Method for controlling load balance of rolling mill for cold rolled steel strip driven by dual electrical motors

A technology of load balancing and control methods, applied in rolling mill control devices, metal rolling, roll speed control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

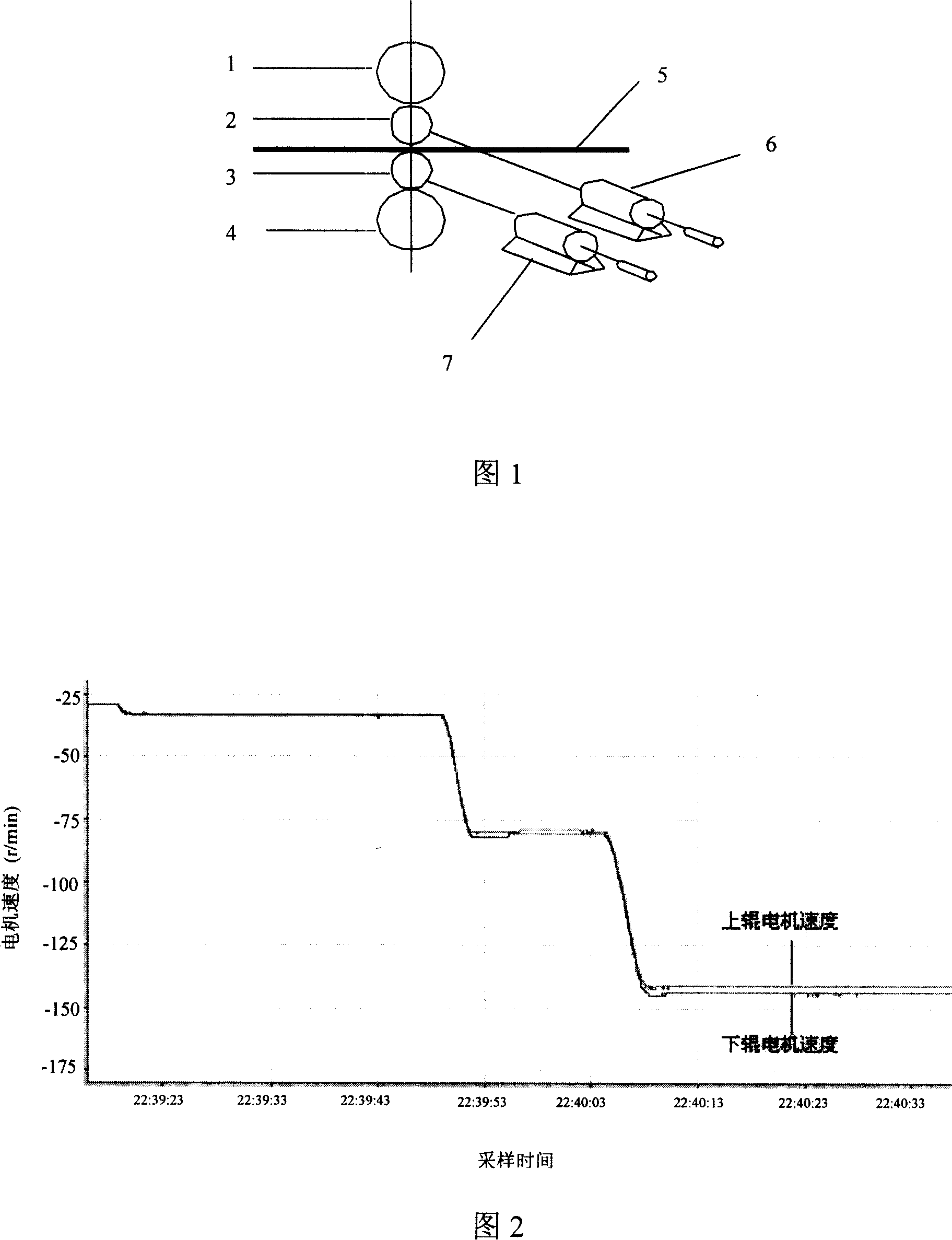

Method used

Image

Examples

Embodiment 1

[0060] The original initial roughness of the upper and lower work rolls are 0.91μm and 0.95μm respectively. The total amount of strip rolled by the work rolls during strip rolling is 1524 tons. The strip rolled steel is st12, the entrance thickness is 2.19mm, the reduction rate r is 20%, and the strip width is 1250mm. During the rolling process, the unit tension σ at the exit of the rolling mill is 120Mpa, and the acceleration of the motor during the acceleration process is 1m / s 2 .

[0061] The concentration of the emulsion is 3.25%, the temperature is 57°C, the pH value is 6.1, the electrical conductivity is 101μs / cm, the saponification value is 170mg KOH / g, the E.S.I is 51%, the injection pressure is 9.1Bar, and the work roll emulsion injection flow rate is 5140l / min .

[0062] Under the conditions of the above process parameters, the actual values of the torque and speed of the upper and lower roll drive motors during the strip rolling process are shown in Figure 2. ...

Embodiment 2

[0064] The original initial roughness of the upper and lower work rolls are respectively: 0.98μm and 0.94μm. The total amount of strip steel rolled by the work rolls during strip rolling is 2422 tons. The strip rolled steel is spcc, the entrance thickness is 2.17mm, and the strip width is 1220mm. The initial reduction rate r set by the computer is 18%, and the revised reduction rate is 0.9×18%. The unit tension σ at the exit of the rolling mill initially set by the computer is 125Mpa, the unit tension at the exit after correction is 1.15×125Mpa, and the motor acceleration is initially set at 1m / s 2, the corrected acceleration is 0.8m / s 2 .

