the plate shape, improve the Improve the surface quality of strip steel and realize the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

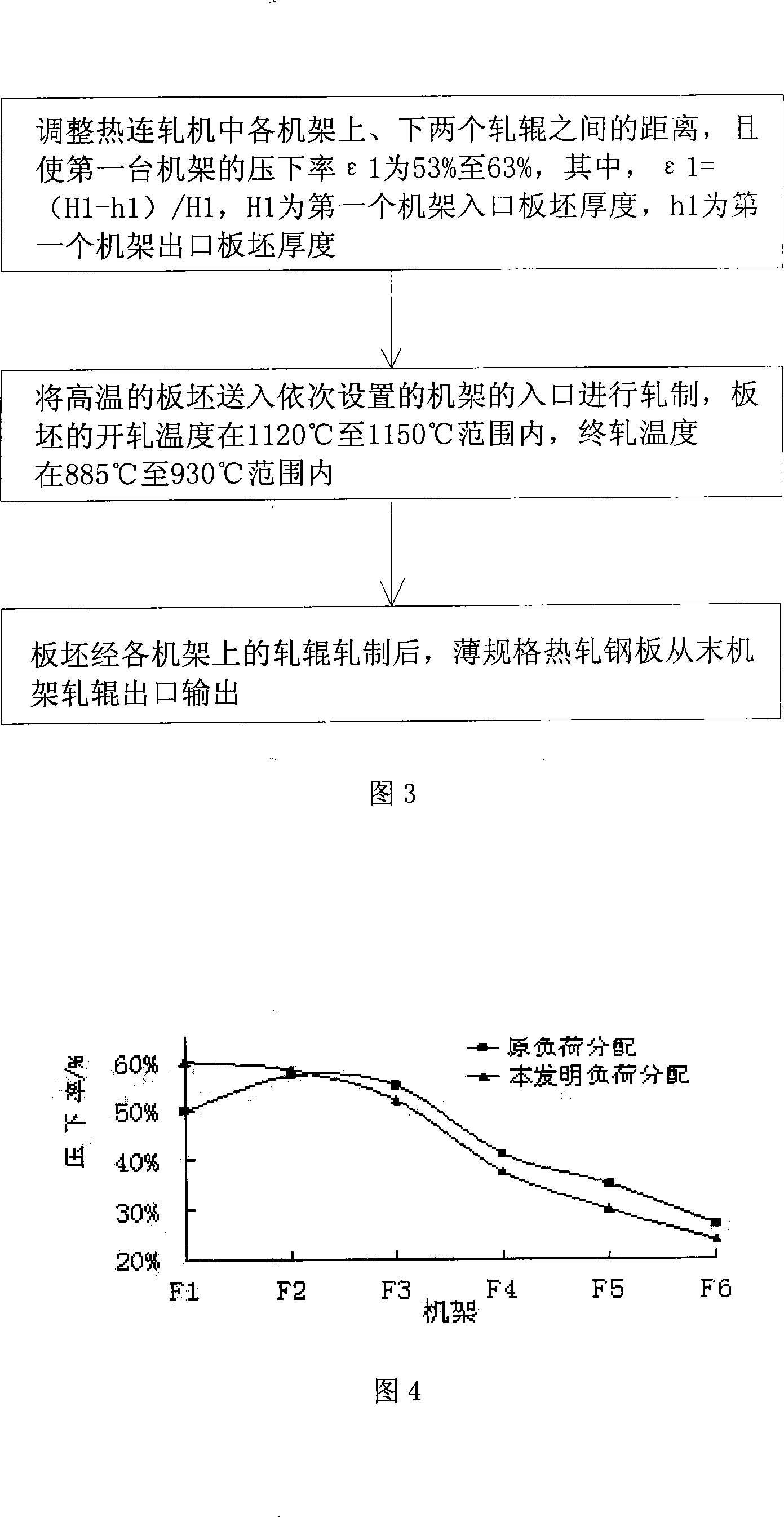

[0053] As shown in Figure 3, a kind of production method of thin-gauge hot-rolled steel plate, this method comprises the steps:

