Aluminum alloy ring piece radial-axial rolling lubricant and lubrication process thereof

A technology of lubricants and ring blanks, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of no lubrication process, poor wear resistance, polygons and ellipses, etc., and achieve good chemical stability and lubrication Sex, reduce production cost, improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

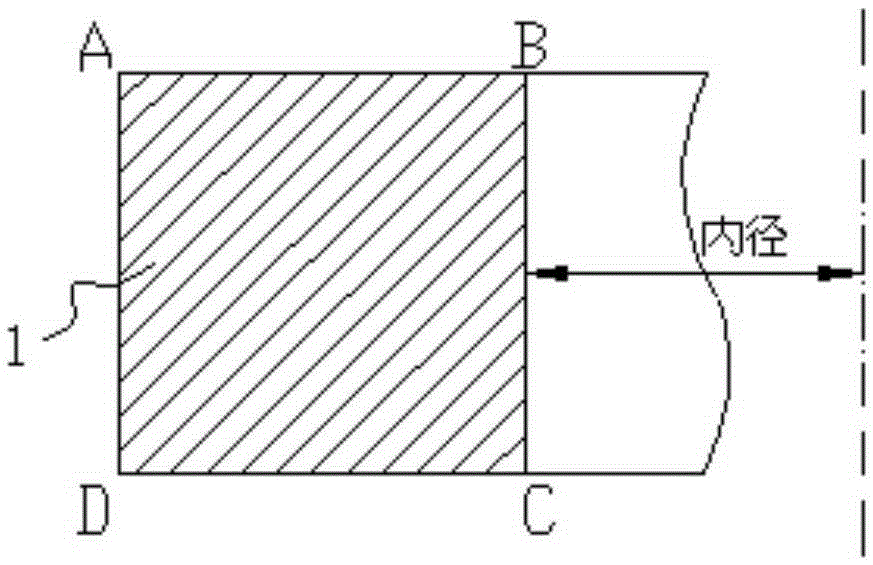

[0032] Take rolling 2219 aluminum alloy rings with an outer diameter of Φ3400mm, an inner diameter of Φ3180mm, and a ring height of 260mm as an example. The dimensional accuracy of the product is required to be ±0.002mm, the roundness required to be less than 3mm, the flatness required to be less than 3mm, and the surface quality required to be smooth without peeling , sticky roller and other defects. The size of the ring blank used is Φ1600mm in outer diameter, Φ1150mm in inner diameter, and 300mm in ring height.

[0033] Step 1: Prepare Lubricant

[0034] In terms of weight percentage, the lubricant consists of the following components: 80% of lard, 15% of graphite, 3.5% of molybdenum disulfide, and 1.5% of barium petroleum sulfonate.

[0035] Step 2: Lubrication in preparation for rolling

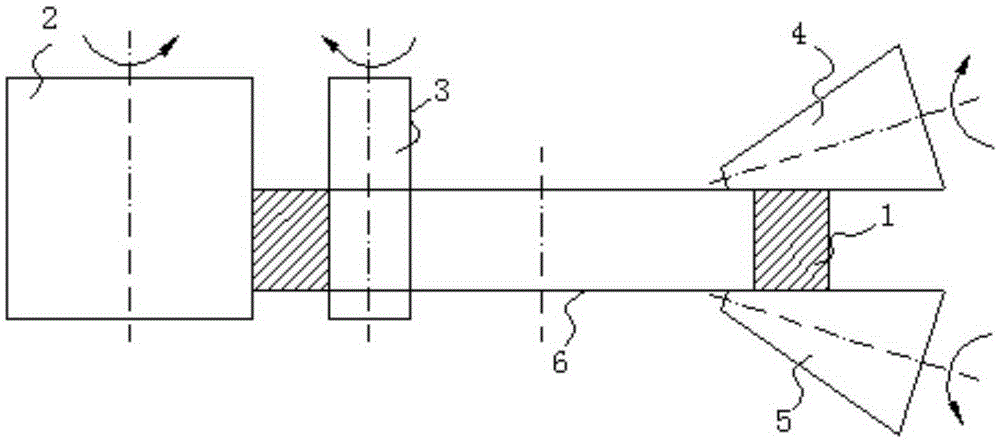

[0036] Before the ring billet is taken out from the heating furnace, the main roll 2, the core roll 3, the upper and lower tapered rolls (4 and 5) and the rolling mill table 6 of the r...

Embodiment 2

[0047] Taking rolling 7A04 aluminum alloy rings with outer diameter Φ3520mm, inner diameter Φ3280mm, and ring height 180mm as an example, the product size accuracy requirements are ±2 / 1000mm, the roundness requirements are less than 3mm, the flatness requirements are less than 3mm, and the surface quality is required to be smooth and free from scratches. Defects such as leather and sticky rollers. The size of the ring blank used is Φ1600mm in outer diameter, Φ1160mm in inner diameter, and 230mm in ring height.

[0048] Step 1: Prepare Lubricant

[0049] Calculated by weight percentage, the lubricant is composed of the following components: 65% of lard oil, 30% of graphite, 4.5% of molybdenum disulfide and 0.5% of barium petroleum sulfonate.

[0050] Step 2: Lubrication in preparation for rolling

[0051] Before the ring billet is taken out from the heating furnace, the main roll 2, the core roll 3, the upper and lower tapered rolls (4 and 5) and the rolling mill table 6 of t...

Embodiment 3

[0062] The only difference with the above-mentioned embodiment 2 or embodiment 1 is: step 1: prepare lubricant

[0063] Calculated by weight percentage, the lubricant consists of the following components: 70% of lard oil, 23% of graphite, 4% of molybdenum disulfide and 0.8% of barium petroleum sulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com