[0065] The concentration of the emulsion is 3.5%, the temperature is 58°C, the PH value is 6.4, the conductivity is 106μs / cm, the saponification value is 173mg KOH / g, the E.S.I is 55%, the injection pressure is 9.7Bar, and the work roll emulsion injection flow rate is 5410l / min .

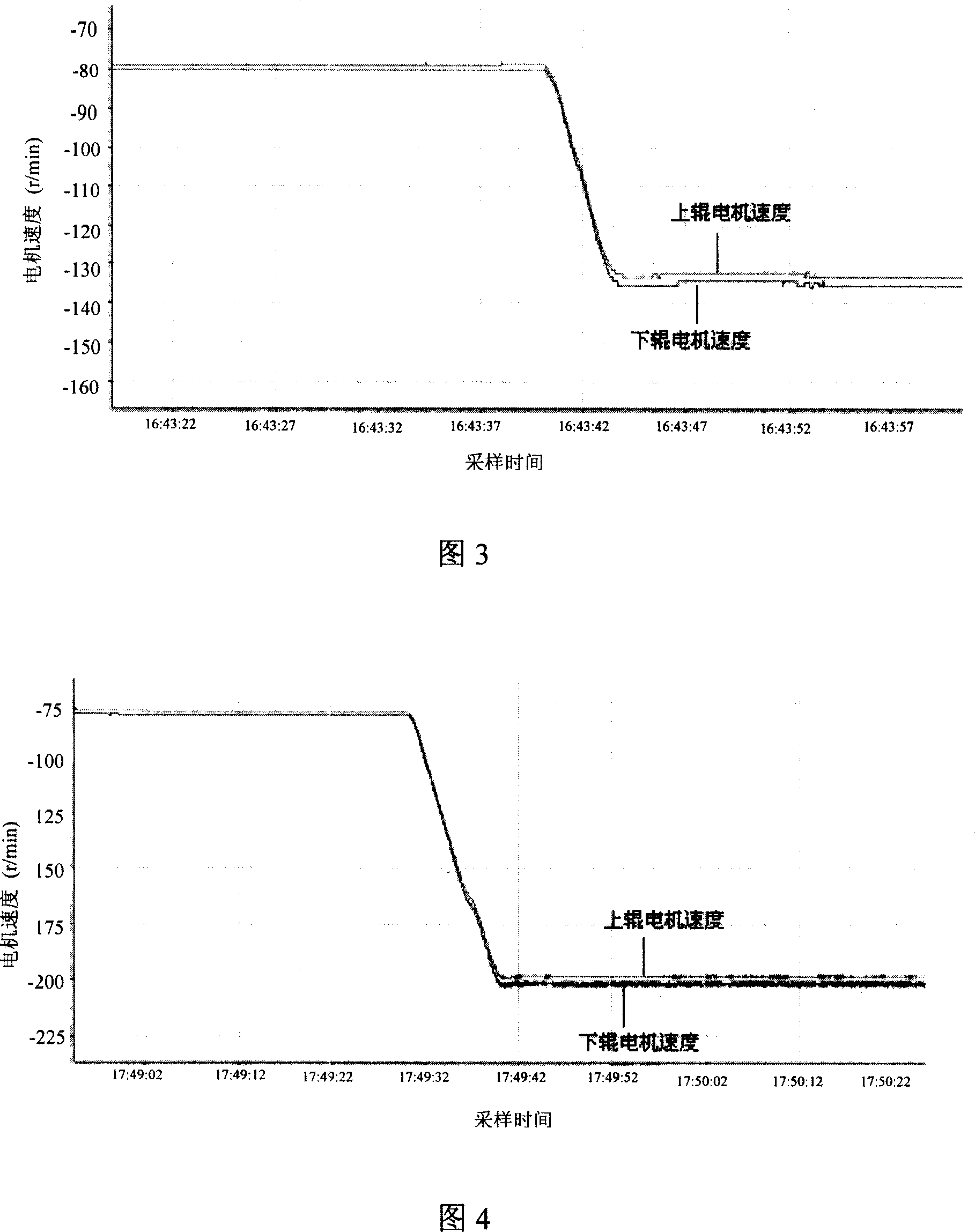

[0066] Under the conditions of the above process para...

Embodiment 3

[0068] The original initial roughness of the upper and lower work rolls: 1.04μm, 1.14μm. The total amount of strip rolled by the work rolls during strip rolling is 3104 tons. The strip rolled steel is st12, the entrance thickness is 1.15mm, and the strip width is 1225mm. The initial reduction rate r set by the computer is 33%, and the revised reduction rate is 0.7×33%. The unit tension σ at the exit of the rolling mill initially set by the computer is 125Mpa, after correction, the unit tension at the exit is 1.4×125Mpa, and the initial motor acceleration is set at 1m / s 2 , the corrected acceleration is 0.6m / s 2 .

[0069] The concentration of the emulsion is 3.5%, the temperature is 59°C, the pH value is 7.2, the electrical conductivity is 103μs / cm, the saponification value is 170mg KOH / g, the E.S.I is 51%, the injection pressure is 9.3Bar, and the work roll emulsion injection flow rate is 5141l / min .

[0070] Under the conditions of the above process parameters, the actu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saponification value | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com