Production method for rapidly cooling medium plate after rolling

A technology of rapid cooling and production method, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of reducing rolling efficiency, unable to fully exert the control of fine-grained strengthening carbonitride precipitation, and unable to obtain hardening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、25

[0010] Embodiment 1, 25mm hydropower steel (07MnCrMoVR)

[0011] The ingredients are designed as follows:

[0012] C

Si

mn

P

S

Ni

Cr

0.06

0.25

1.45

≤0.012

≤0.006

0.2

0.25

Mo

V

Ti

Nb

Alt

Ceq

0.2

0.05

0.015

0.025

0.04

≤0.44

[0013] The balance is Fe

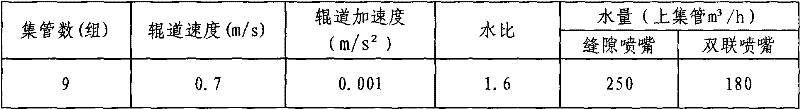

[0014] The UFC parameters are set as follows:

[0015]

[0016] The target final rolling temperature is 830°C, the start cooling temperature is 780°C, the ultra-fast cooling final cooling temperature is 450°C, the red return temperature is 510°C, and the cooling rate is 35°C / s. In comparison, the average strength is 40MPa higher than that of conventional ACC steel plates, the entire plate is cooled evenly, and the difference between the head, middle and tail of the steel plate is less than 30MPa; the impact energy at low temperature is excellent, and the average i...

Embodiment 2、17

[0018] Embodiment 2, 17.5mm pipeline steel (X70)

[0019] Use ultra-fast cooling to reduce the cost of 17.5mm pipeline steel X70, cancel the addition of 0.045% V alloy, and the composition design is as follows:

[0020] C

Si

mn

P

S

Alt

0.07

0.2

1.6

≤0.015

≤0.003

0.04

Nb

Ti

Cr

Ceq

0.055

0.015

0.25

≤0.43

[0021] The balance is Fe

[0022] The UFC parameters are set as follows:

[0023]

[0024] The rolling process adopts the ultra-fast cooling process, the target final rolling temperature is 830°C, the starting cooling temperature is 790°C, the final cooling temperature is 550°C, and the cooling rate is 40°C / s. After mass production, the ultra-fast cooling process is adopted after removing the alloying element V The comprehensive performance of the production steel plate is stable, and the cost per ton of steel is reduced by 100 yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com