Non-quenched and non-tempered 980 MPa grade high-strength strapping steel and production method thereof

A production method, 980mpa technology, applied in the field of steel strip raw materials, can solve the problems of high energy consumption and high cost, complex equipment, environmental pollution and other problems in the production of high-strength strapping, and achieve the elimination of quenching and tempering process, reduce energy consumption and cost, and improve performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

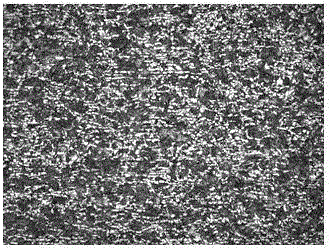

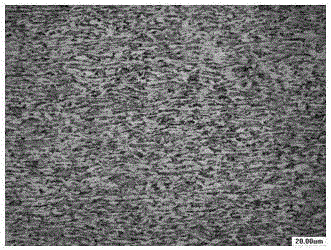

Image

Examples

Embodiment 1

[0023] Embodiment 1: The specific process of the non-quenched and tempered 980MPa grade high-strength strapping steel is as follows.

[0024] (1) Steelmaking process: The weight percentage of the chemical composition of the molten steel is: C 0.19%, Mn 1.23%, S 0.003%, P 0.017%, Si 0.03%, Als 0.025%, N 0.0037%, the rest is iron and non Avoid impurities.

[0025] (2) Heating process: the slab is heated to 1200±10°C.

[0026] (3) Hot rolling process: the starting temperature of the rough rolling of the slab is controlled at 1100±10°C; the starting temperature of the finish rolling is 1030±10°C, the final rolling temperature is 835±10°C, and the thickness of the rolled steel plate is 3.0mm.

[0027] (4) Cooling process: before the steel plate enters laminar flow cooling, the temperature is 815-830°C, cooled at 100°C / s to 700±10°C, air-cooled for 3s; continue to cool at 100°C / s to 430°C±10°C coiled. The mechanical properties of the obtained hot-rolled steel strip are tested, an...

Embodiment 2

[0029] Embodiment 2: The specific process of the non-quenched and tempered 980MPa grade high-strength strapping steel is as follows.

[0030] (1) Steelmaking process: The weight percentage of the chemical composition of the molten steel is: C 0.18%, Mn 1.26%, S 0.002%, P 0.017%, Si 0.09%, Als 0.030%, N 0.0034%, the rest is iron and non Avoid impurities.

[0031] (2) Heating process: the slab is heated to 1200±10°C.

[0032] (3) Hot rolling process: the starting temperature of the rough rolling of the slab is controlled at 1100±10°C; the starting temperature of the finish rolling is 1030±10°C, the final rolling temperature is 835±10°C, and the thickness of the rolled steel plate is 2.8mm.

[0033] (4) Cooling process: before the steel plate enters laminar flow cooling, the temperature is 815-830°C, cooled at 110°C / s to 700±10°C, air-cooled for 2s; continue to cool at 120°C / s to 430°C±10°C coiled. The mechanical properties of the obtained hot-rolled steel strip are tested, an...

Embodiment 3

[0035] Embodiment 3: The specific process of the non-quenched and tempered 980MPa grade high-strength strip steel is as follows.

[0036] (1) Steelmaking process: The weight percentage of the chemical composition of the molten steel is: C 0.17%, Mn 1.27%, S 0.003%, P 0.018%, Si 0.15%, Als 0.039%, N 0.0032%, the rest is iron and non Avoid impurities.

[0037] (2) Heating process: the slab is heated to 1200±10°C.

[0038] (3) Hot rolling process: the starting temperature of the rough rolling of the slab is controlled at 1100±10°C; the starting temperature of the finish rolling is 1030±10°C, the final rolling temperature is 830±10°C, and the thickness of the rolled steel plate is 3mm.

[0039] (4) Cooling process: before the steel plate enters laminar flow cooling, the temperature is 815-830°C, cooled at 110°C / s to 700±10°C, air-cooled for 2.2s; continue to cool at 120°C / s to 430°C±10°C Do coiling. The mechanical properties of the obtained hot-rolled steel strip are tested, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com