A rolling pass system for special-shaped channel steel

A special-shaped groove and rolling hole technology, which is applied in the field of rolling channel steel, can solve the problems of high pass height, insufficient use of the bent leg section, and large increase in the width direction, so as to achieve small inclination of the inner side of the leg and improve the capacity of the rolling mill As well as technical and economic indicators, the effect of improving deformation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] On the φ300mm×4 tandem rolling mill, the steel grade is GBQ345, and the billet of 120×120mm is selected, and the second fire is used to form the material.

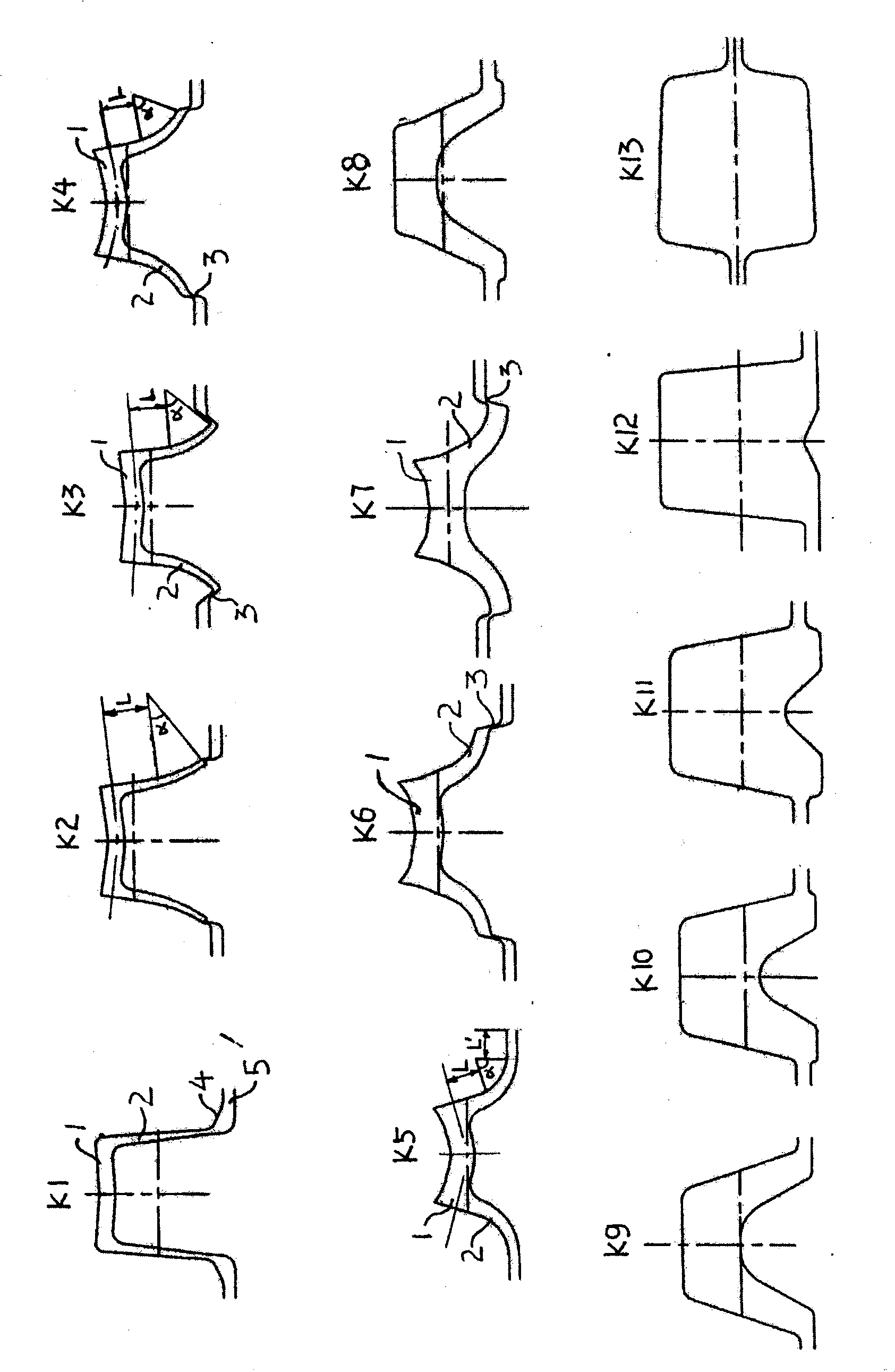

[0024] Such as figure 1 The pass system shown is designed as:

[0025] Rough rolling: box-shaped hole K13, pre-cut hole K12, deep-cut hole K11, K10, K9, K8, the slope of the side wall of each deep-cut hole is designed between 18-20%, and the above-mentioned deep-cut holes and other pass types Distributed on the first rolling mill, the reduction of each hole on the first rolling mill is larger than that of other rolling mills, the average elongation coefficient can be set to about 1.3, and the reduction of each pass should be as uniform as possible, which can reduce the subsequent The reduction amount of the pass is to reduce the problem of large pass current and rolling mill bounce, and to roll out a sufficient amount of leg length for billet opening.

[0026] Middle rolling: The middle rolling holes K7, K6, K5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com