Ti-containing medium-carbon steel, as well as method for continuous casting and continuous rolling by adopting sheet billets

A thin slab continuous casting and carbon steel technology, applied in the field of Ti-containing medium carbon steel, can solve the problems of not meeting market requirements, high cost, large plate shape, etc., and achieve the goal of reducing internal stress, reducing alloy cost, and simplifying process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

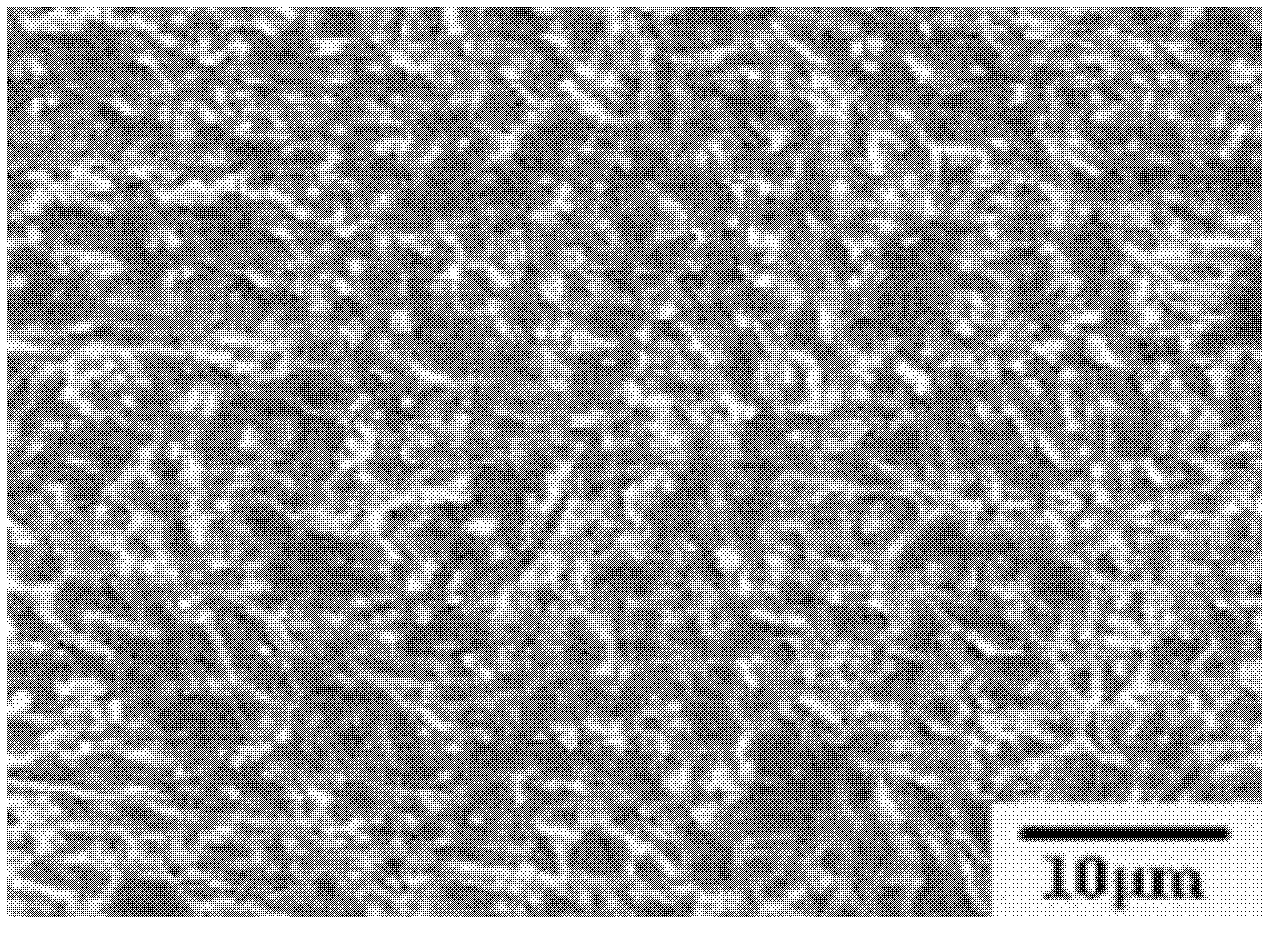

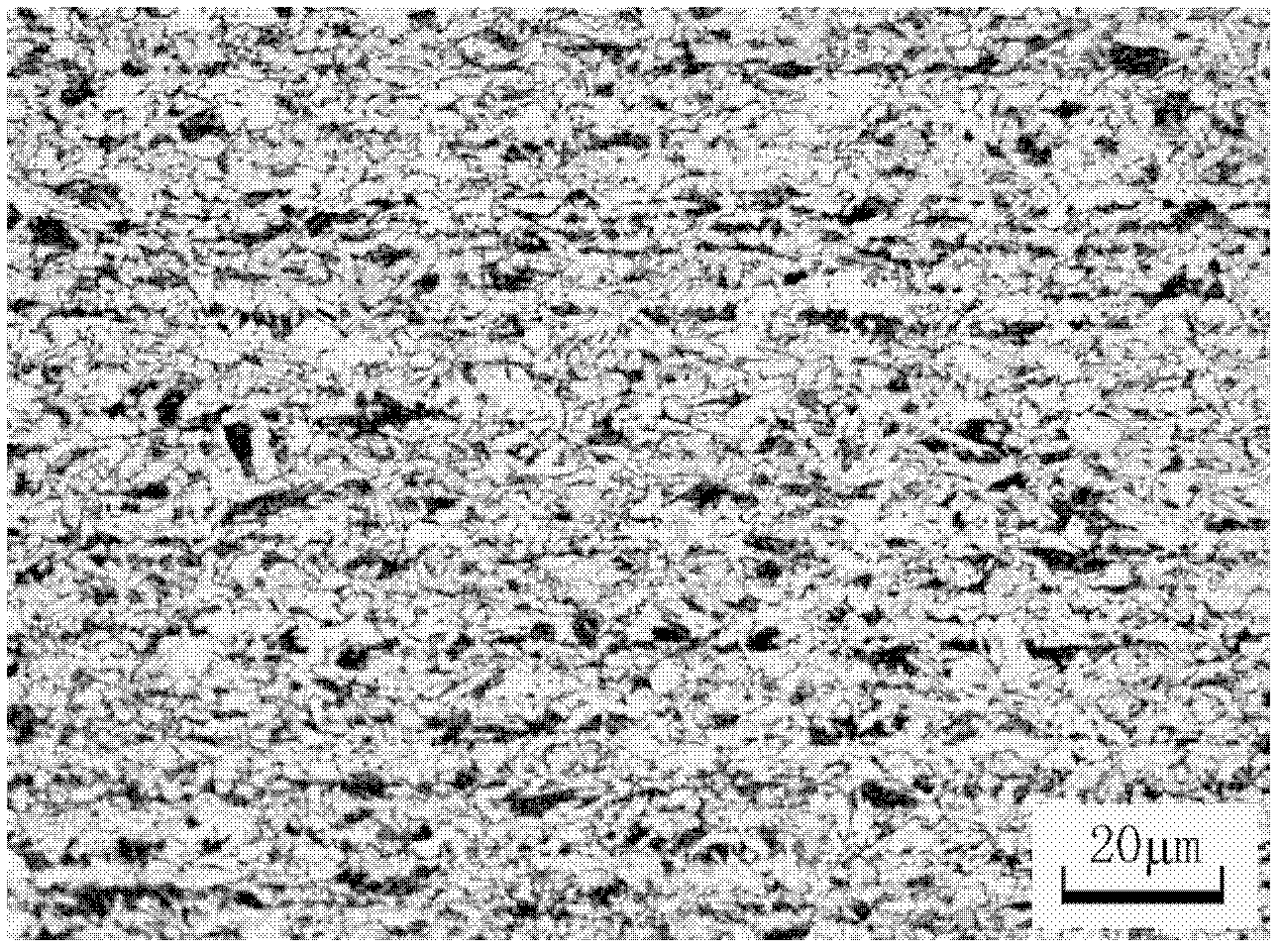

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment. The present invention has carried out 6 batches of tests altogether, adopts CSP line to carry out trial production, and its test method is carried out according to the following steps:

