High-strength steel rolling method and device

A high-strength steel and rolling force technology, applied in the field of high-strength steel rolling methods and devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

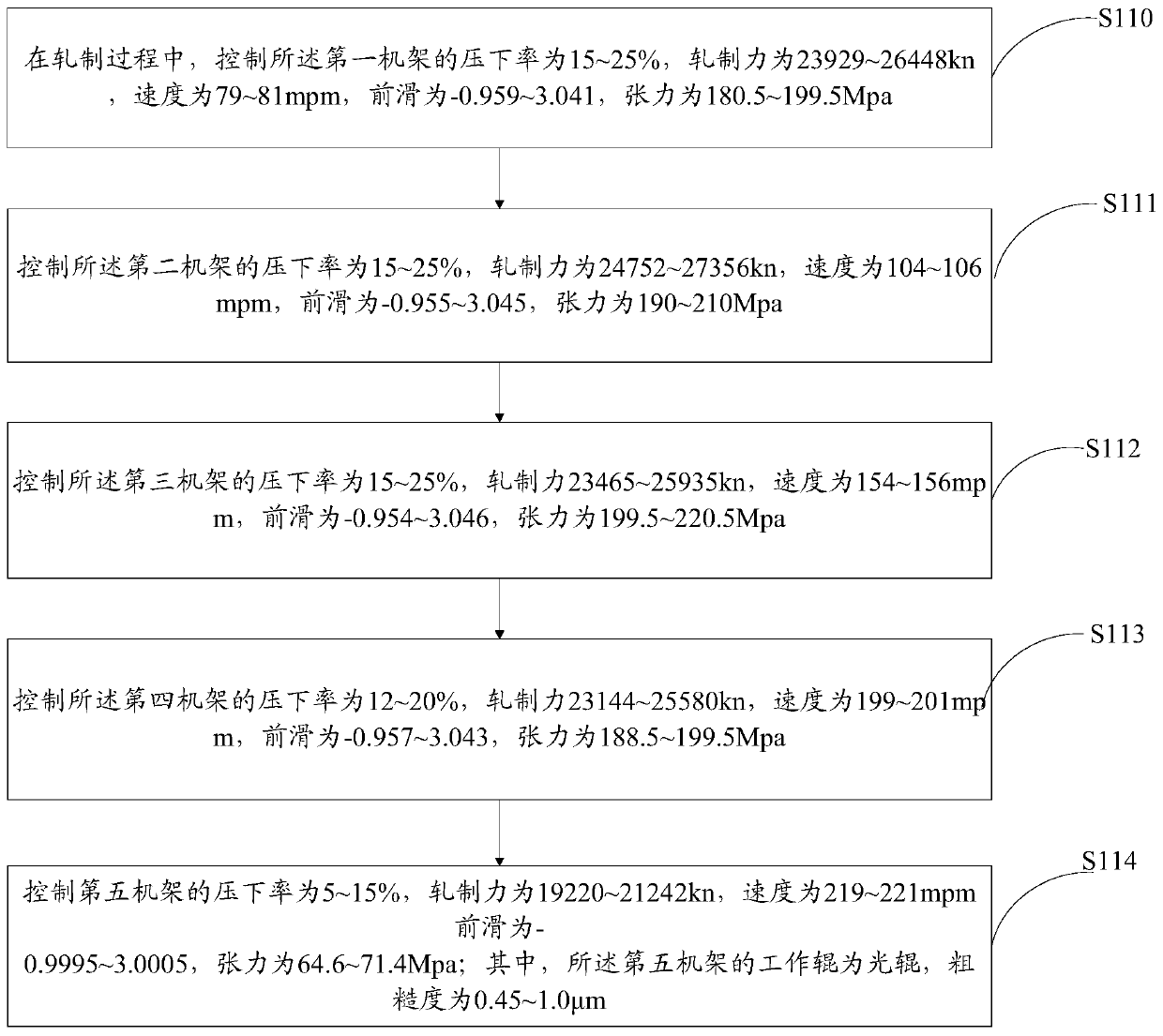

[0042] This embodiment provides a rolling method for high-strength steel, which is applied to a tandem cold rolling mill, and the tandem cold rolling mill includes: a first stand, a second stand, a third stand, a fourth stand and a fifth stand frame; such as figure 1 As shown, the method includes:

[0043] S110, during the rolling process, control the reduction ratio of the first stand to 15-25%, the rolling force to 23929-26448kn, the speed to 79-81mpm, the forward slip to -0.959-3.041, and the tension to 180.5 ~199.5Mpa;

[0044] It is necessary to start the machine before normal rolling. When starting the machine, the feedback thickness AGC control strategy for controlling the fourth stand and the fifth stand is closed. And use the raw material plate mode to start the car to ensure that the strip speed is 45mpm when the fifth rack exits after the car is started.