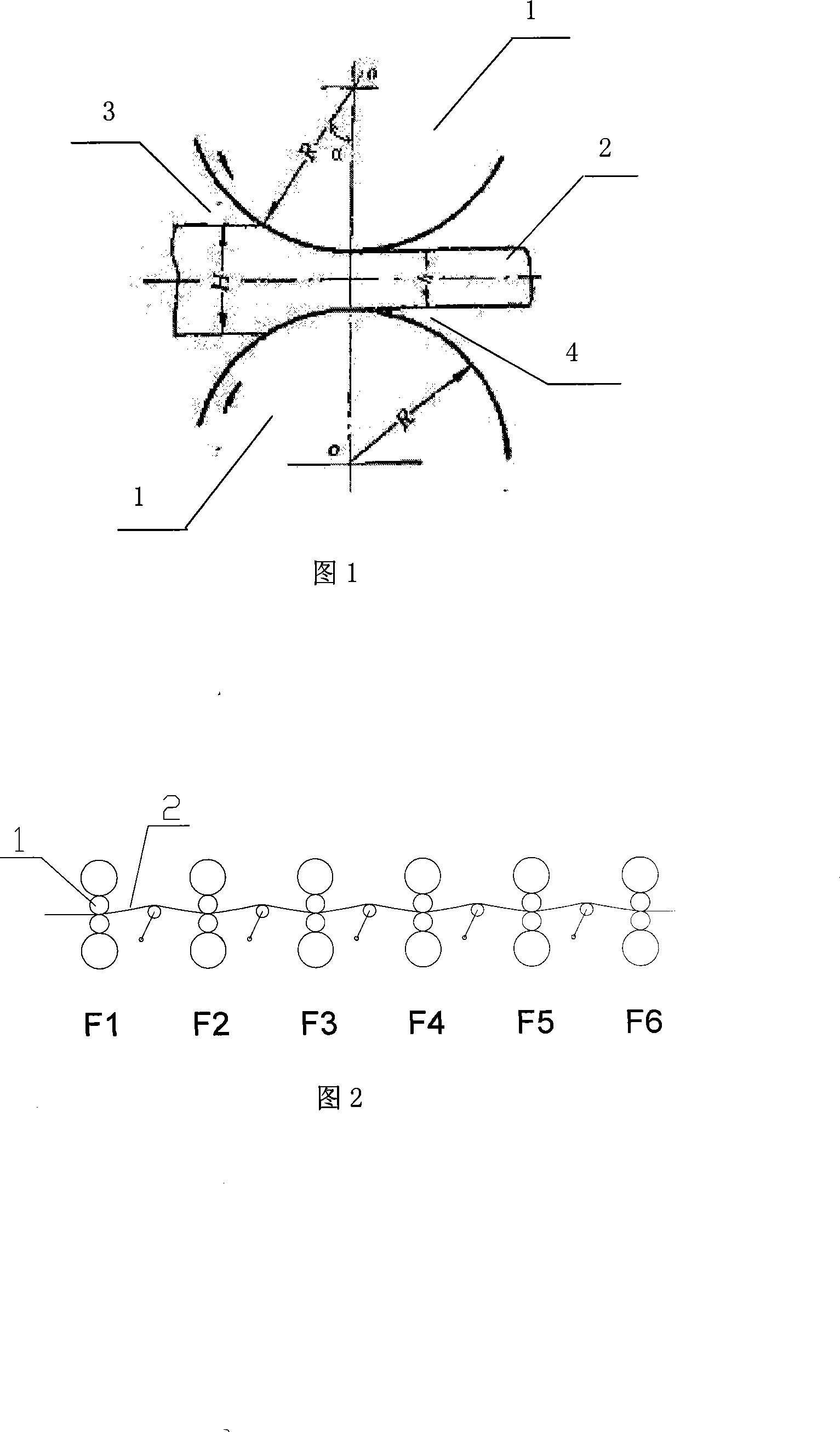

[0054]a, adjust the distance between the upper and lower two rolls 1 of each stand in the hot rolling mill, and make the reduction rate ε1 of the first stand be 53% to 63%, wherein, ε1=(H1-h1) / H1, H1 is the thickness of the slab at the entrance of the first rack, h1 is the thickness of the slab at the exit of the first rack;

[0055] b. Send the high-temperature slab 2 into the roll inlet 3 of the successively arranged racks for rolling;

[0056] c. After the slab 2 is rolled by the rolls 1 on each stand, the thin gauge hot-rolled steel plate is output from the roll outlet 4 .

[0057] As shown in Figure 2, when the reduction rate of the first stand F1 is increased, the load on the subsequent stands F2, F3, F4, F5, and F6 can be greatly reduced, which can improve the efficiency of the entire rolling process , and then the load on the stand is red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com