[0048] 1) Carry out smelting, refining outside the furnace and continuous casting into billets;

[0049] 2) Soak the slab and control: the temperature of the slab entering the furnace is 700-900°C, and the temperature of the slab out of the furnace is 1150-1250°C;

[0050] 3) Carry out rolling, and control the final rolling temperature at 860-920°C;

[0051] 4) Coil after laminar flow, and control the coiling temperature at 580-660°C;

[0052] 5) Standby.

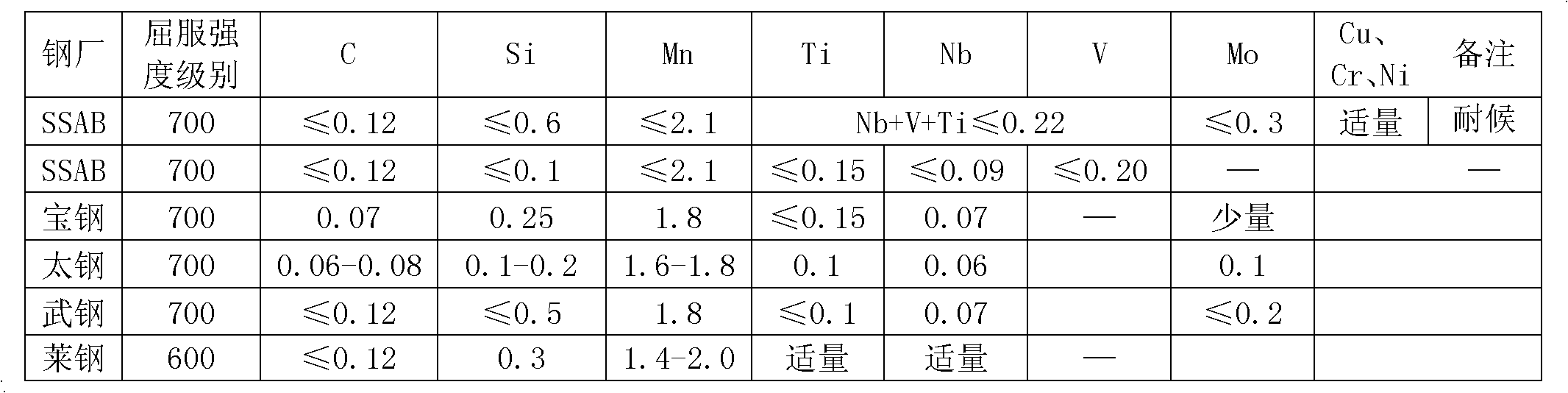

[0053] Table 1 is the chemical composition and value situation list of each embodiment of the present invention and comparative example;

[0054] Table 2 is the value-taking situation list of main technological parameters of each embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com