[0045] When starting the car, it is also necessary to control the reduction rate of the fifth stand to 90% o...

Embodiment 2

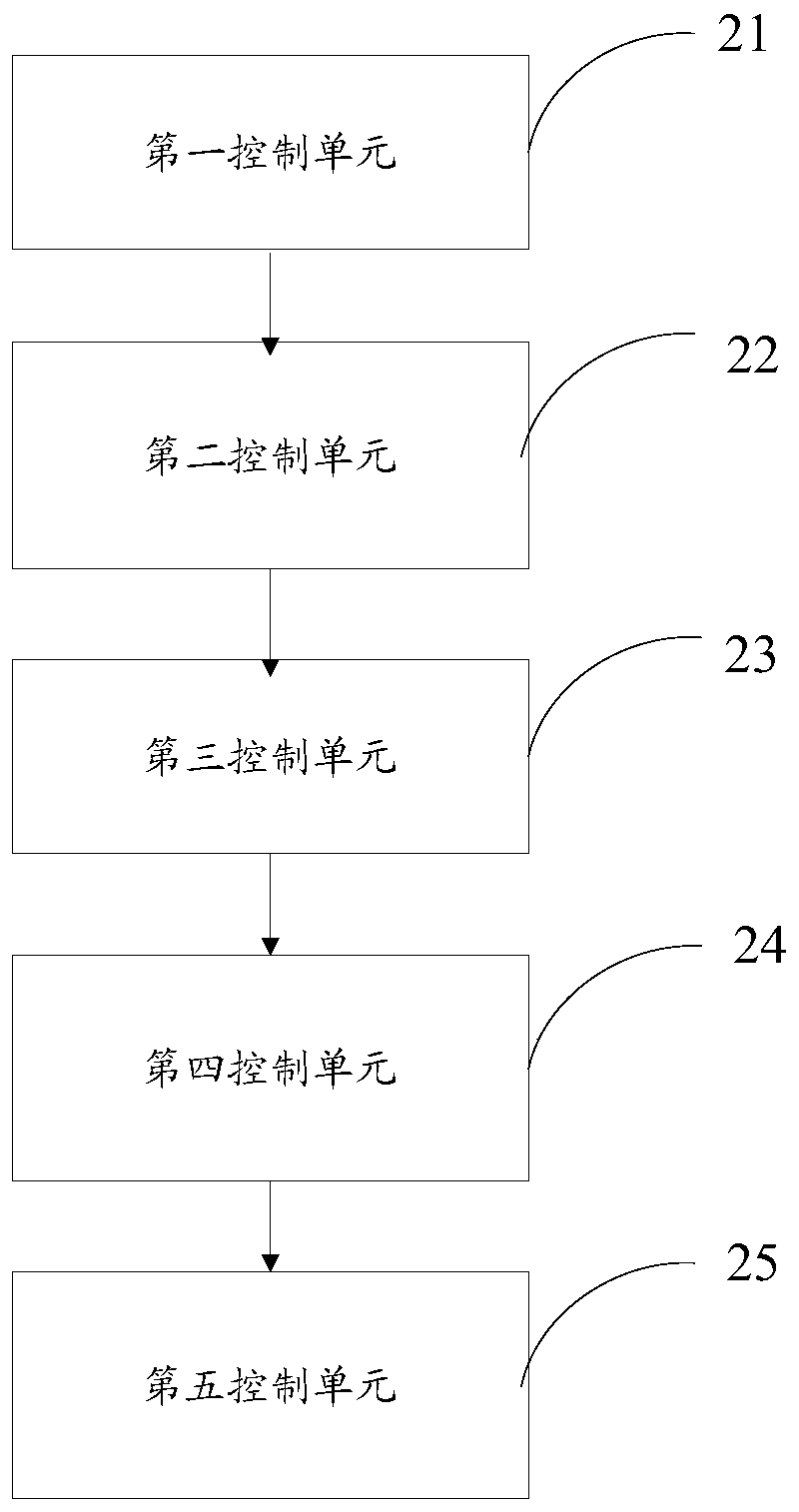

[0070] Corresponding to Embodiment 1, this embodiment also provides a rolling device for high-strength steel, such as figure 2 As shown, the device includes: a first control unit 21, a second control unit 22, a third control unit 23, a fourth control unit 24, and a fifth control unit 25;

[0071] It is necessary to start the car before normal rolling. When starting the car, the fourth control unit 24 is used to control the feedback thickness AGC control strategy of the fourth stand to be closed, and the fifth control unit 25 is used to control the AGC when starting the car. The feedback thickness AGC control strategy of the fifth rack is closed, and the raw material plate mode is used to start the car, so that after the car is started, the strip speed at the exit of the fifth rack after the car is controlled to be 45mpm. At this time, because the fifth stand uses the roll gap adjustment method to adjust the tension of the fifth stand, in order to avoid the impact of the roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

| Convexity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com